A thick gauge high wear resistance steel plate and its manufacturing method

A technology with high wear resistance and manufacturing method, applied in the field of alloy steel, can solve the problems of poor performance uniformity, low production efficiency and high production cost, and achieve the effects of good plate shape, improved plasticity and improved hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

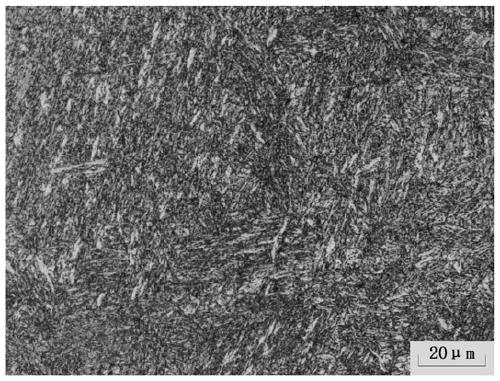

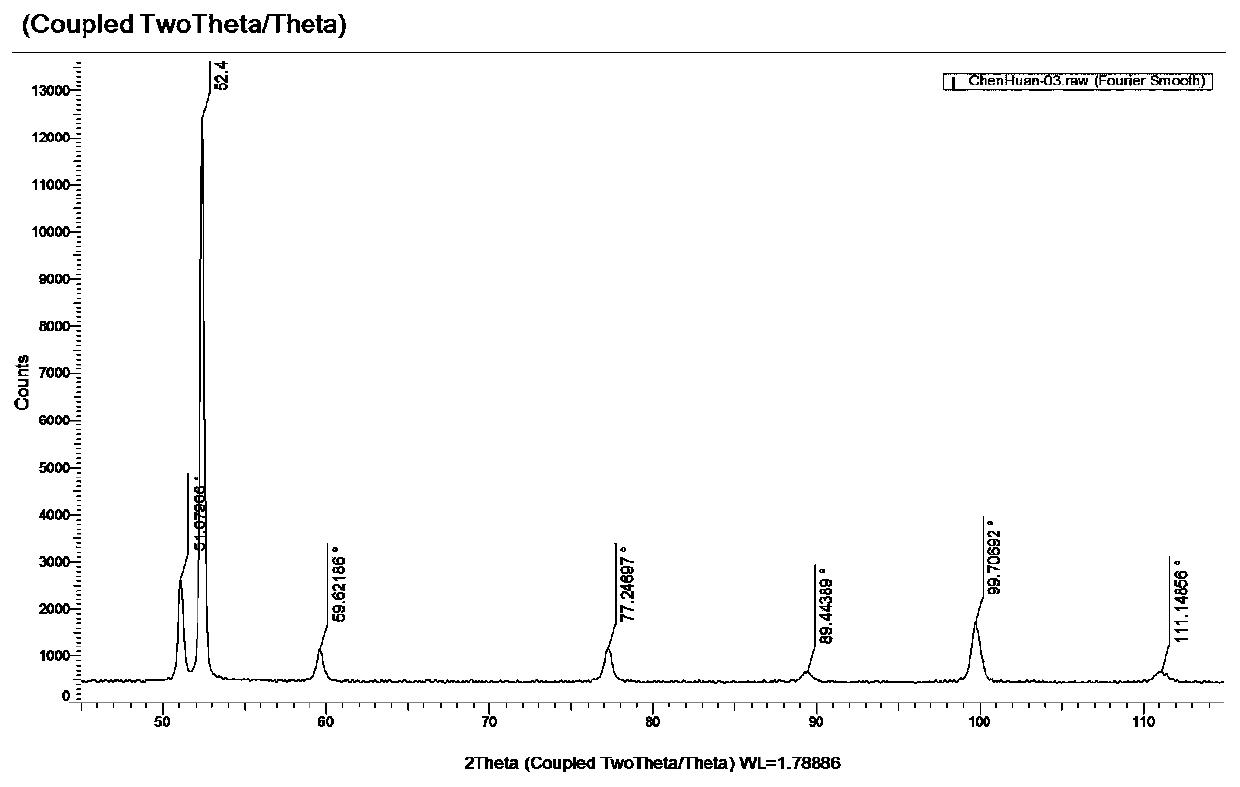

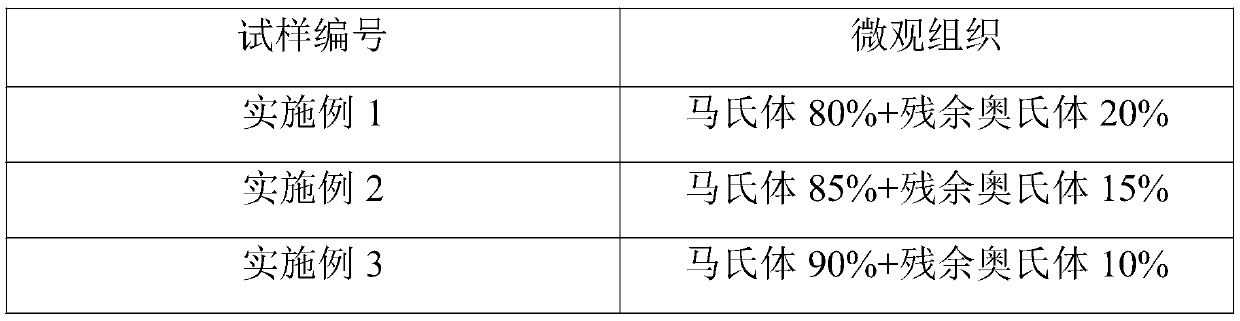

Embodiment 1

[0043] The chemical composition (mass percentage%) of the thick gauge high wear resistance steel plate of this embodiment is: C: 0.12; Si: 1.23; Mn: 3.9; Cr: 0.82; Ni: 0.55; Mo: 0.31; S: 0.005; : 0.005; V: 0.05; the balance is Fe and unavoidable impurities.

[0044] The specific steps and process parameters are as follows:

[0045] Step 1: using a converter to smelt the raw materials of the steel plate, LF refining, RH refining, and slab continuous casting (350mm continuous casting slab);

[0046] Step 2: Heat the continuous casting slab in a heating furnace to a temperature of 1180°C, hold for 6 hours, and roll it with a medium-thick plate rolling mill, with 5 passes for rough rolling, 9 passes for finish rolling, and 9 passes for finish rolling. The final rolling temperature is 900°C, and the steel plate thickness is 130mm;

[0047] Step 3: After the rolled steel plate is air-cooled to 190°C, it is immediately placed in a heating furnace and heated to a distribution temper...

Embodiment 2

[0049] The chemical composition (% by mass) of the thick gauge high wear resistance steel plate of this embodiment is: C: 0.25; Si: 1.29; Mn: 3.92; Cr: 0.91; Ni: 1.51; Mo: 0.32; S: 0.015; P : 0.015; V: 0.18; the balance is Fe and unavoidable impurities.

[0050] The specific steps and process parameters are as follows:

[0051] Step 1: using a converter to smelt the raw materials of the steel plate, LF refining, and continuous casting of slabs (300mm continuous casting slab);

[0052] Step 2: Heat the continuous casting slab in a heating furnace to a temperature of 1180°C, hold for 8 hours, and roll it with a medium-thick plate rolling mill, with 5 passes for rough rolling, 11 passes for finish rolling, and 11 passes for finish rolling. The final rolling temperature is 850°C, and the thickness of the steel plate is 45mm;

[0053] Step 3: After the rolled steel plate is air-cooled to 200°C, it is immediately put into a heating furnace and heated to a distribution temperature ...

Embodiment 3

[0055] The chemical composition (% by mass) of the thick gauge high wear resistance steel plate of this embodiment is: C: 0.32; Si: 1.29; Mn: 4.62; Cr: 0.51; Ni: 0.51; Mo: 0.32; S: 0.015; : 0.015; V: 0.20; the balance is Fe and unavoidable impurities.

[0056] The specific steps and process parameters are as follows:

[0057] Step 1: use a converter to smelt the raw materials of the steel plate, LF refining, and die casting (750mm flat ingot);

[0058] Step 2: Heat the steel ingot in a heating furnace to a temperature of 1220°C, hold for 8 hours, and roll it with a medium-thick plate rolling mill, with 5 passes for rough rolling, 7 passes for finish rolling, and finally The rolling temperature is 1000℃, and the steel plate thickness is 395mm;

[0059] Step 3: After the rolled steel plate is air-cooled to 200°C, it is immediately placed in a heating furnace and heated to a distribution temperature of 300°C for distribution. The distribution time is 120 minutes. After the dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com