A composite polymer three-dimensional structure metal lithium electrode and lithium ion battery

A composite polymer and three-dimensional structure technology, which is applied in the field of composite polymer three-dimensional structure metal lithium electrodes and lithium-ion batteries, can solve the problems of capacity loss, fast capacity decay, interface fluctuations, etc., and achieve improved volume ratio energy density and mass ratio Energy density, improving charge and discharge efficiency, and avoiding the effect of dead lithium problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. Please note that the embodiments described below are exemplary only for explaining the present invention, and should not be construed as limiting the present invention.

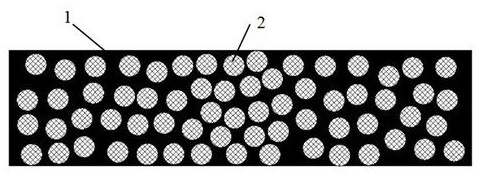

[0027] Such as figure 1 As shown, the metal lithium electrode with a composite polymer three-dimensional structure provided by the present invention includes a polymer film 1, an electronically conductive material, an ion-conductive material, and metallic lithium, wherein the polymer film is used as a matrix, and the electronically conductive material and ion-conductive material are doped in the Wherein, it is in a state of uniform distribution; the polymer membrane has a porous structure, and metal lithium 2 is filled in the pores of the polymer membrane.

[0028] According to the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com