Drill bit

A drilling stand and sliding column technology, which is used in repairing drilling, drilling tool accessories, boring/drilling, etc., can solve problems such as low precision and inability to detect errors in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

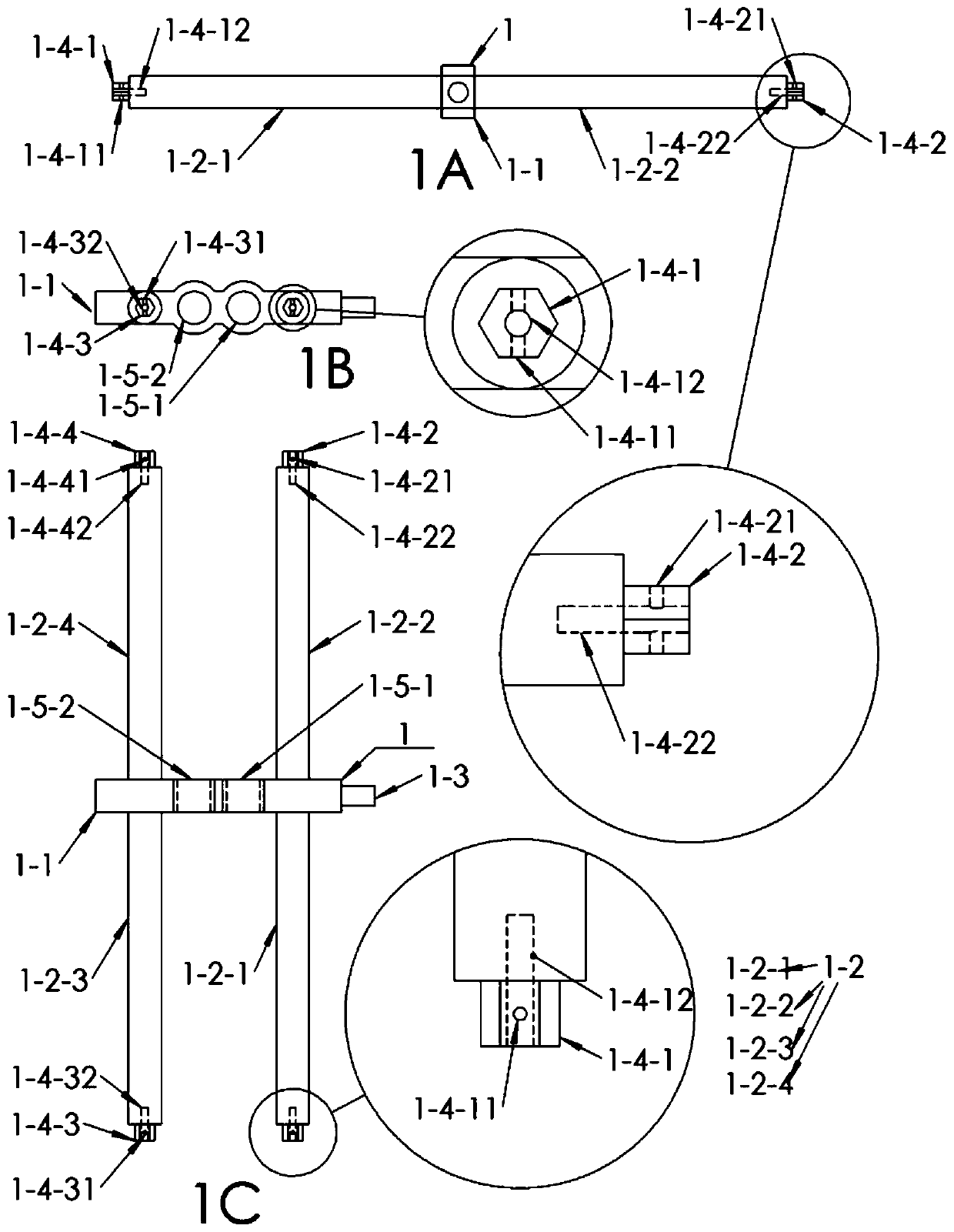

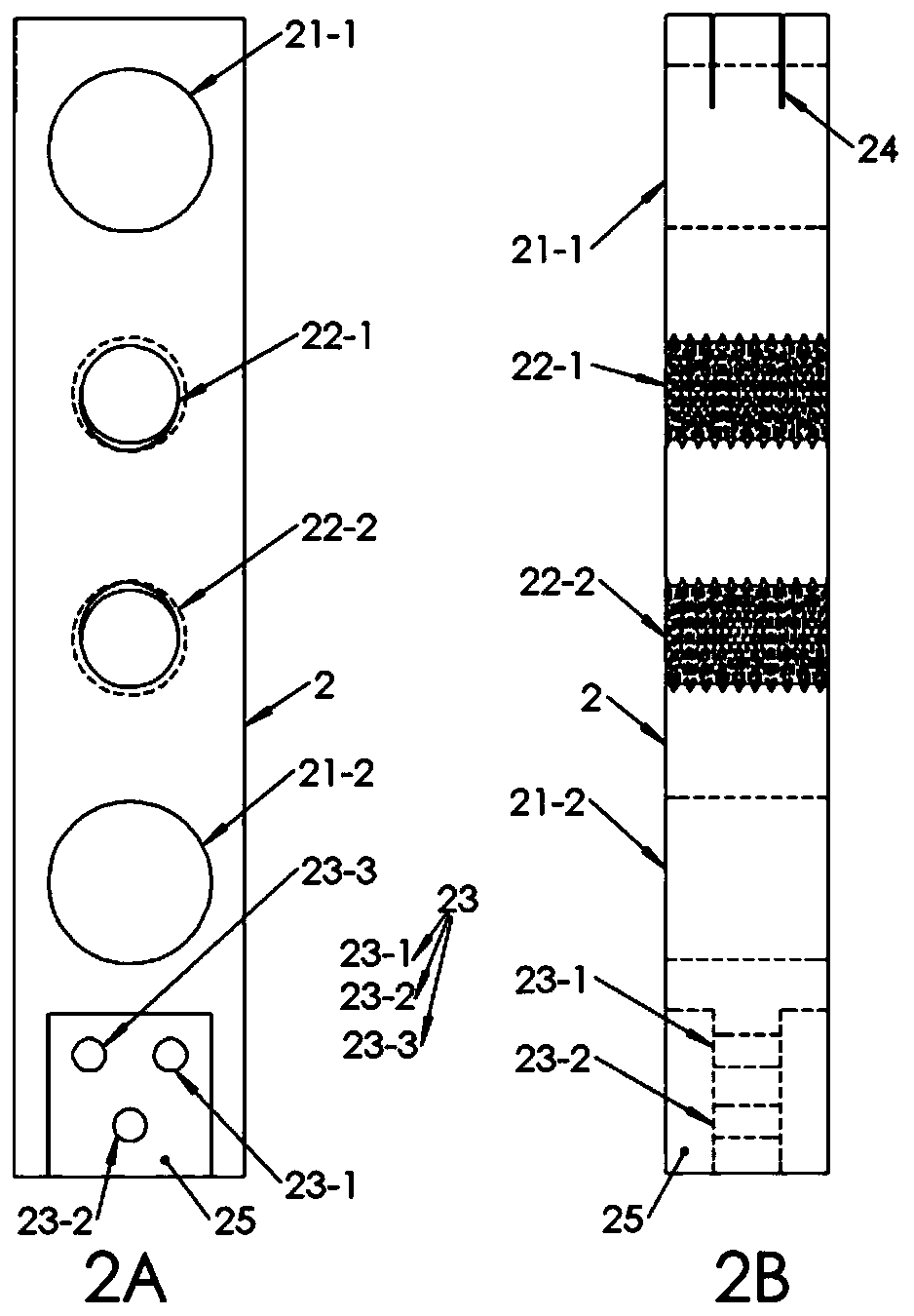

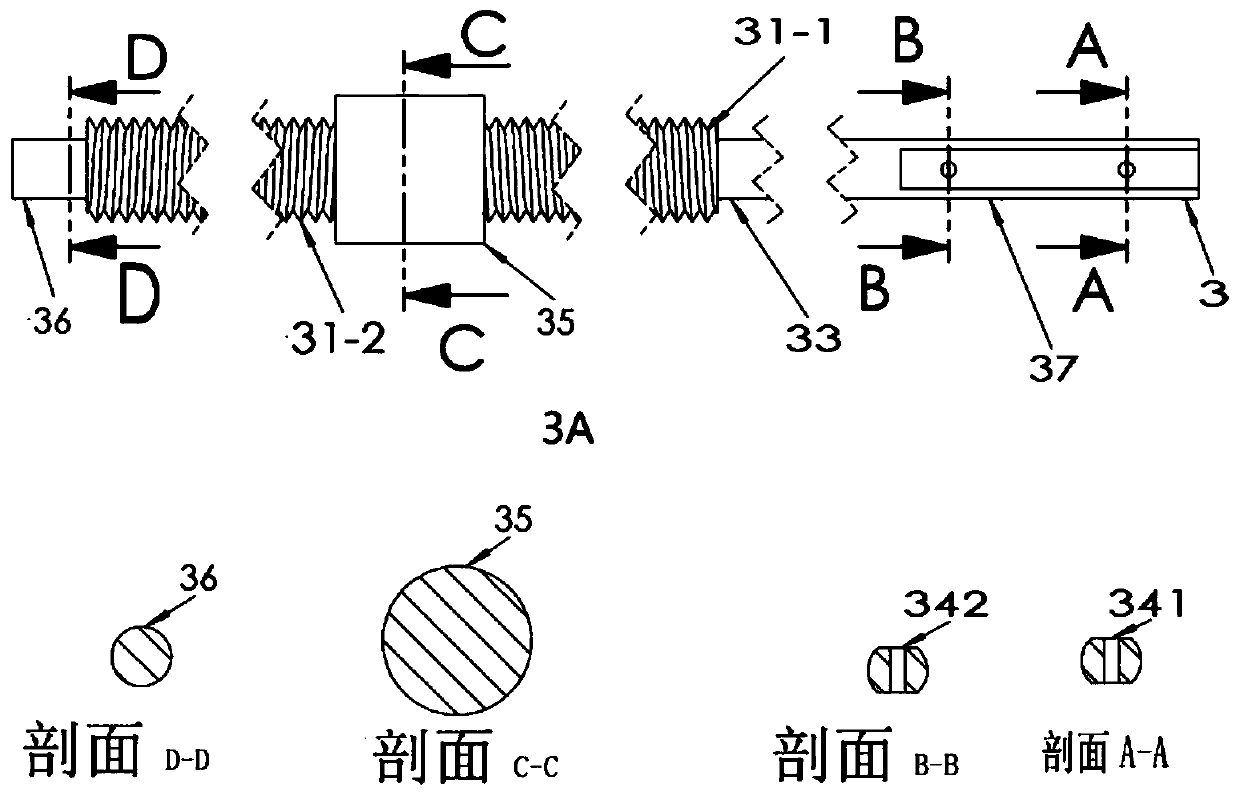

[0139] Embodiment 1, an adjustable hole opener is characterized in that: it includes a drill stand (1), a knife rest (2), a screw rod (3), a baffle plate (4), a guard plate (5), a positioning gear (6) ), buckle (7), blade (8), spring (9), button (10), scale plate (14), buckle plate (69);

[0140] The drilling frame (1) includes a support rod (1-1), a slide rail (1-2), a connecting column (1-3), a first screw hole (1-5-1), a second screw hole (1-5 -2); in the drill stand (1): the slide rail (1-2) consists of the first sliding column (1-2-1), the second sliding column (1-2-2), the third sliding column (1- 2-3), the fourth sliding column (1-2-4) constitutes;

[0141] In the drill stand (1): the first screw hole (1-5-1) and the second screw hole (1-5-2) are located on the support rod (1-1);

[0142] In the drill stand (1): the first sliding column (1-2-1), the second sliding column (1-2-2), the third sliding column (1-2-3), the fourth sliding column (1- 2-4), all four have a fi...

Embodiment 2

[0252] Embodiment 2, based on Embodiment 1, further: in the drill frame (1): the second end (1-4-1) of the first sliding post (1-2-1) has an eleventh installation hole ( 1-4-11); the eleventh mounting hole (1-4-11), the first sliding column (1-2-1), the axes of the two are perpendicular.

Embodiment 3

[0253] Embodiment 3, based on Embodiment 1, further: in the drill frame (1): the second end (1-4-2) of the second strut (1-2-2) has a twenty-first installation hole (1-4-21); the twenty-first mounting hole (1-4-21), the second sliding column (1-2-2), the two axes are vertical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com