Real-time ammunition assembling instruction method based on visualized assembling system

An assembly system and ammunition technology, applied in ammunition, manufacturing computing systems, offensive equipment, etc., can solve the problems of easy mismatch, increase the overall assembly time, and reduce assembly production efficiency, so as to reduce wrong assembly, improve assembly efficiency and Accuracy, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

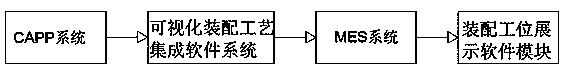

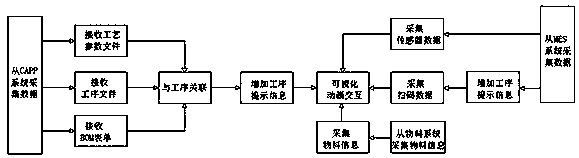

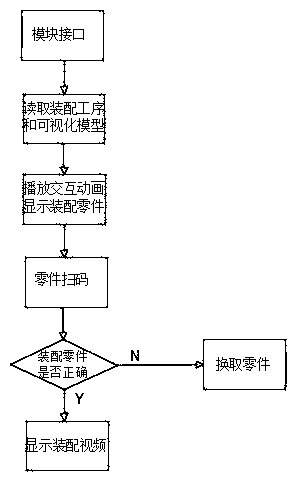

[0039] like Figure 1 to Figure 5 As shown, the present invention's

[0040] A real-time ammunition assembly guidance method based on a visual assembly system, including a visual assembly system, the system includes a sequentially connected CAPP system, a visual assembly process integration software system, an MES system, and an assembly station display software module;

[0041] The CAPP system provides correct ammunition three-dimensional parts model, correct assembly process and position data information;

[0042] The MES system completes the docking interaction between the visual assembly process integration software system and the assembly station display software module;

[0043] The visual assembly process integration software system realizes the interaction with the CAPP system and the MES system, visual assembly video processing and data modeling;

[0044] The assembly station display software module is connected with the MES system to monitor the assembly progress a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com