Butyronitrile insulation layer material with high elongation and ablation resistance and preparation method of butyronitrile insulation layer material

A high-elongation, ablation-resistant technology, applied in the field of structural thermal insulation layers, which can solve the problems of high thermal decomposition temperature, material burning, and large filling coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

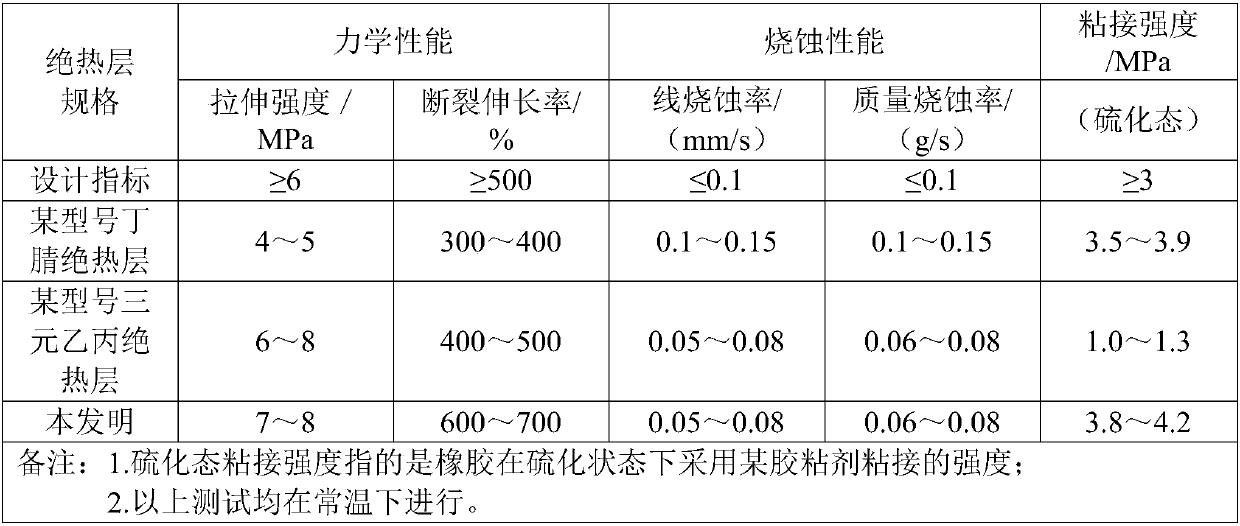

Examples

preparation example Construction

[0027] The preparation process of the thermal insulation layer material of the present invention is as follows:

[0028] 1) According to the ratio, ingredients;

[0029] 2) Dry the weighed aramid chopped fiber and white carbon black at 80°C for 1 hour;

[0030] 3) Pass the weighed nitrile rubber on the mill for 5 to 8 times;

[0031] 4) Add zinc oxide, stearic acid, silicon carbide, boron phenolic resin, decabromodiphenyl ether, and antimony trioxide to nitrile rubber in sequence, and the roller distance is 3 mm; cut the rubber and roll 3 times;

[0032] 5) Add white carbon black and dioctyl sebacate several times, the roller distance is 3mm; cut glue and roll 3 times;

[0033] 6) Add aramid chopped fiber several times, cut glue and roll 3 times, the roller distance is 3mm;

[0034] 7) Thin pass 2 times, the roller distance is 0.3mm, and then the roller distance is 3mm, cut the rubber and roll 2 times; repeat this step 3 times;

[0035] 8) Add dicumyl peroxide, roll distan...

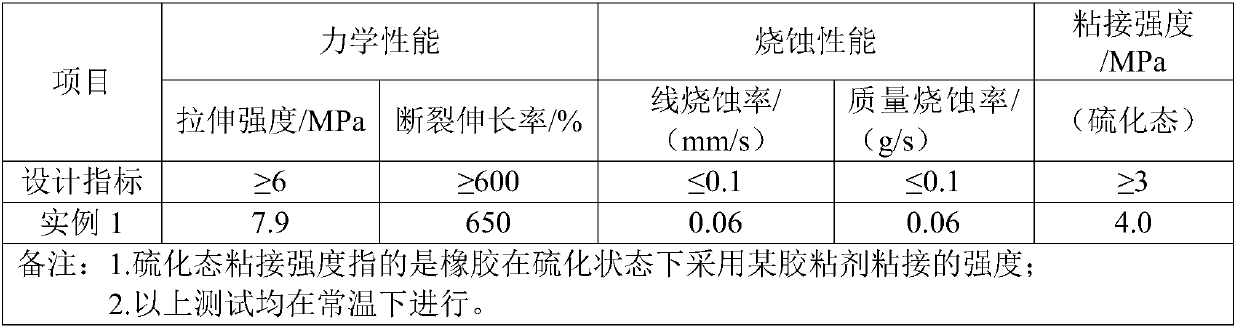

example 1

[0041] (1) Weigh each component of the formula

[0042] Weigh the ingredients of the formula according to the table below.

[0043]

[0044] (2) heat insulation layer refining

[0045] a) Dry the weighed aramid chopped fiber and white carbon black at 80°C for 1 hour;

[0046] b) Thinly pass the nitrile rubber on the mill for 5 to 8 times;

[0047] c) Add zinc oxide, stearic acid, silicon carbide, boron phenolic resin, decabromodiphenyl ether, and antimony trioxide in sequence, and the roll distance is 3 mm; cut glue and roll 3 times;

[0048] d) Add white carbon black and dioctyl sebacate in 3 times, the roller distance is 3mm; cut glue and roll 3 times;

[0049] e) Add aramid chopped fiber in 5 times, cut glue and roll 3 times, the roller distance is 3mm;

[0050] f) Thin pass 2 times, the roller distance is 0.3mm, and then cut the glue and roll 2 times at the roller distance 3mm; repeat this step 3 times;

[0051] g) Dicumyl peroxide is added, the roller distance is ...

example 2

[0060] (1) Weigh each component of the formula

[0061] Weigh the ingredients of the formula according to the table below.

[0062]

[0063]

[0064] (2) heat insulation layer refining

[0065]a) Dry the weighed aramid chopped fiber and white carbon black at 80°C for 1 hour;

[0066] b) Thinly pass the nitrile rubber on the mill for 5 to 8 times;

[0067] c) Add zinc oxide, stearic acid, silicon carbide, boron phenolic resin, decabromodiphenyl ether, and antimony trioxide in sequence, and the roll distance is 3 mm; cut glue and roll 3 times;

[0068] d) Add white carbon black and dioctyl sebacate in 3 times, the roller distance is 3mm; cut glue and roll 3 times;

[0069] e) Add aramid chopped fiber in 5 times, cut glue and roll 3 times, the roller distance is 3mm;

[0070] f) Thin pass 2 times, the roller distance is 0.3mm, and then cut the glue and roll 2 times at the roller distance 3mm; repeat this step 3 times;

[0071] g) Dicumyl peroxide is added, the roller d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com