Automatic lifting and shock absorbing self-balancing mechanism for spray rod application machine

An automatic lifting and spraying machine technology, which is applied to the application, device for catching or killing insects, animal husbandry, etc., can solve the problems of affecting the spraying effect of the spraying machine, affecting the stability of the spray bar, and poor balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

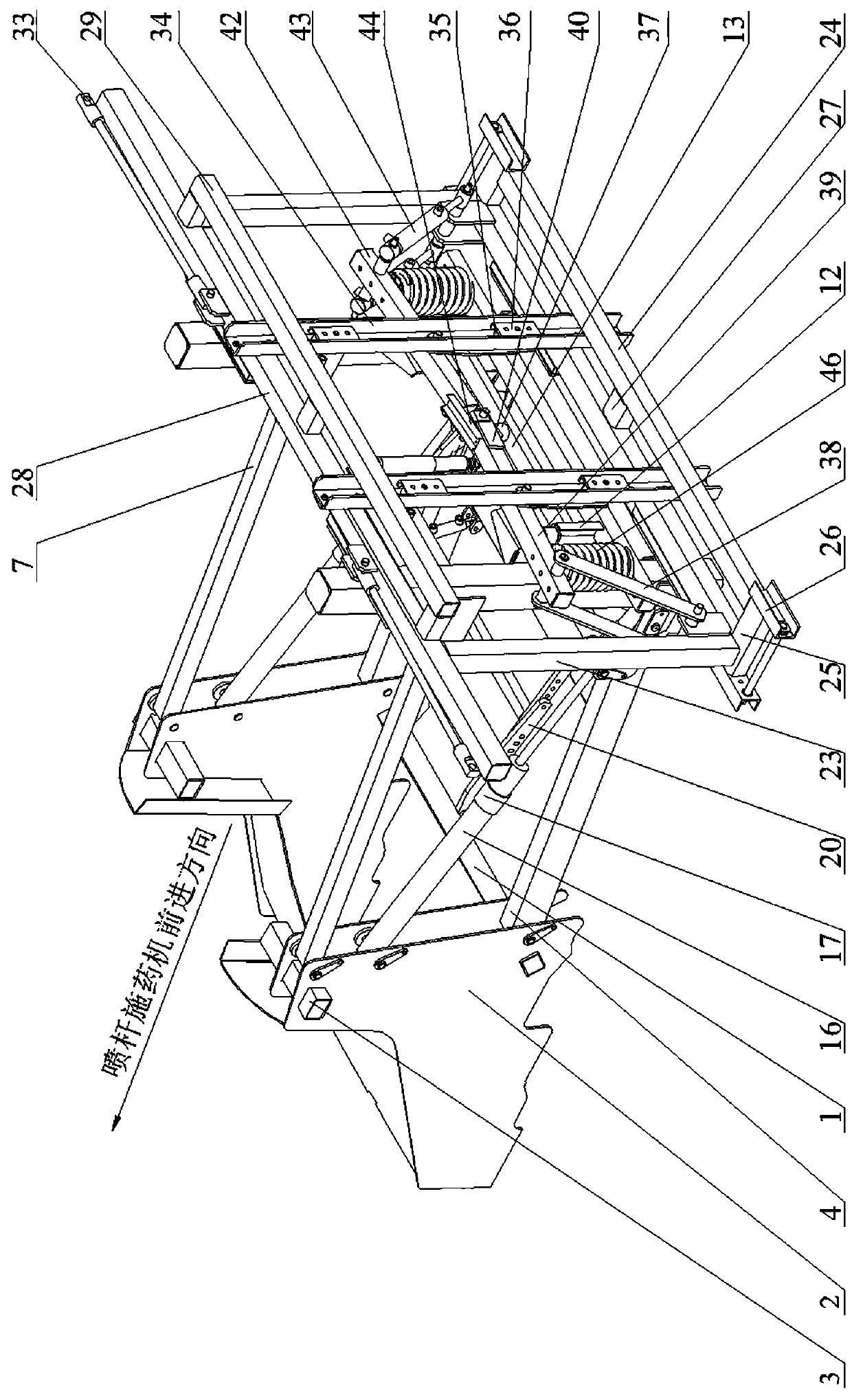

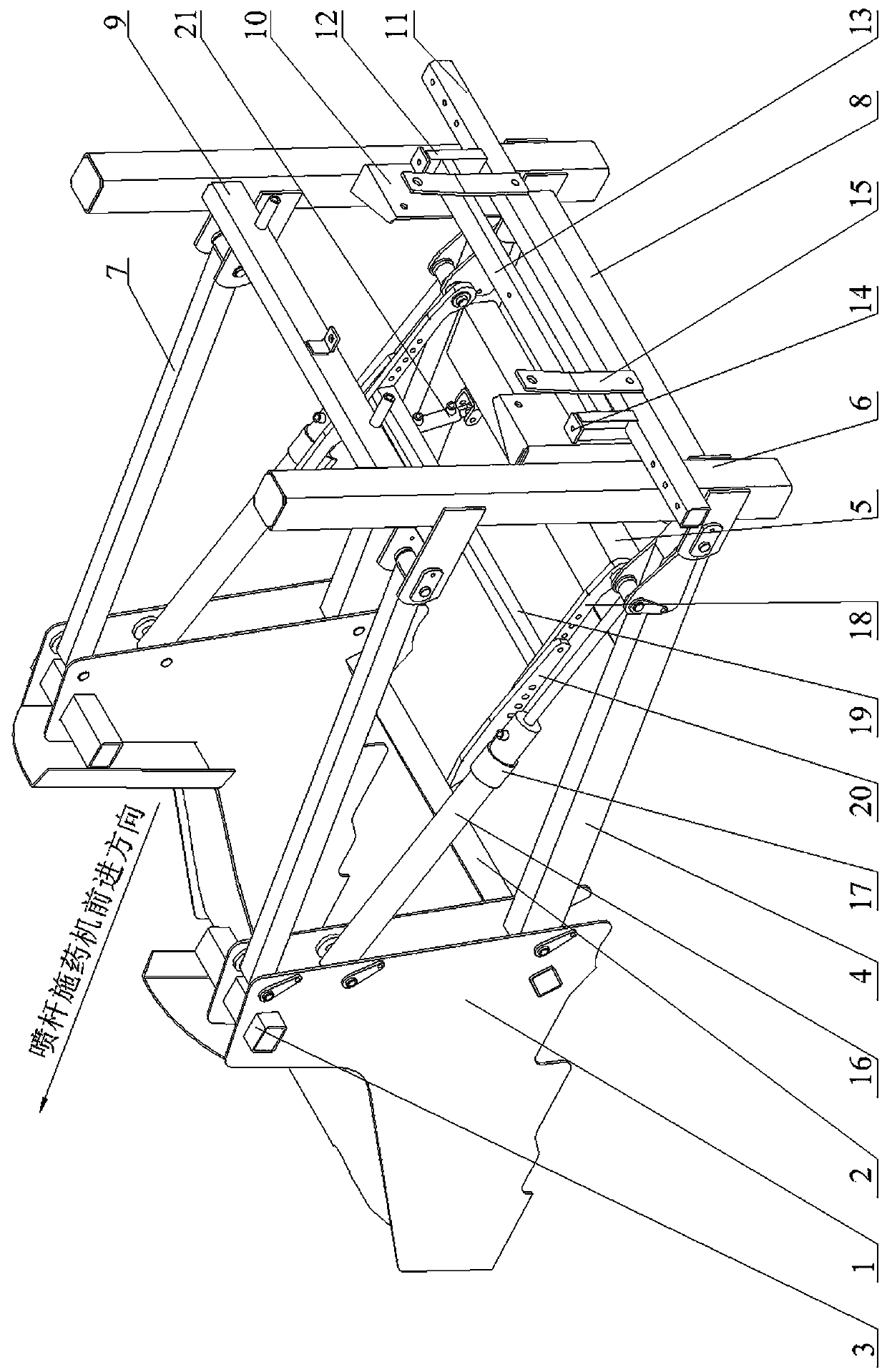

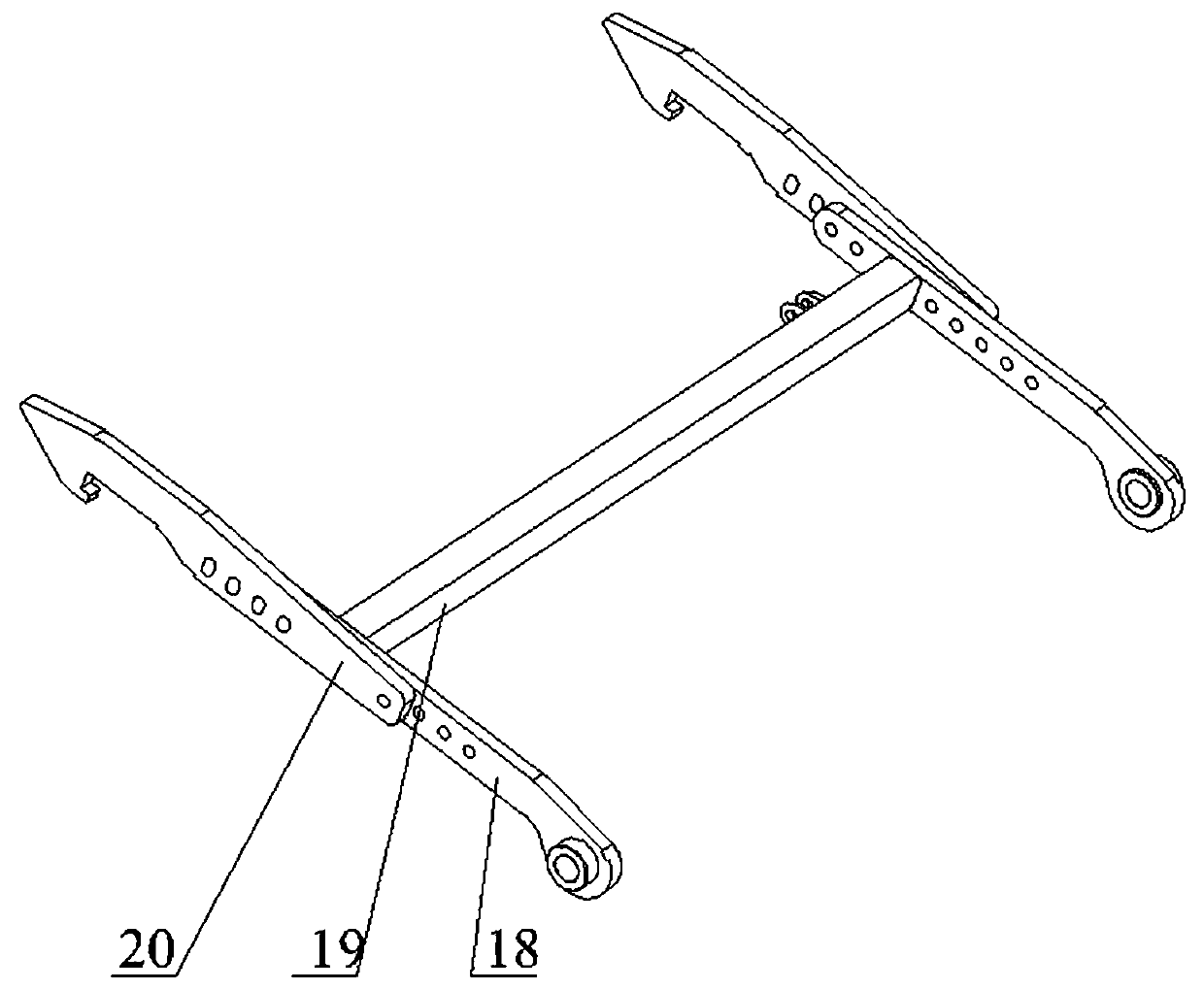

[0019] 1. Vertical plate 2, support rod Ⅰ 3, support rod Ⅱ 4, connecting rod Ⅰ 5, horizontal connecting rod Ⅰ 6, supporting column 7, connecting rod Ⅱ 8, beam Ⅰ 9, beam Ⅱ 10, fixed bent plate 11, beam Ⅲ 12. Longitudinal connecting frame 13, beam IV 14, end plate 15, connecting bent plate 16, hydraulic cylinder I 17, hook plate 18, adjusting plate I 19, horizontal connecting rod II 20, adjusting plate II 21, hydraulic cylinder II 22, fixed Plate 23, connecting support rod 24, square tube I 25, square tube II 26, connecting groove 27, connecting tube 28, square tube III 29, square tube IV 30, square tube V 31, backing plate 32, pad 33, connection Tie rod 34, vertical bending plate 35, damping block 36, buckle plate 37, buffer block 38, pull plate 39, connecting rod I 40, lap plate 41, rotating shaft 42, connecting rod II 43, hydraulic cylinder III 44, single hole Connecting block 45, fixed ring 46, stage clip 47, connecting post 48, hinge shaft 49, damper.

[0020] exist Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com