Jacking pipe joint inner wall concrete stress monitoring method based on optical fiber sensing

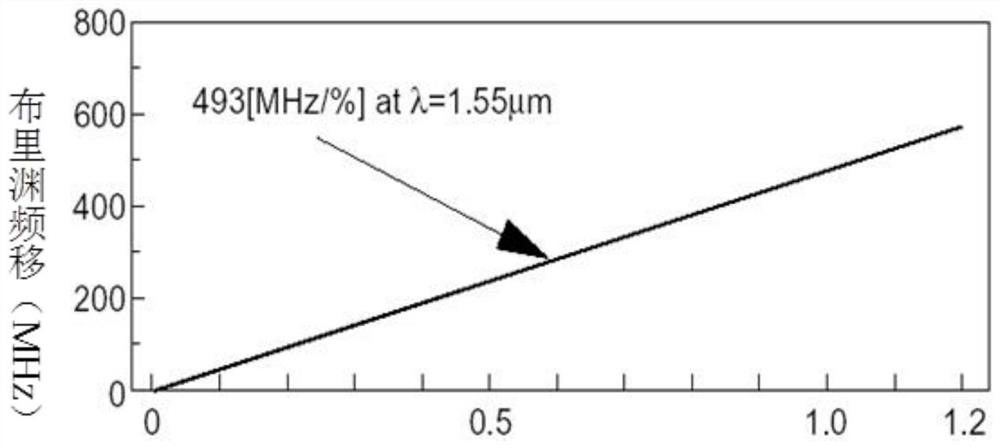

An optical fiber sensing and stress monitoring technology, which is applied in the direction of force measurement, measurement force, and measurement device by measuring the change of optical properties of materials when they are stressed. problems such as location, affecting the construction progress of the pipe jacking project, etc., to achieve the effects of light weight, long monitoring distance and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

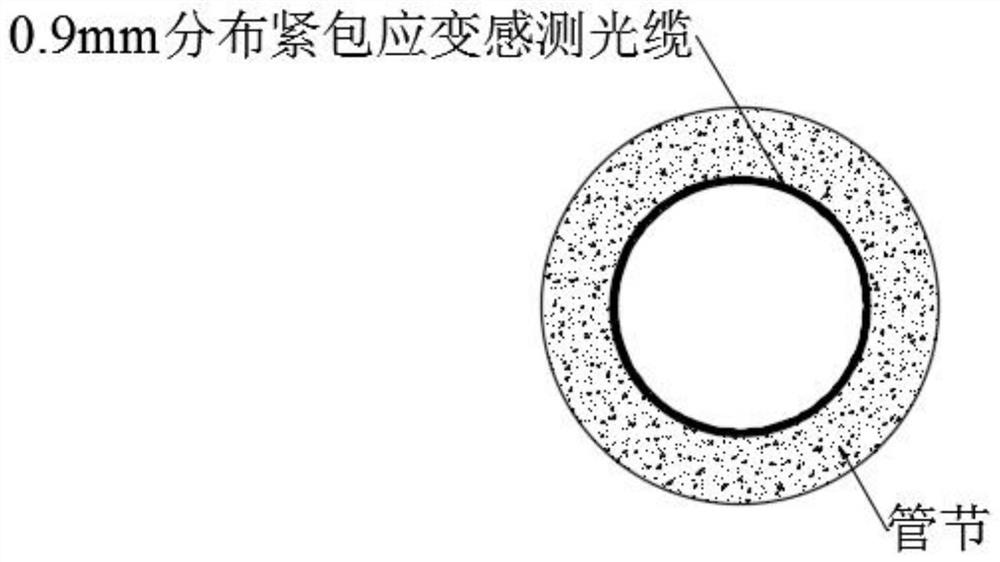

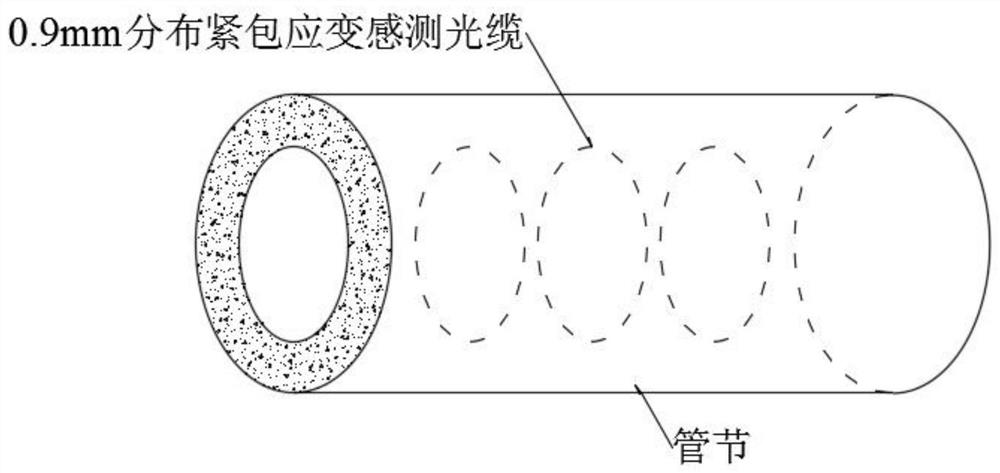

[0036] like Figure 1-2 As shown, a method for monitoring concrete stress on the inner wall of pipe jacking pipe joints based on optical fiber sensing includes the following steps:

[0037] S1. Clean the surface of the structure where the optical cable is laid on the three sections of the pipe section, remove impurities and make an indicator line on the surface of the structure, and paint a layer of epoxy resin glue on the indicator line according to a certain width;

[0038] S2. Lay out 0.9mm glass fiber composite base optical cable along one direction on the glue, and press the dense optical cable with rollers to make the optical cable fully contact with the glue;

[0039] S3. After the optical cable is laid, apply a layer of epoxy glue on the upper part of the optical cable again, press it tightly with a roller again, and then use cloth tape to temporarily fix the optical cable to prevent the optical cable from falling off. After the epoxy glue is cured for about 24 hours, ...

Embodiment 2

[0054] like Figure 1-2 As shown, a method for monitoring concrete stress on the inner wall of pipe jacking pipe joints based on optical fiber sensing includes the following steps:

[0055]S1. Clean the surface of the structure where the optical cable is laid on the three sections of the pipe section, remove impurities and make an indicator line on the surface of the structure, and paint a layer of epoxy resin glue on the indicator line according to a certain width;

[0056] S2. Lay out 0.9mm glass fiber composite base optical cable along one direction on the glue, and press the dense optical cable with rollers to make the optical cable fully contact with the glue;

[0057] S3. After the optical cable is laid, apply a layer of epoxy glue on the upper part of the optical cable again, press it tightly with a roller again, and then use cloth tape to temporarily fix the optical cable to prevent the optical cable from falling off. After the epoxy glue is cured for about 24 hours, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com