MOFs derivative Co-Ni-B-P composite material and preparation method and application thereof

A technology of co-ni-b-p and composite materials, applied in nanotechnology for materials and surface science, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc. The low utilization rate of metal active sites can achieve the effects of shortening the ion transmission distance, excellent material stability, and green preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A preparation method of MOFs derivative Co-Ni-B-P, comprising the following steps:

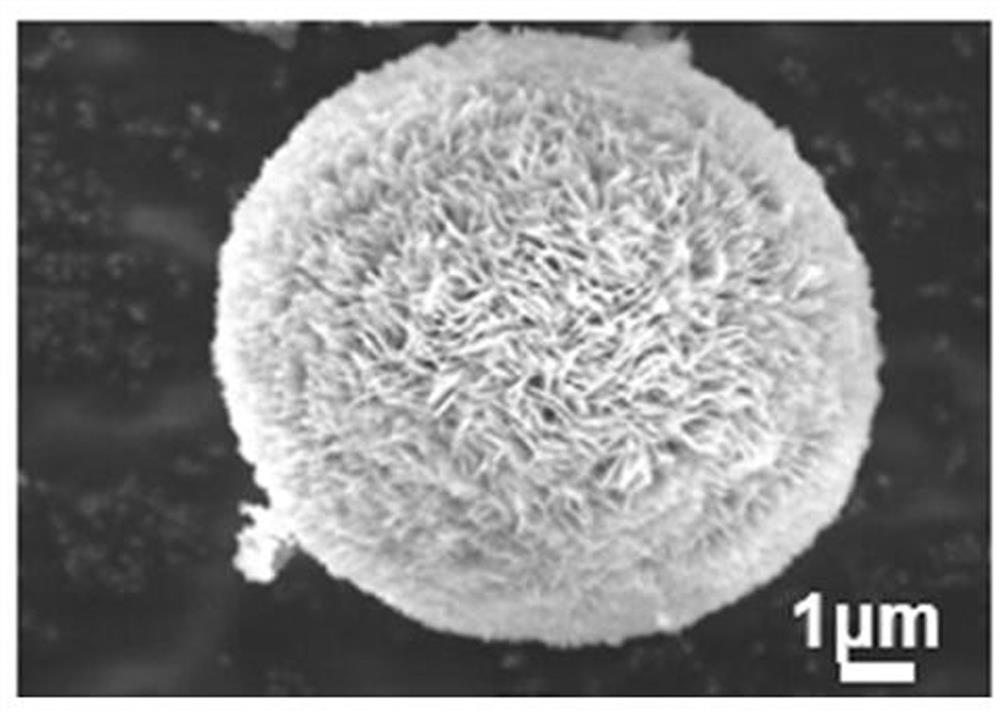

[0063] Step 1) Preparation of Co-Ni-MOF material, weigh 0.5667 g cobalt acetate and 0.5764 g nickel acetate dissolved in 32 ml N,N-dimethylacetamide to form a pink A solution, then weigh 0.562 g 1,2,3,4-butane tetracarboxylic acid is dissolved in 24ml of N,N-dimethylacetamide to form a B solution, and then the B solution is added to the A solution for solvothermal reaction, the temperature of the solvothermal reaction The temperature is 160 ℃, and the solvothermal reaction time is 12 h. After the reaction is completed, the Co-Ni-MOF material, referred to as Co-Ni-MOF, can be obtained by washing and drying;

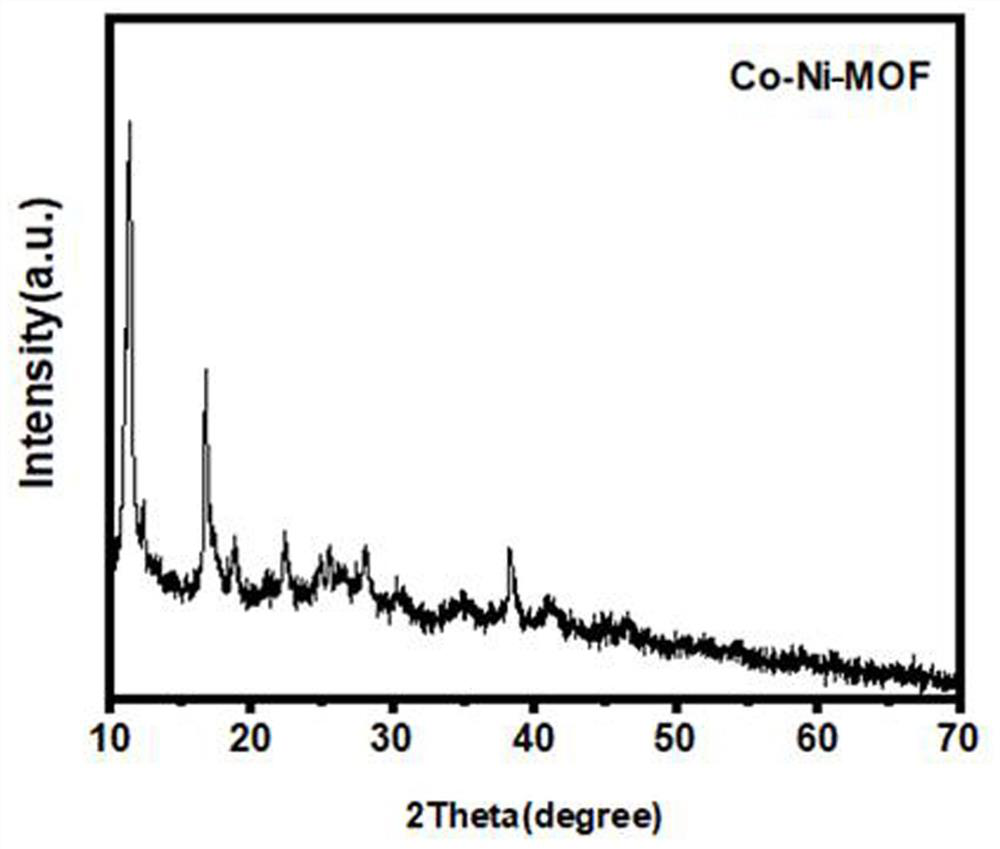

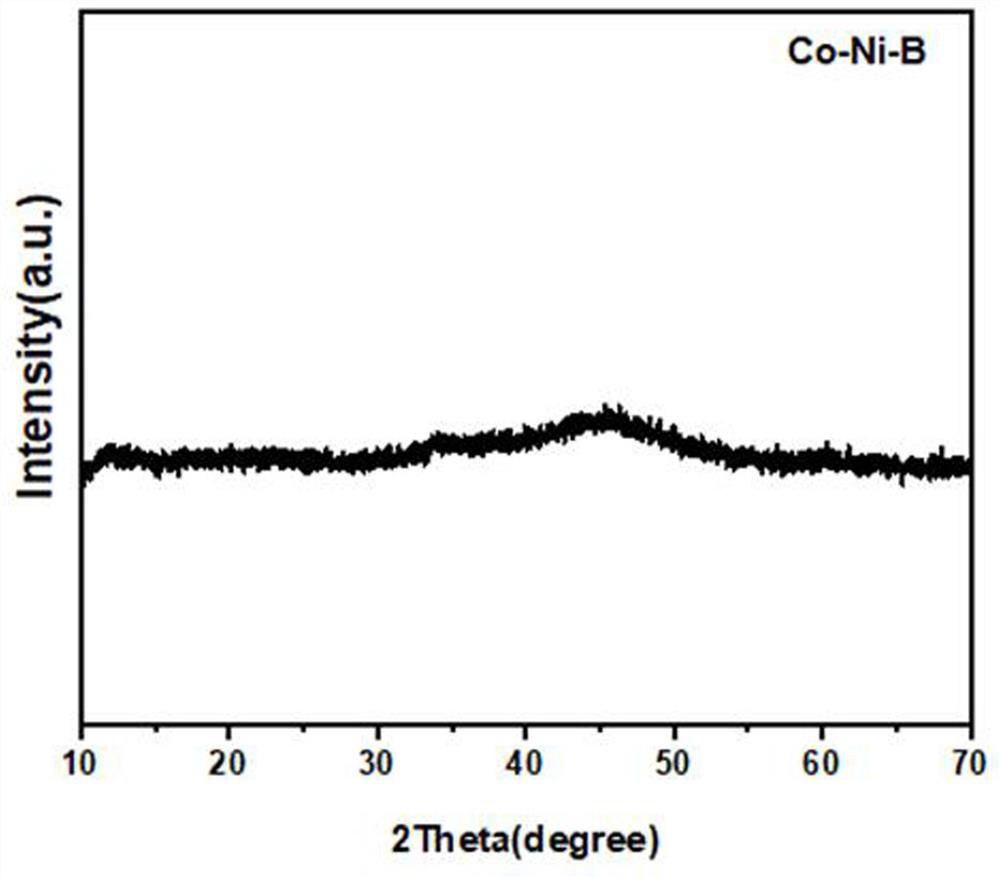

[0064] In order to prove that the material composition of the Co-Ni-MOF material obtained in step 1 is detected by X-ray diffraction, the results are as follows figure 1 As shown, the peak shape is compared with the diffraction peak of Co-Ni-MOF, and there is a sharper peak, indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com