Bypass flow guiding sieve tube

A flow screen and base pipe technology, applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of low efficiency of pressure test operation, difficult disassembly and assembly, and high time-consuming operation, and achieve simplified gravel packing pipe Column, easy to operate, safe and reliable, and improve the effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content of the present invention, the present invention will be further described in conjunction with the accompanying drawings.

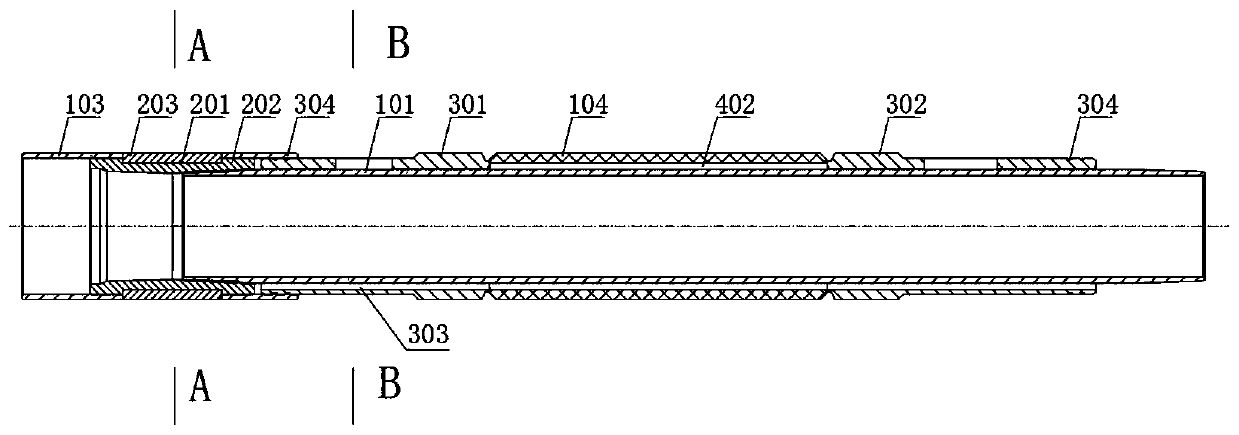

[0019] refer to figure 1 , the present invention provides a bypass diversion screen, including a base pipe 101, the two ends of the base pipe 101 are provided with threads, the upper end of which is connected with the tie-back sealing cylinder 103 through a fastening mechanism 201, and the outside of the base pipe 101 A screen assembly 104 is set therein, the upper end of the screen assembly 104 is connected with an upper tie-back sealing joint 301 , and the lower end is connected with a lower tie-back sealing joint 302 .

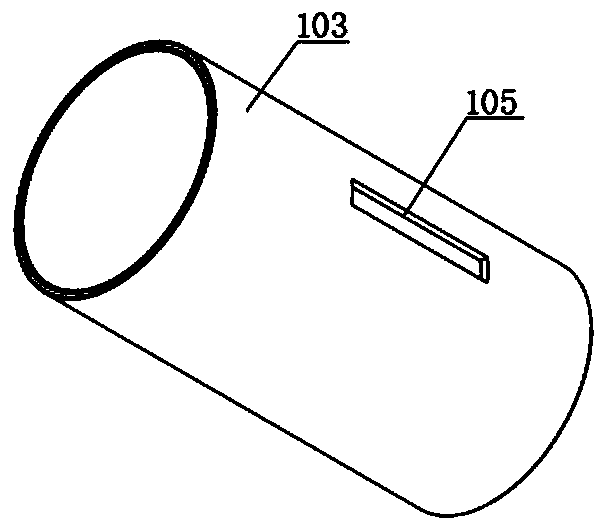

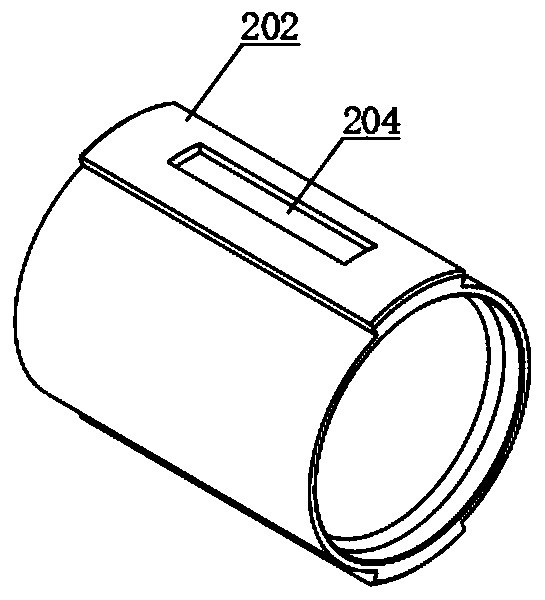

[0020] refer to Figure 1-Figure 4 , two through-holes 105 are arranged symmetrically on the cylinder wall of the tie-back seal cylinder 103; the fastening mechanism 201 is composed of a bypass collar 202 and a flat key 203; the bypass collar 202 is symmetrically distributed with two T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com