A method for supplementing lithium by radiation and the electrode, winding core and battery it includes

A lithium battery, lithium ion battery technology, applied in secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of safety accidents and high chemical activity of metal lithium, and achieve improved safety, uniform lithium replenishment, and flexible timing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

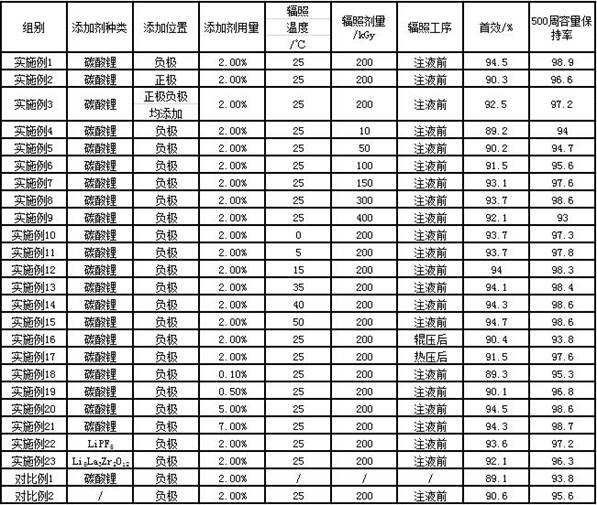

Examples

Embodiment 1

[0038] Preparation of positive electrode sheet for lithium ion battery:

[0039] Mix the positive electrode active material lithium iron phosphate, conductive carbon, and binder PVDF in the solvent NMP according to the mass ratio of 95:3:2, and stir evenly to obtain the positive electrode slurry. The obtained positive electrode slurry is coated on a 13 μm aluminum foil, dried, and cold pressed to obtain a compacted density of 2.35 g / cm 3 The pole piece is then die-cut to obtain the positive pole piece.

[0040] Preparation of lithium ion battery negative electrode sheet:

[0041] Add the negative electrode active material natural graphite, lithium-containing precursor lithium carbonate, conductive carbon, thickener CMC, and binder SBR into the solvent deionized water according to the mass ratio of 95:1.9:1:2:2 (the additive dosage in this embodiment 2%), after mixing evenly, the negative electrode slurry is obtained, and then the negative electrode slurry is coated on both s...

Embodiment 2

[0048] The difference from Example 1 is that the addition position of the lithium-containing additive is the positive electrode:

[0049] Preparation of positive electrode sheet for lithium ion battery:

[0050] Mix the positive electrode active material lithium iron phosphate, lithium-containing precursor lithium carbonate, conductive carbon, and binder PVDF in the solvent NMP according to the mass ratio of 95:1.9:3:2, and stir evenly to obtain the positive electrode slurry. The obtained positive electrode slurry is coated on a 13 μm aluminum foil, dried, and cold pressed to obtain a compacted density of 2.35 g / cm 3 The pole piece is then die-cut to obtain the positive pole piece.

[0051] Preparation of lithium ion battery negative electrode sheet:

[0052] Add the negative electrode active material natural graphite, conductive carbon, thickener CMC, and binder SBR into the solvent deionized water according to the mass ratio of 95:1:2:2. After mixing evenly, the negative e...

Embodiment 3

[0059] The difference from Example 2 is that the addition position of the lithium-containing additive is that both the positive electrode and the negative electrode are added:

[0060] Preparation of positive electrode sheet for lithium ion battery:

[0061] Mix the positive electrode active material lithium iron phosphate, lithium-containing precursor lithium carbonate, conductive carbon, and binder PVDF in the solvent NMP according to the mass ratio of 95:1.9:3:2, and stir evenly to obtain the positive electrode slurry. The obtained positive electrode slurry is coated on a 13 μm aluminum foil, dried, and cold pressed to obtain a compacted density of 2.35 g / cm 3 The pole piece is then die-cut to obtain the positive pole piece.

[0062] Add the negative electrode active material natural graphite, lithium-containing precursor lithium carbonate, conductive carbon, thickener CMC, and binder SBR into the solvent deionized water according to the mass ratio of 95:1.9:1:2:2 (the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com