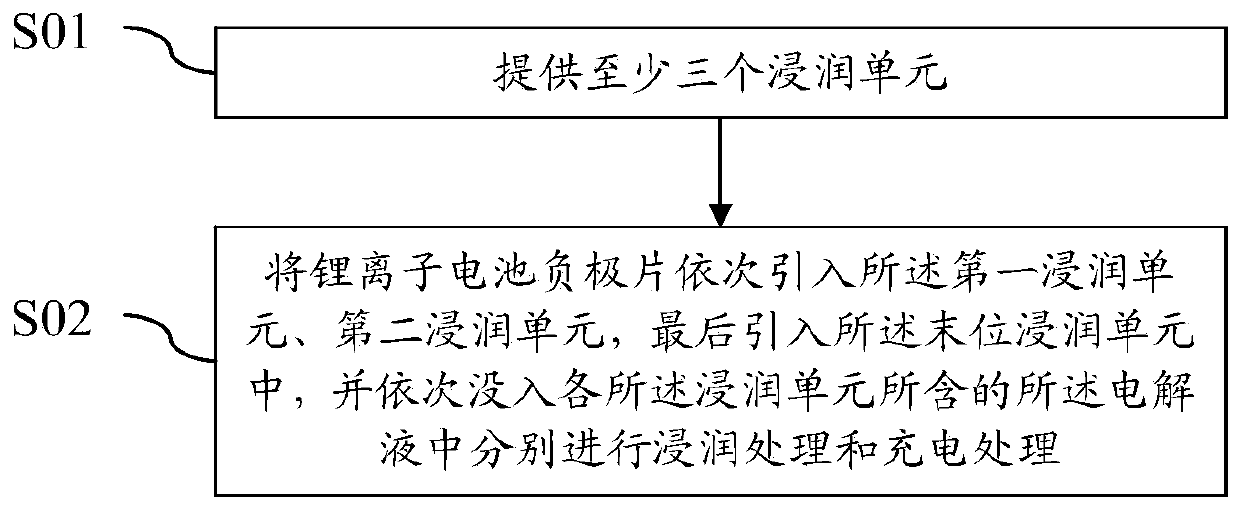

Step-by-step pre-lithiation method of lithium-ion battery negative plate

A lithium-ion battery and pre-lithiation technology, applied in the field of lithium-ion batteries, can solve the problems of unsatisfactory accuracy and uniformity environmental control, low efficiency, etc., to improve the efficiency and safety of pre-lithiation, and easily control the process conditions. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

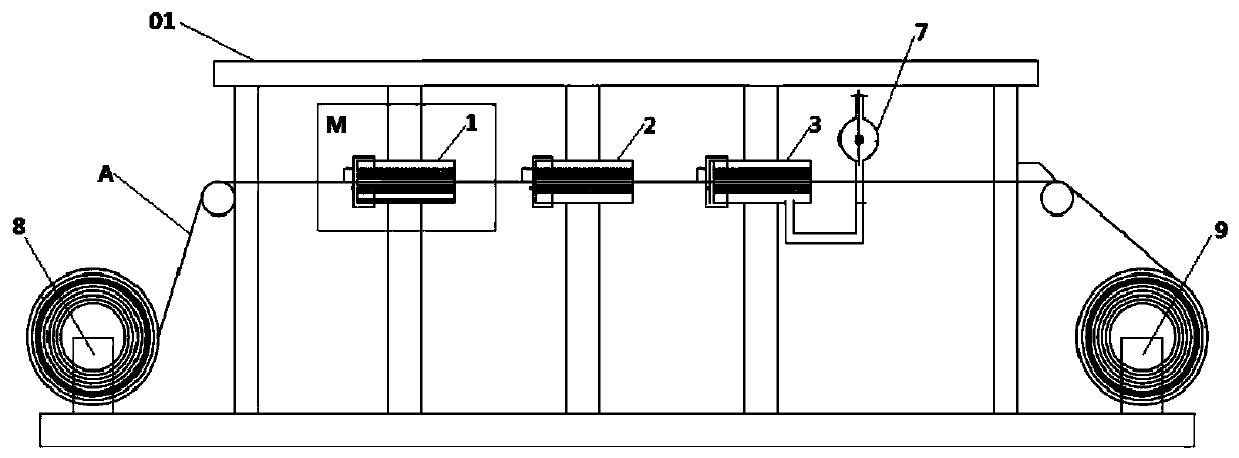

[0061] This embodiment provides a step-by-step pre-lithiation method for a silicon-carbon negative electrode sheet. The step-by-step pre-lithiation method of the silicon carbon negative plate comprises the following steps:

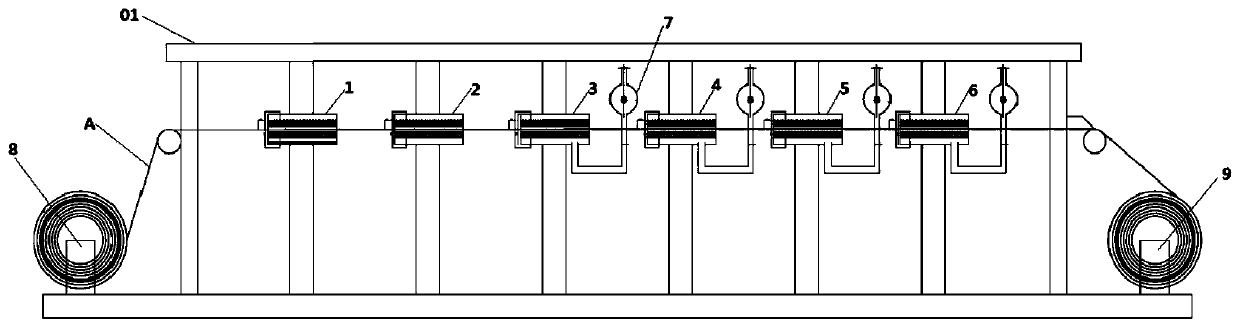

[0062] Pass the silicon carbon negative electrode sheet to be treated sequentially through such as image 3 The shown pre-lithiation unit 1, pre-lithiation unit 2, pre-lithiation unit 3, pre-lithiation unit 4, pre-lithiation unit 5, and pre-lithiation unit 6 are respectively subjected to infiltration treatment and charging treatment,

[0063] Wherein, the composition that the electrolytic solution that pre-lithiation unit 1 comprises comprises is as follows:

[0064] Lithium salt: LiPF 6 0.9mol / L;

[0065] Film-forming additive: a mixture of fluoroethylene carbonate (FEC) and lithium difluorooxalate borate (LiODFB) with a mass ratio of 1:1, with a total content of 3%;

[0066] Solvent: a mixture of ethylene carbonate (EC) and propylene carbonate (PC) ...

Embodiment 2

[0084] This embodiment provides a step-by-step pre-lithiation method for a silicon-carbon negative electrode sheet. The step-by-step pre-lithiation method of the silicon carbon negative plate comprises the following steps:

[0085] Pass the silicon carbon negative electrode sheet to be treated sequentially through such as image 3 The shown pre-lithiation unit 1, pre-lithiation unit 2, pre-lithiation unit 3, pre-lithiation unit 4, pre-lithiation unit 5, and pre-lithiation unit 6 are respectively subjected to infiltration treatment and charging treatment,

[0086] Wherein, the composition that the electrolytic solution that pre-lithiation unit 1 comprises comprises is as follows:

[0087] Lithium salt: LiPF 6 0.5mol / L;

[0088] Film-forming additive: a mixture of fluoroethylene carbonate (FEC) and lithium difluorooxalate borate (LiODFB) with a mass ratio of 1:1, with a total content of 6%;

[0089] Solvent: a mixture of ethylene carbonate (EC) and propylene carbonate (PC) ...

Embodiment 3

[0106] This embodiment provides a step-by-step pre-lithiation method for a silicon-carbon negative electrode sheet. The step-by-step pre-lithiation method of the silicon carbon negative plate comprises the following steps:

[0107] Pass the silicon carbon negative electrode sheet to be treated sequentially through such as image 3 The shown pre-lithiation unit 1, pre-lithiation unit 2, pre-lithiation unit 3, pre-lithiation unit 4, pre-lithiation unit 5, and pre-lithiation unit 6 are respectively subjected to infiltration treatment and charging treatment,

[0108] Wherein, the composition that the electrolytic solution that pre-lithiation unit 1 comprises comprises is as follows:

[0109] Lithium salt: LiPF 6 1.2mol / L;

[0110] Film-forming additive: a mixture of fluoroethylene carbonate (FEC) and lithium difluorooxalate borate (LiODFB) with a mass ratio of 3:1, with a total content of 0.2%;

[0111] Solvent: a mixture of ethylene carbonate (EC) and propylene carbonate (PC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com