Electrical connector

A technology of electrical connectors and sockets, which is applied in the direction of connection, two-part connection devices, circuits, etc., can solve the problems of reduced service life, poor structural strength, structural strength fracture, etc., and achieve improved structural strength, large bonding force, The effect of multiple contact areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

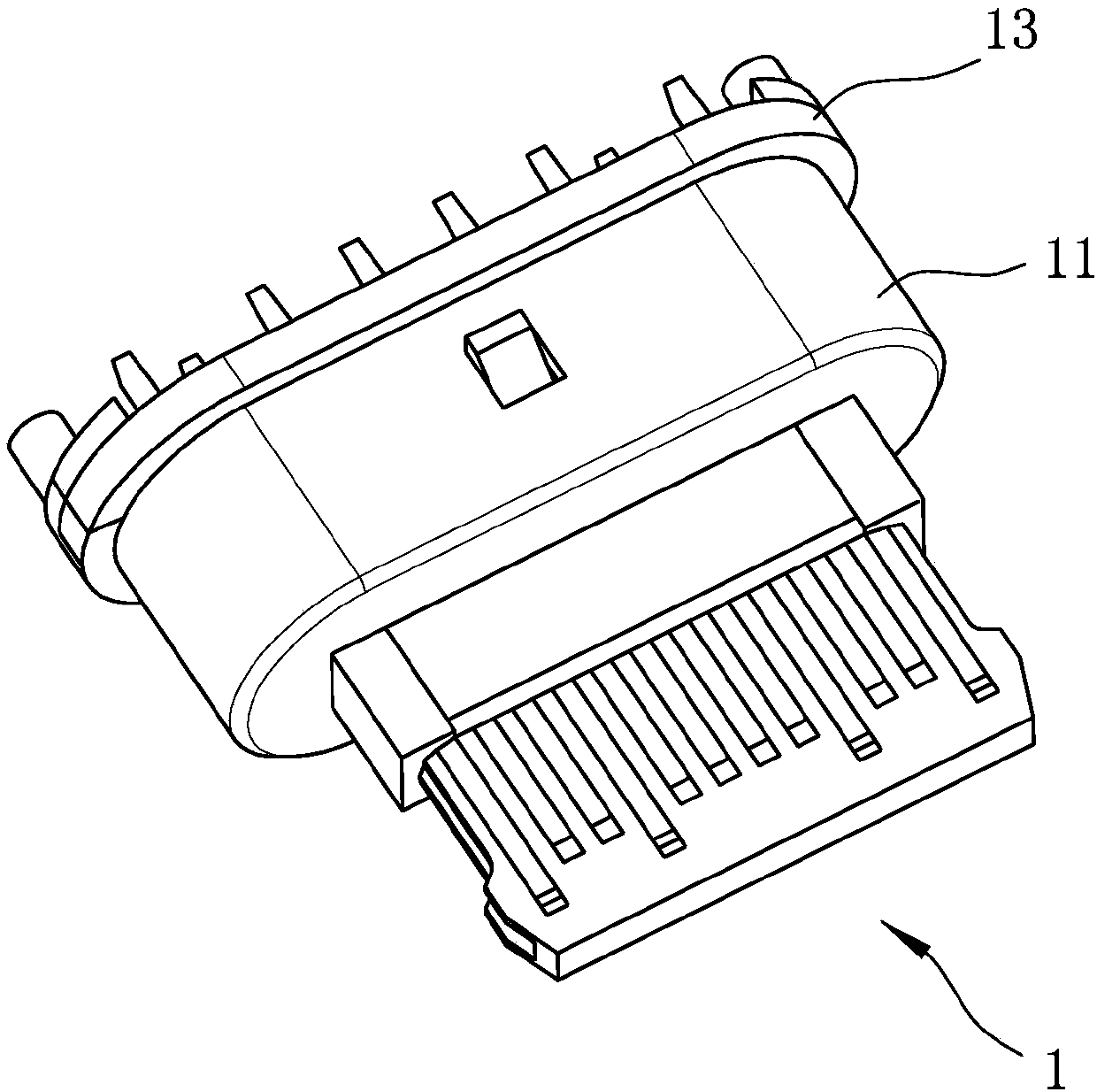

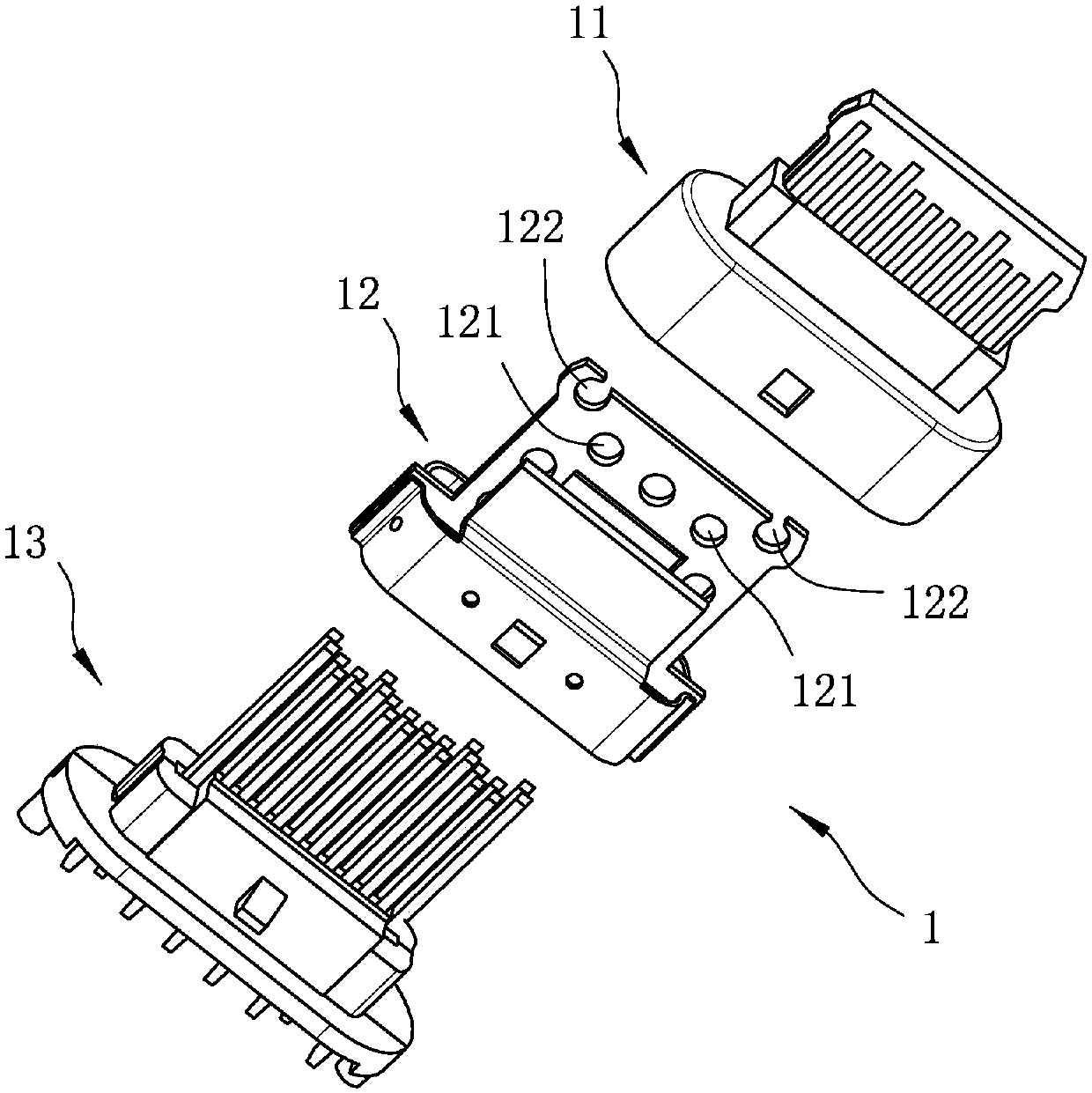

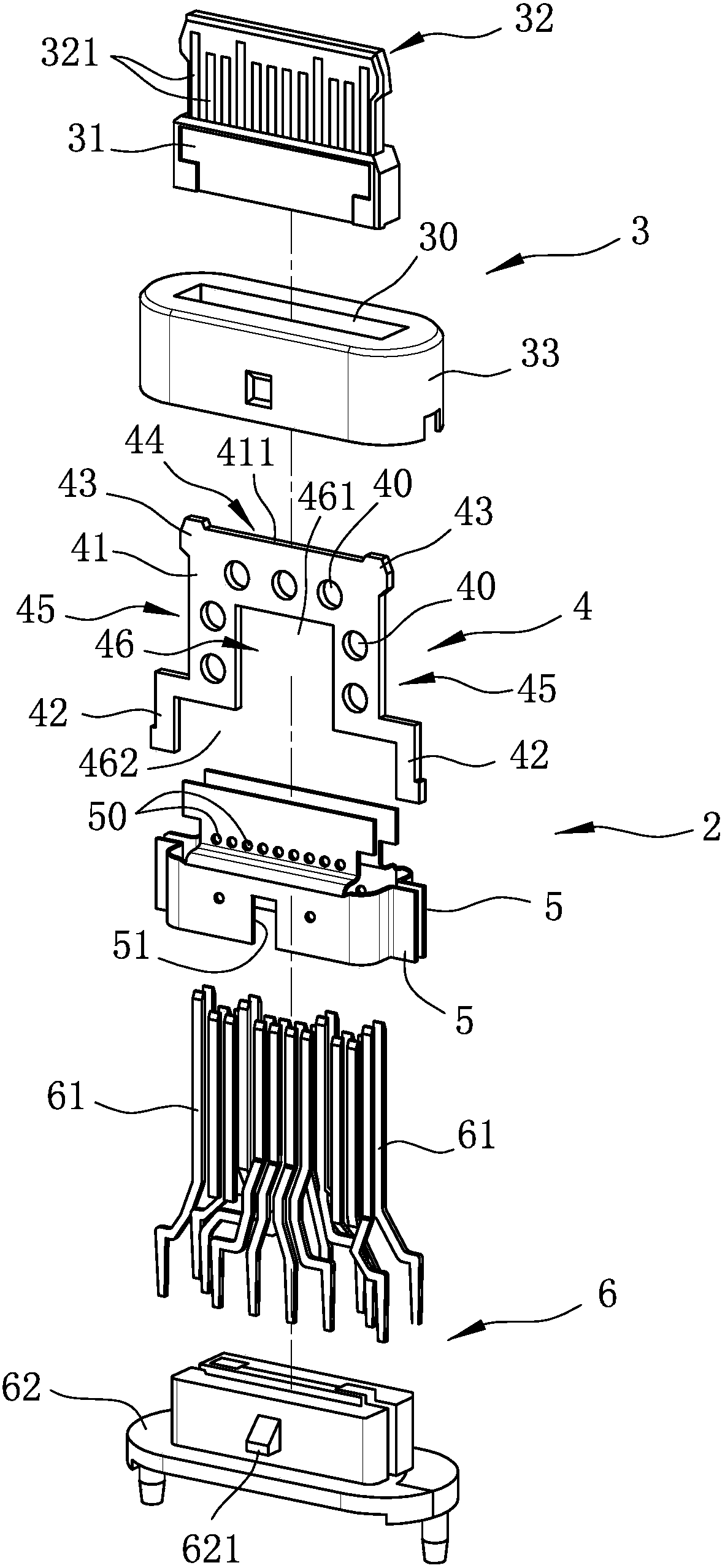

[0025] refer to image 3 , Figure 4 and Figure 5 The first embodiment of the electrical connector 2 of the present invention includes a socket 3 made by plastic injection molding and surrounding a setting space 30 , inserted into the setting space 30 of the socket 3 and opening a plurality of channels The frame 4 of the hole 40, two clamping parts 5 that cooperate with each other to clamp the frame 4 up and down and open a plurality of openings 50 continuously along the left and right directions, and the frame 4 is sandwiched and arranged on the receiving seat 3 terminal module 6 on the The socket 3 includes a base 31 , a plate body 32 protruding forward from the front end of the base 31 , and an insulation sleeve that is sleeved on the base 31 and defines the installation space 30 together with the base 31 . Section 33. The board portion 32 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap