mvr rectification stripping compound device and its process method

A composite device and rectification technology, applied in the field of rectification process, can solve the problems of reduced energy saving effect, difficult separation requirements, low compressor operation efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

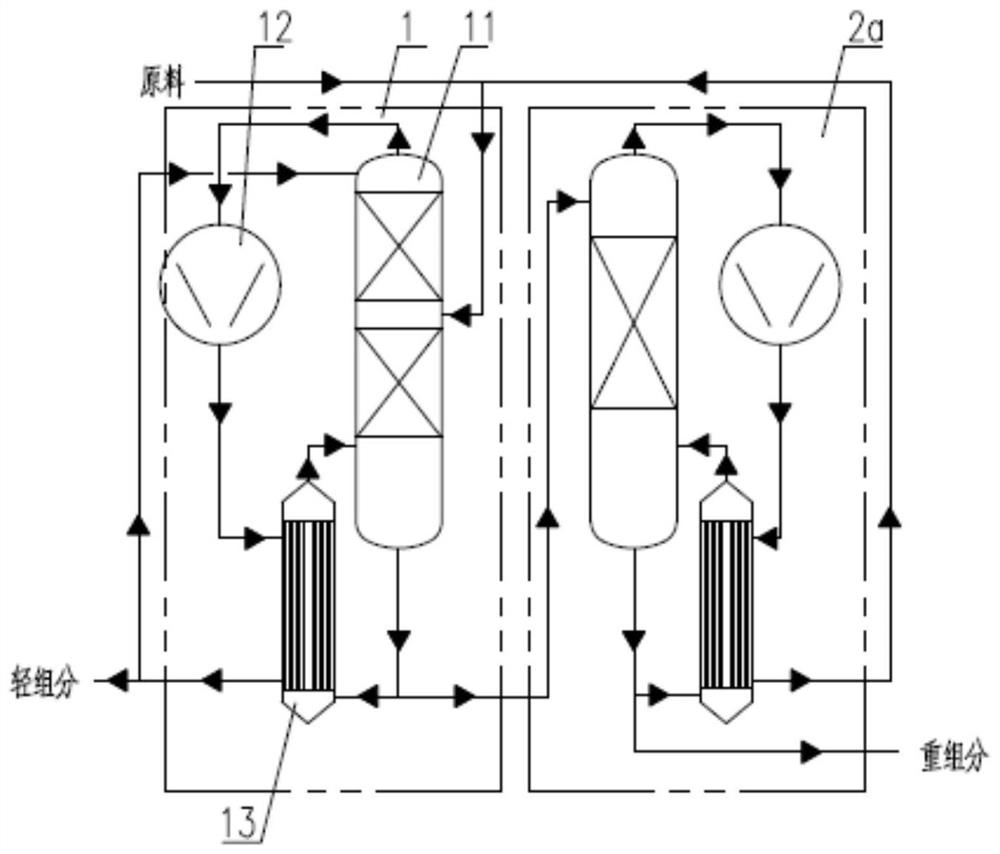

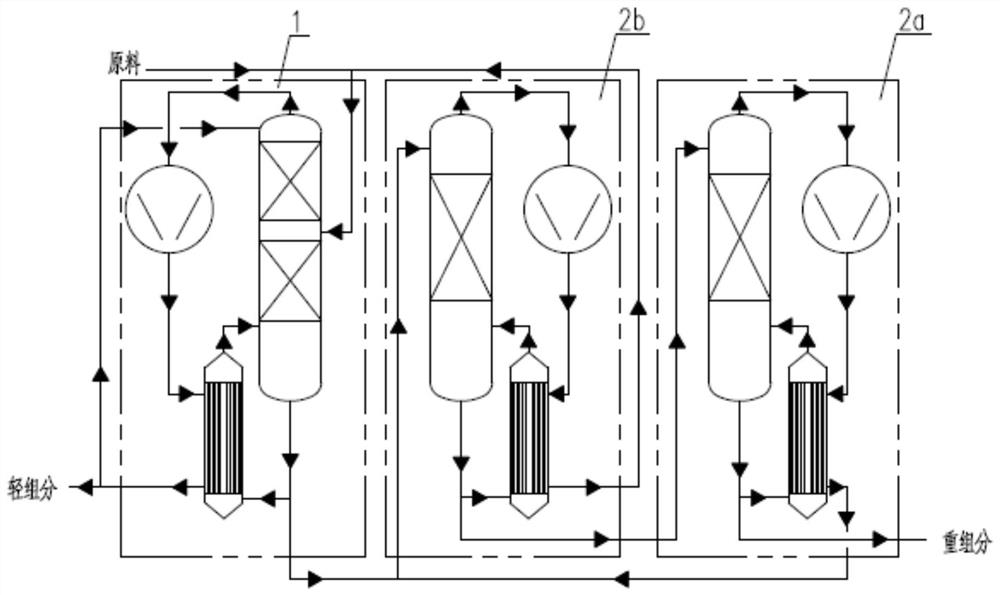

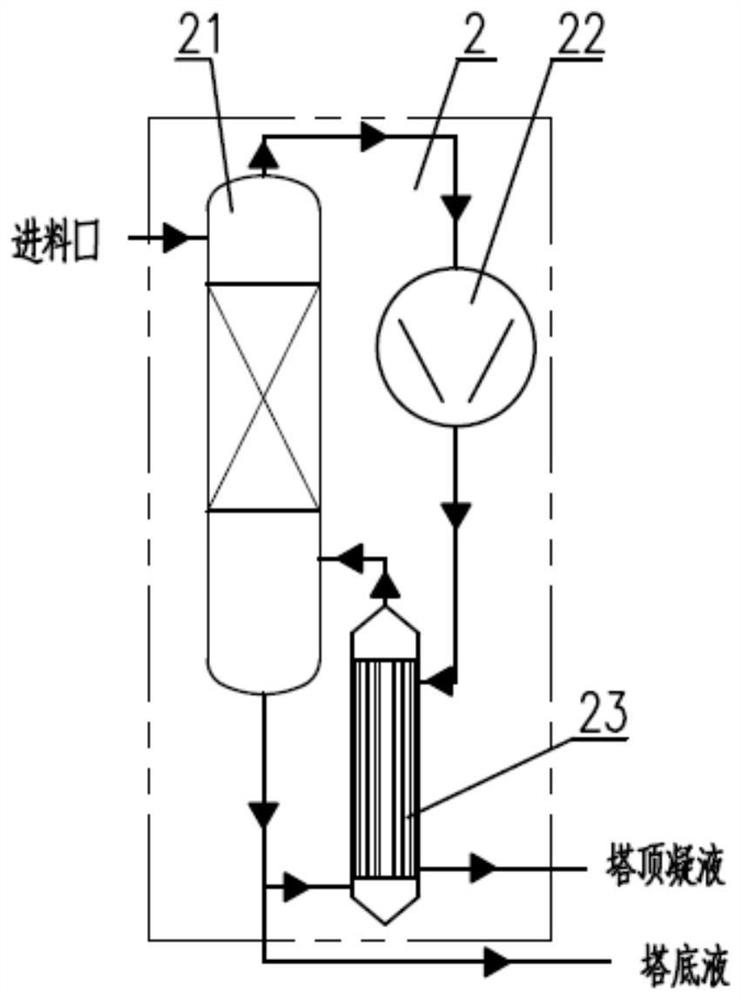

[0038] The MVR rectification and distillation compound device includes a one-stage MVR rectification unit and a multi-stage MVR stripping unit, and the MVR rectification unit and the multi-stage MVR stripping unit are connected in series along the flow direction of the raw material, and the raw material first flows through The MVR rectification unit then flows through the multi-stage MVR stripping unit. For the multi-stage MVR stripping unit series system, the MVR stripping unit that the raw material flows through first is the upper-level MVR stripping unit, and the MVR stripping unit that the raw material flows through afterward. The distillation unit is the next-level MVR stripping unit. The configuration stages of the MVR stripping unit are determined according to the requirements of raw material composition and separation purity. According to the location of the MVR stripping unit, it is divided into the final MVR stripping unit and the intermediate Level MVR stripping unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com