Counter electrode of nickel iron selenide dye-sensitized solar cell

A technology for solar cells and dye sensitization, which is applied in the field of counter electrodes of iron-nickel selenide dye-sensitized solar cells to achieve the effects of superior catalytic performance, enhanced contact force, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 12mL of deionized water, put it in a beaker with a volume of 50mL, and add 0.025 mmol NiCl 2 ·6H 2 O, 0.05 mmol FeCl 3 ·6H 2 O and 0.1 mmol Se, 10 mL NH was added dropwise with constant stirring 3 ·H 2 O, 3mL N 2 H 4 ·H 2 O, after continuing to stir for 15min, transfer the solution in the beaker to the autoclave, place a piece of 1.5×3cm ITO glass conductive side down and place it at an angle of 45° with the inner wall of the reactor, the reactor is covered with a shell and placed in In a 120°C oven for 12 hours, the reaction was carried out at a constant temperature, cooled to room temperature naturally, taken out, rinsed with deionized water and ethanol for several times, and then air-dried to obtain a black iron-nickel-selenide counter electrode.

[0017] The remaining black precipitate in the kettle was centrifuged, washed three times with deionized water and ethanol, and freeze-dried for subsequent characterization.

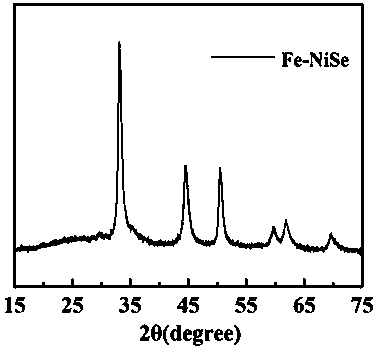

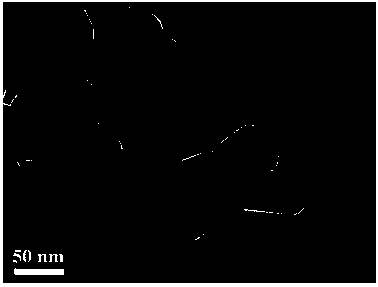

[0018] figure 1 It is the XRD pat...

Embodiment 2

[0022] Take 10mL of deionized water, put it in a beaker with a volume of 50mL, and add 0.025 mmol NiCl 2 ·6H 2 O, 0.05 mmol FeCl 3 ·6H 2 O and 0.1 mmol Se, 10 mL NH was added dropwise with constant stirring 3 ·H 2 O, 2mL N 2 H 4 ·H 2 O, after continuing to stir for 15min, transfer the solution in the beaker to the autoclave, place a piece of 1.5×3cm ITO glass conductive side down and place it at an angle of 45° with the inner wall of the reactor, the reactor is covered with a shell and placed in In a 120°C oven for 12 hours, the reaction was carried out at a constant temperature, cooled to room temperature naturally, taken out, rinsed with deionized water and ethanol for several times, and then air-dried to obtain a black iron-nickel-selenide counter electrode.

Embodiment 3

[0024] Take 15mL of deionized water, put it in a beaker with a volume of 50mL, and add 0.025 mmol NiCl 2 ·6H 2 O, 0.05 mmol FeCl 3 ·6H 2 O and 0.1 mmol Se, 10 mL NH was added dropwise with constant stirring 3 ·H 2 O, 5mL N 2 H 4 ·H 2 O, after continuing to stir for 15min, transfer the solution in the beaker to the autoclave, place a piece of 1.5×3cm ITO glass conductive side down and place it at an angle of 45° with the inner wall of the reactor, the reactor is covered with a shell and placed in In a 100°C oven for 12 hours, the reaction was carried out at a constant temperature, cooled to room temperature naturally, washed several times with deionized water and ethanol, and then air-dried to obtain a black iron-nickel selenide counter electrode.

[0025] with commercial TiO 2 The slurry was used as a photoanode, and N719 was used as a sensitizer, and was assembled with the iron-nickel selenide counter electrode prepared in Example 1 to form a sandwich structure batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com