Argon system load changing method for large oxygen generator unit

A variable load and unit technology, applied in refrigeration and liquefaction, liquefaction, solidification and other directions, can solve the problems of wasted steam, energy waste, environmental noise pollution, etc., and achieve the effect of reducing the discharge of liquid argon and eliminating energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

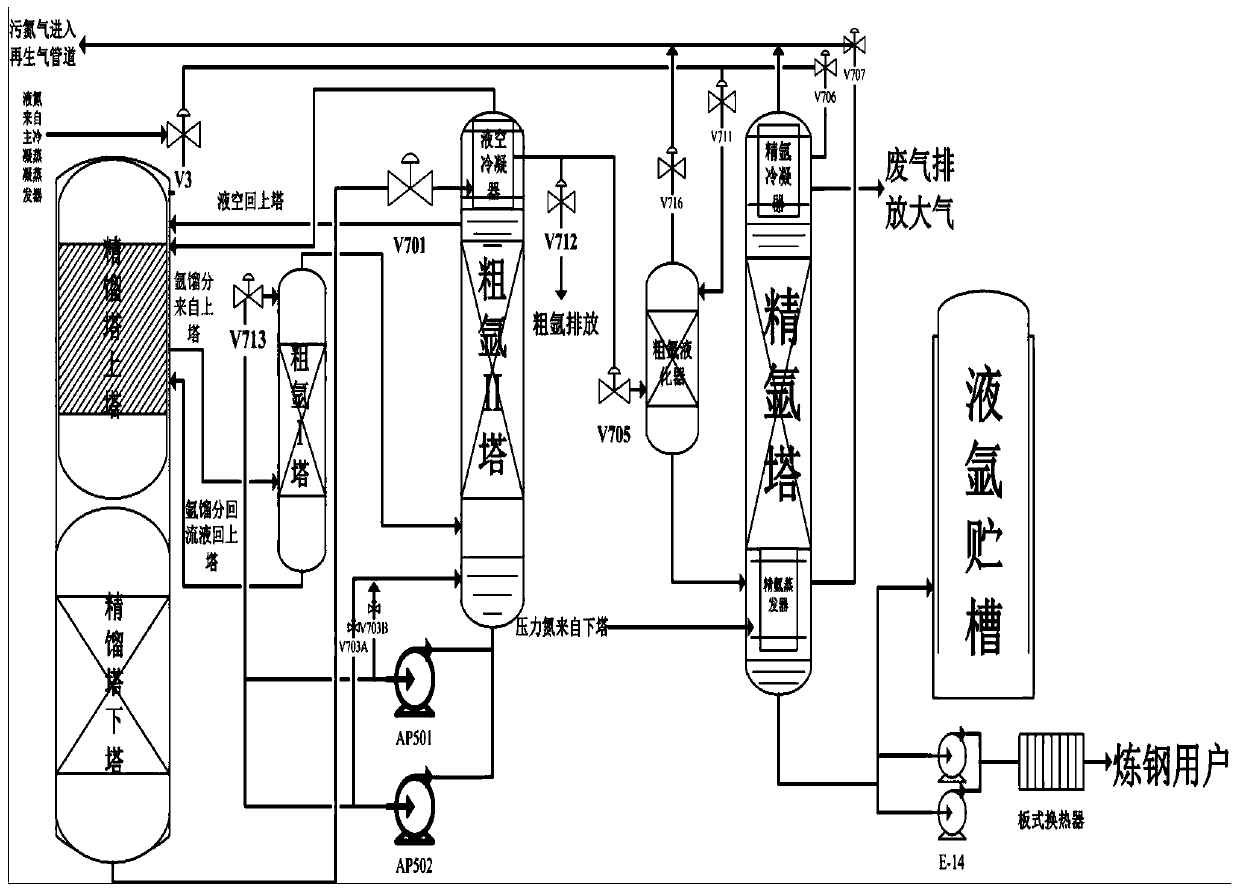

Image

Examples

Embodiment 1

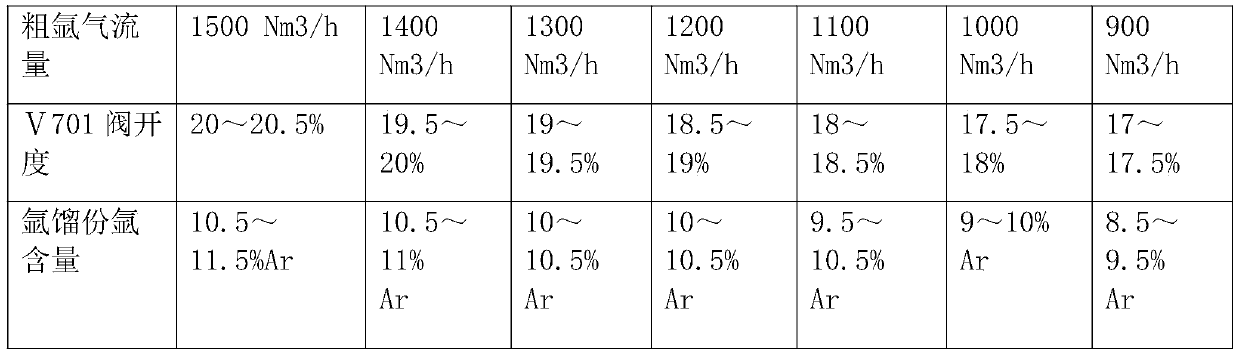

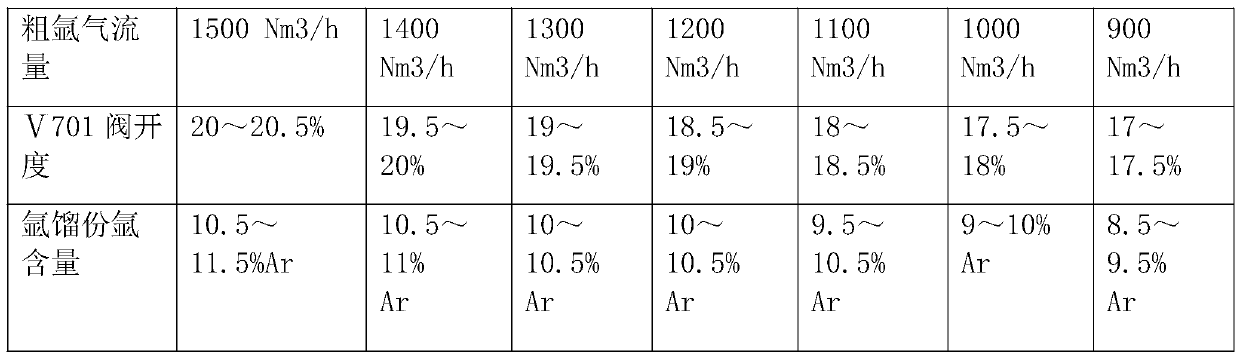

[0024] The method for changing the load of the argon system of a large-scale oxygen generator provided by the present invention, after the actual operation and adjustment, concludes that the load changing operation of the argon system can adopt the following two effective operation methods:

[0025] 1) The argon production increase operation method can increase the argon production from the design value of 1500Nm3 / h to 1700Nm3 / h. When the argon supply is tight, the pressure of the pipeline network can be supplemented and the liquid argon product can be increased.

[0026] 2) The argon production reduction operation method can reduce the argon production from 1700Nm3 / h to 900Nm3 / h to reduce the production of liquid argon to reduce waste and save energy.

[0027] However, in the process of changing the load, it will have a certain impact on the main tower and the argon system. For example, nitrogen plugs in the argon system will be encountered during production increase and decr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com