Intelligent removal system and method for steel coil bundling belt

A steel coil and intelligent technology, applied in the application field of intelligent equipment in intelligent factories, can solve the problems of high labor intensity and high danger in the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

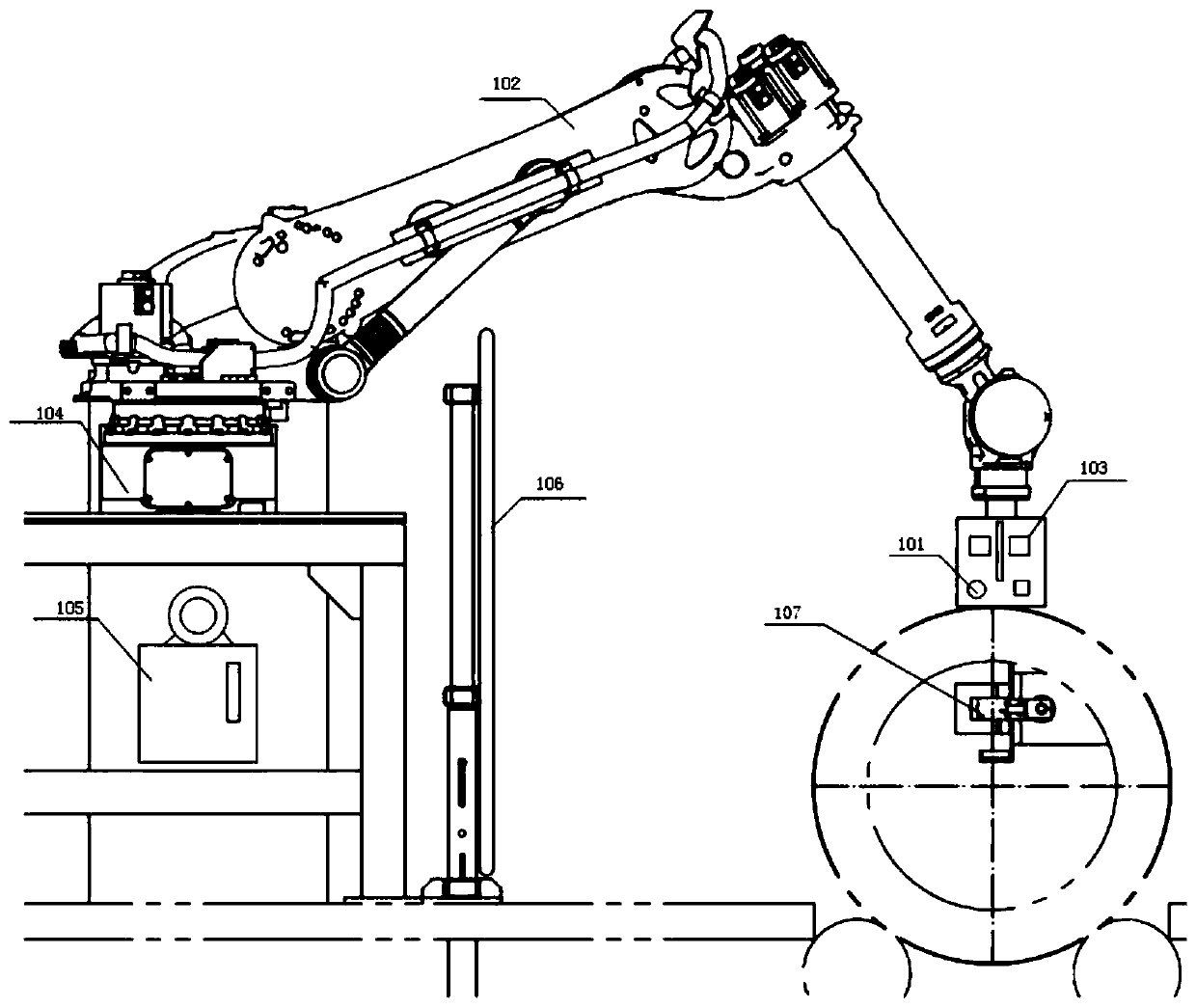

[0027] A set of steel coil strapping intelligent removal system proposed by the present invention uses a mechanical arm instead of manual detection and judgment to automatically realize the cutting and collection processing of the steel coil strapping at the stripping station in the production process.

[0028] An intelligent removal system for steel coil strapping includes a strap head position detection module 101, a strap head direction detection device 107, a mechanical arm 102, a machine head 103, a control unit 104, a hydraulic station 105, a strap collection device and a conveying device, and a safety protection device 106 . The machine head 103 is connected to the mechanical arm 102 through a connecting flange.

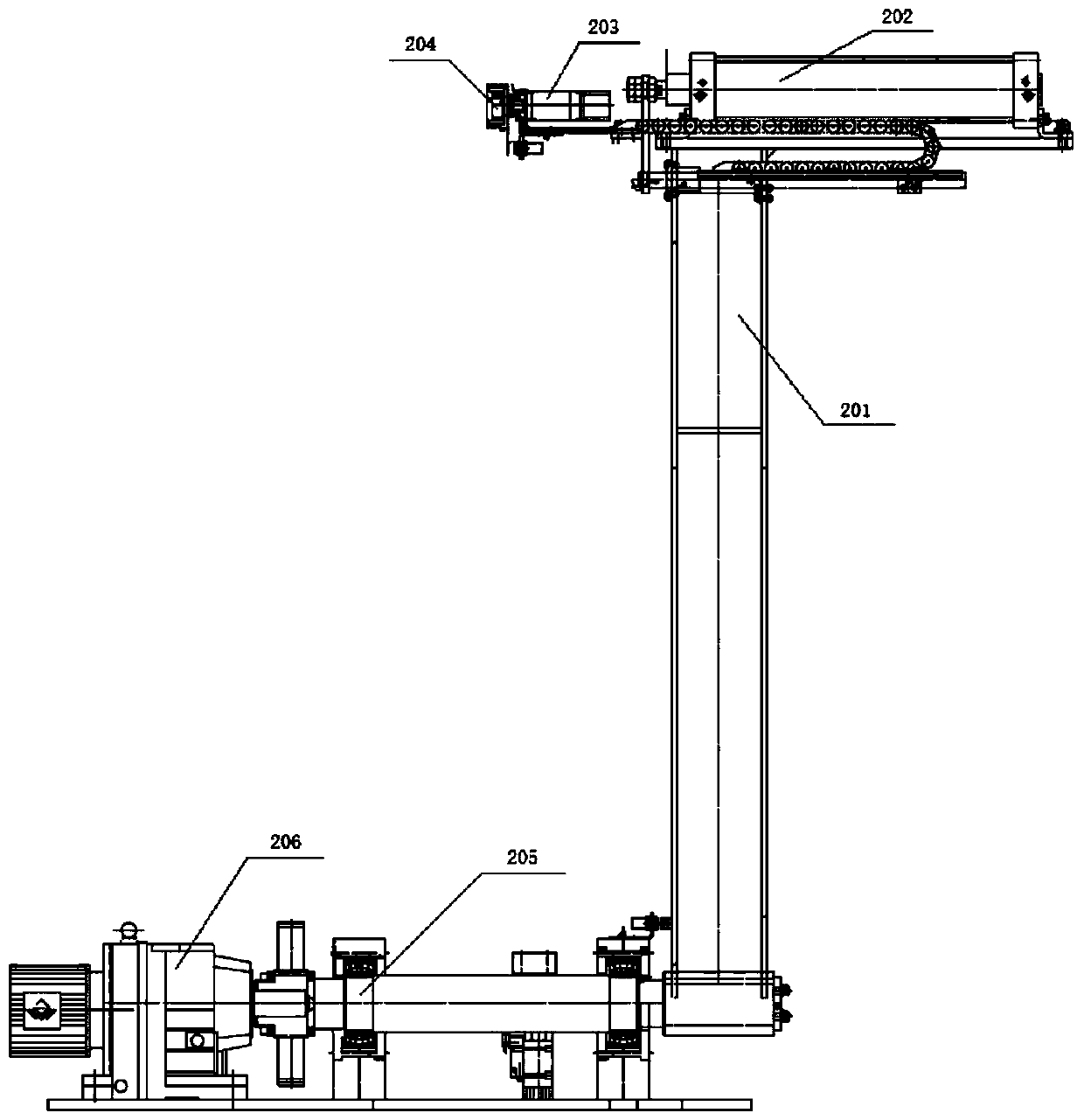

[0029] The head direction detection device includes seven parts including swing arm mechanism 201, telescopic cylinder 202, first rotating motor 203 and second rotating motor 206, laser distance sensor 204, drive shaft 205 and control system. The belt head di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com