Quick and convenient well cementation cement permeability testing device

A technology of cementing cement and testing equipment, which is applied in measuring equipment, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem that the air tightness between the sample surface and the rubber mold is difficult to directly judge and affect the accuracy of the results In order to avoid problems such as safety and cost increase, it can achieve the effect of convenient and quick disassembly and replacement, convenient preparation, and quick and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

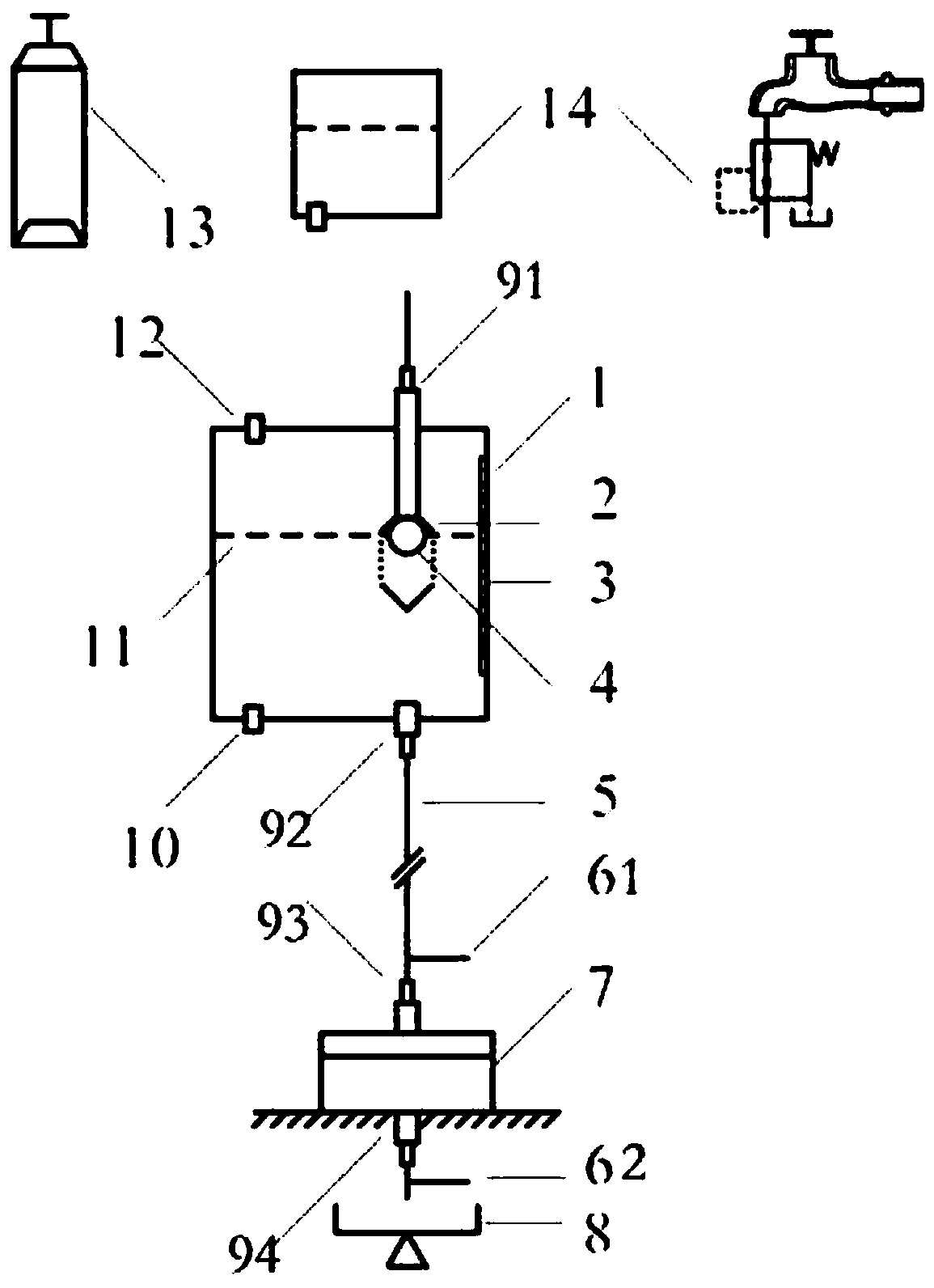

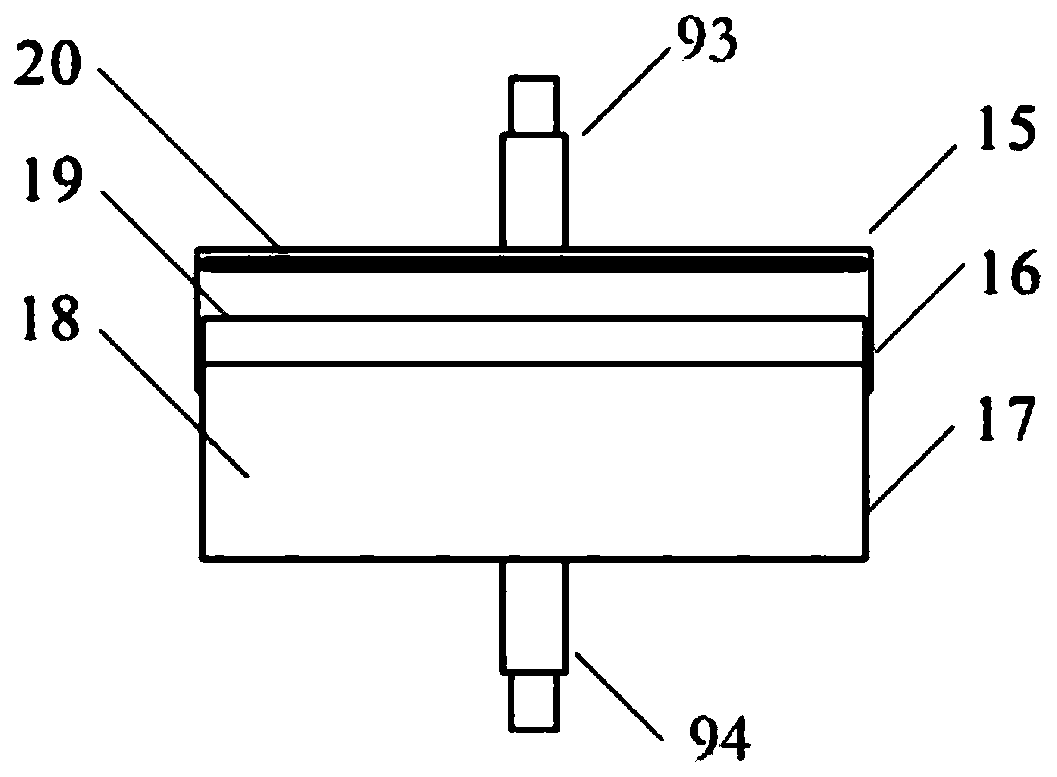

[0015] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

[0016] A fast and convenient cementing cement stone permeability testing device, comprising a water storage device, a cement stone mold 7, a water supply tank 14, and a high-pressure air source 13; the water storage device includes a box body 1; the inlet on the box body 1 The water outlet is provided with a first joint 91, and the first joint 91 is used to connect with the water supply tank 14 or the high-pressure air source 13; the bottom of the box body 1 is provided with a liquid discharge port 10; The booster device is connected; there is a liquid level controller 2 in the tank body 1, the top of the liquid level controller 2 is located at the water inlet, and the bottom is provided with a hollow rubber ball 4;

[0017] The bottom of the box body 1 is connected to the third joint 93 on the top of the cement stone mold 7 through the second joint 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com