Cam mechanism inside internal combustion engine with piston doing circular motion

A cam mechanism and circular motion technology, applied in the fields of internal combustion engines, gasoline engines, and natural gas engines, can solve the problems of energy consumption of compressed mixed gas, small piston working stroke, and waste of working energy, so as to reduce energy consumption, increase working stroke, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

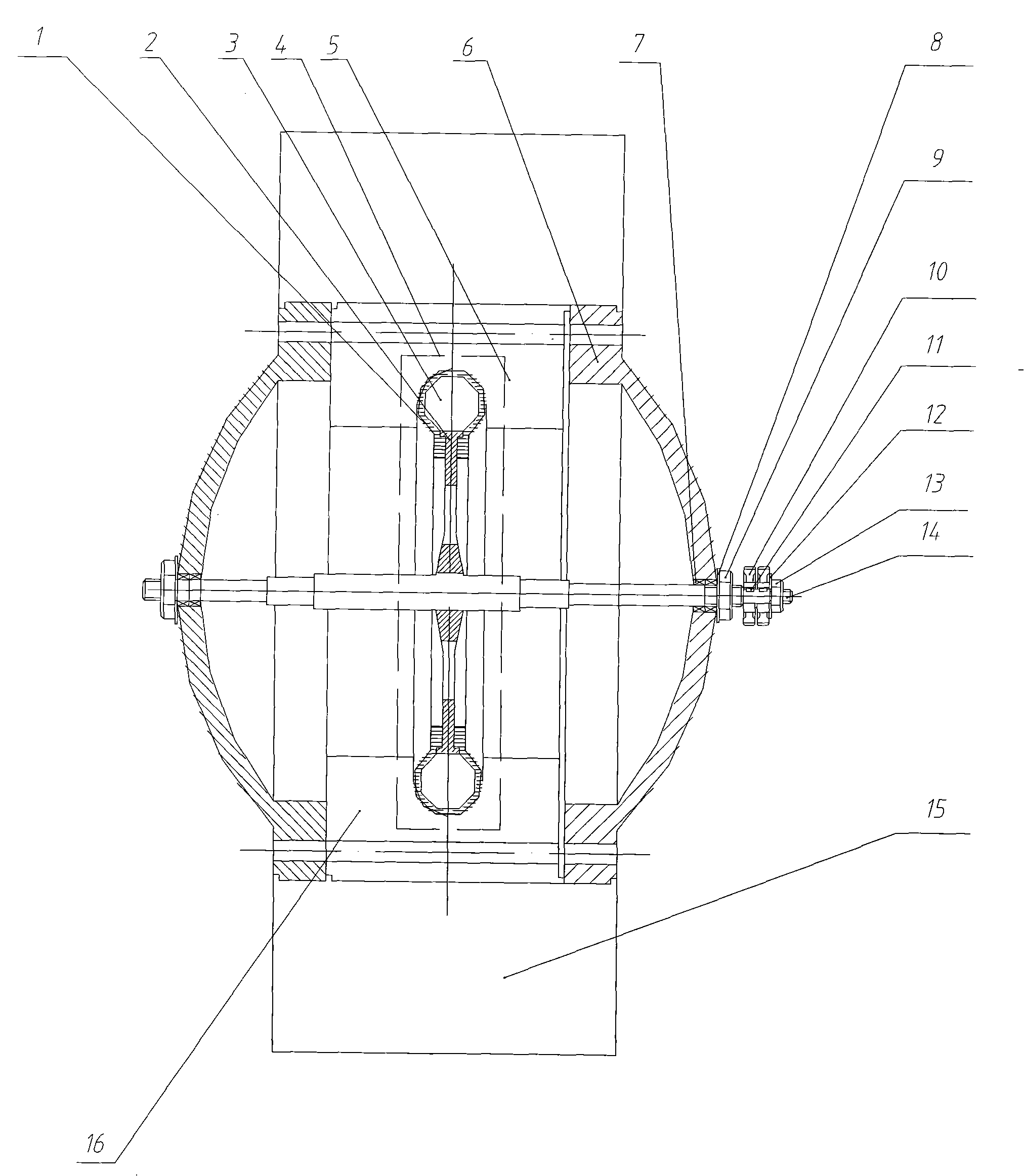

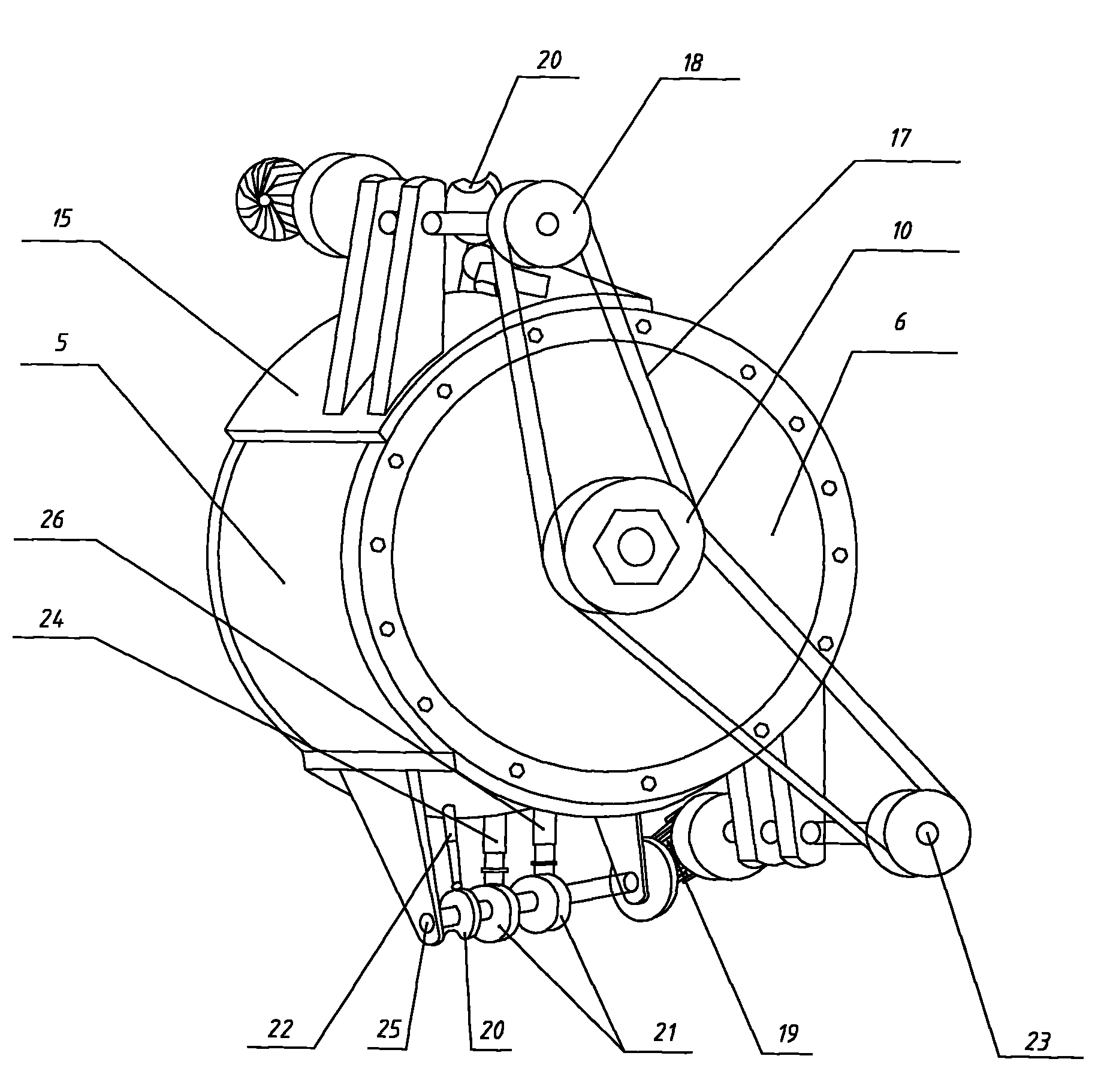

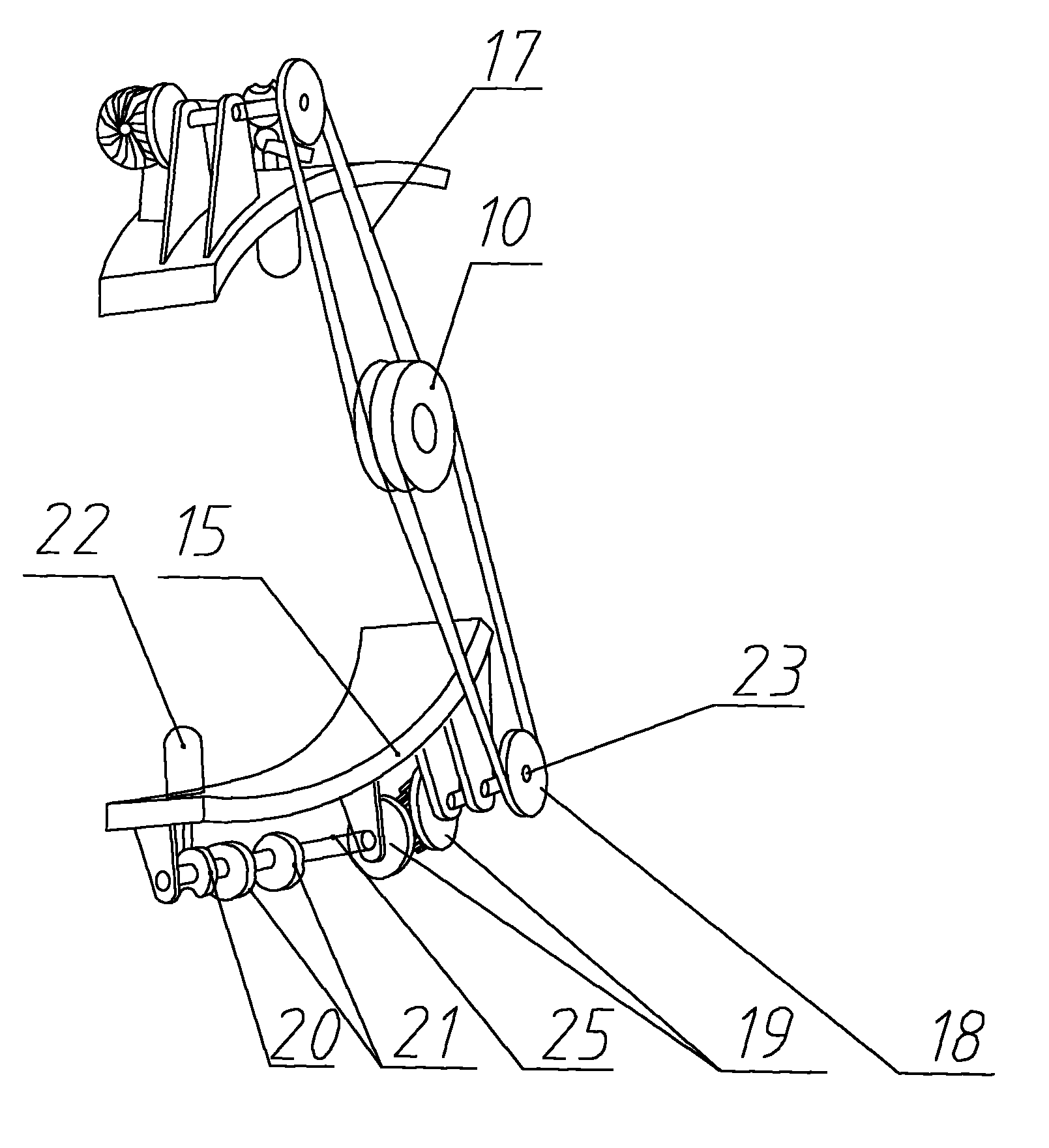

[0019] see figure 1 , the cylinder mechanism is composed of a fixed piston cylinder mechanism 4 and a timing gear 10 on the central shaft 14 on the housing, wherein the piston cylinder mechanism 4 is composed of a circular faceplate 2 with a cylindrical piston 3 and a C-shaped ring Shaped cylinder 1 is formed, and housing is formed by the connection of cylinder outer casing 5 and internal combustion engine casing 6. In the housing, the central axis 14 is connected and positioned through the bearing 7, the spring pad 8 and the fixing bolt 9, and the circular faceplate 2 with the cylindrical piston 3 is fixed in the middle of the central axis 14, and the cylindrical piston 3 is fixed on the outer circumference of the circular faceplate 2 evenly. Distribution, at least two or more. The central shaft 14 is not only the center of the circular motion of the piston of the piston rotary internal combustion engine, but also the power output shaft of the internal combustion engine. Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com