Gasbag-based micro vibration monitoring sensor mounting device and method

A technology for microseismic monitoring and installation devices, which is applied in the field of rock engineering, can solve problems such as sensor damage, difficult operation, and inability to recover, and achieve the effects of reducing interference, reducing labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

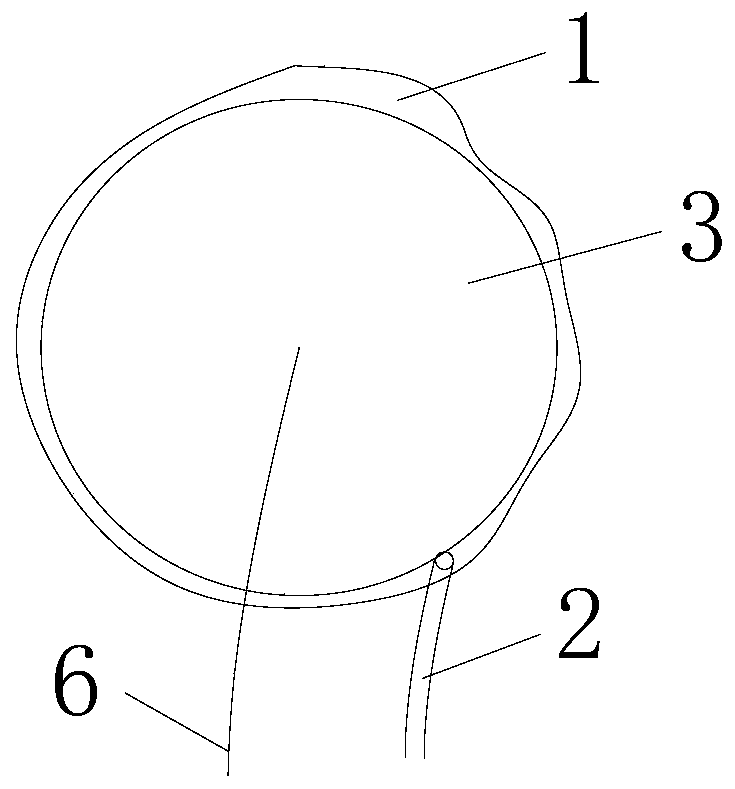

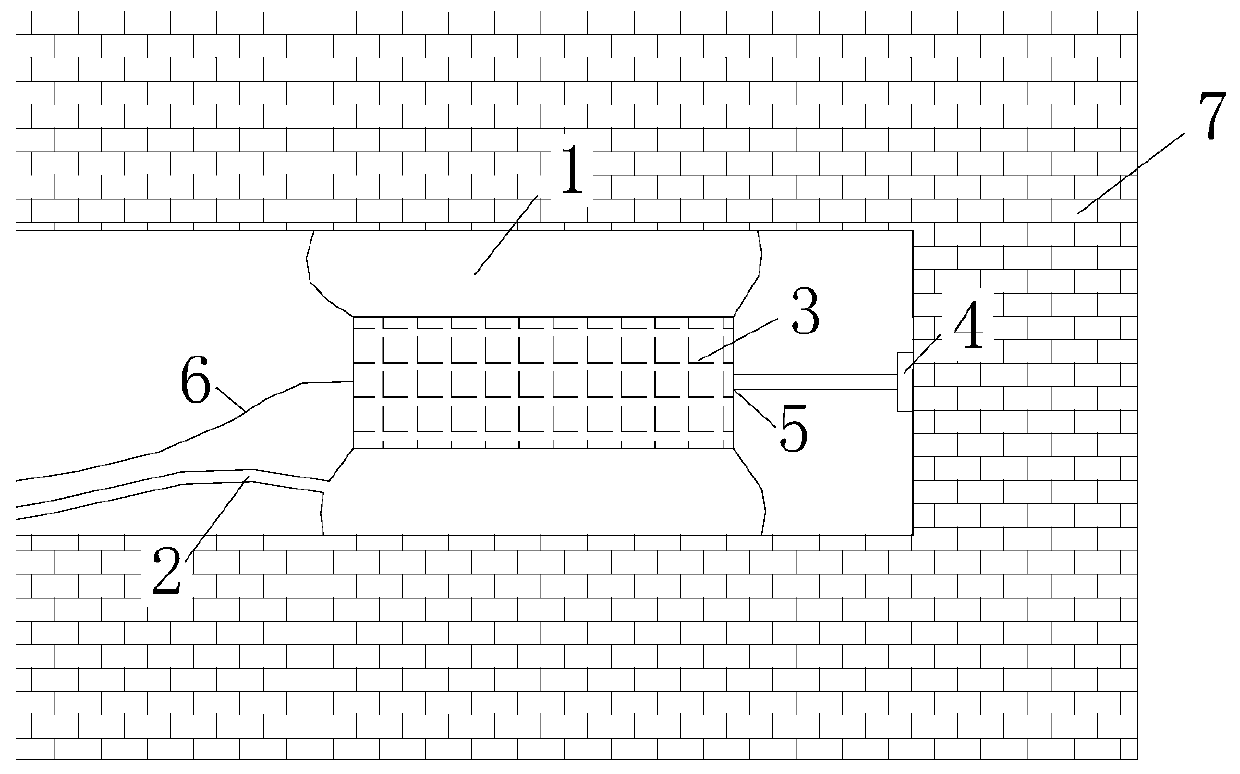

[0025] The following combined examples and attached figure 1 , 2 The present invention is described in detail:

[0026] like figure 1 , 2 As shown, the airbag tube 1 tail end is provided with an inflatable tube 2, the material used is rubber, the diameter of the airbag tube 1 is 30mm, the length is 126mm, and the inflatable tube 2 has a diameter of 4mm and a length of 3.5m.

[0027] The above-mentioned sensor 3 is provided with a threaded hole 5 at the head, and a cable 6 is connected at the tail. Sensor 3 is 126mm long and 32mm in diameter.

[0028] The bolt 4 is 40mm long, and the diameter of the circumscribed circle of the threaded part is 4mm, matching with the threaded hole 5 on the head of the sensor 3 .

[0029] After the above-mentioned bolt 4 is screwed into the threaded hole 5 of the head of the sensor 3, the above-mentioned airbag tube 1 is set on the sensor 3, and the assembly of the installation device for the microseismic monitoring sensor 3 based on the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com