Full-automatic slagging type press filter and using method thereof

A fully automatic filter press technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of large operating space, inconvenient removal of residues and replacement of filter plates, etc., to reduce operating space, reduce manual operation burden, The effect of convenient replacement of filter cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

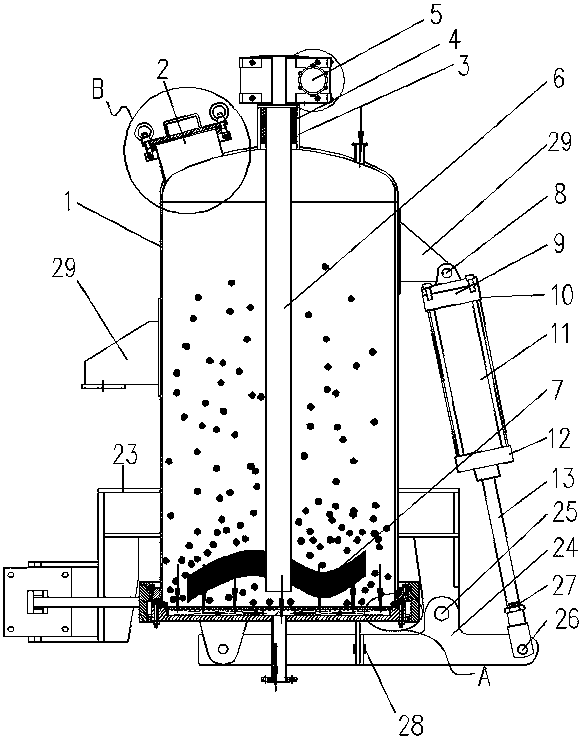

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

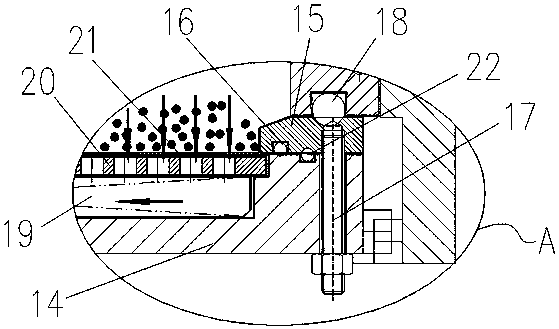

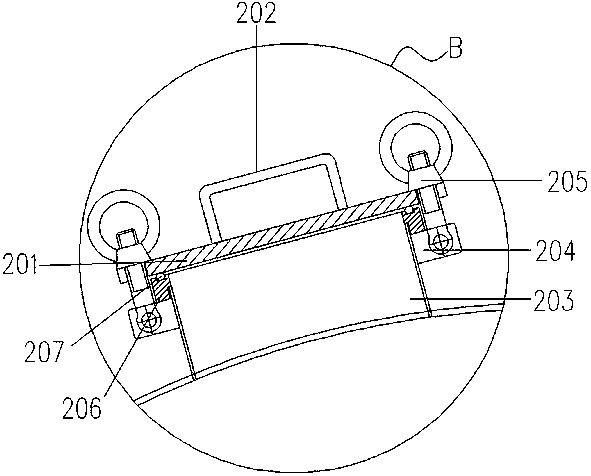

[0028] Such as Figure 1-4 As shown, a fully automatic slag discharge filter press of the present invention includes a cylinder body 1, a feed device 2 is provided on the left side of the top of the cylinder body 1, and the feed device 2 includes a feed cover 201 and a feed pipe 203, And the bottom of the feed pipe 203 is connected with the top of the cylinder body 1, the top of the feed cover 201 is fixed with a handle 202, the left and right side walls of the feed pipe 203 are symmetrically fixed with bumps 204, the feed cover 201 A second fastener 205 is inserted between the left and right sides of the top of the top and the bump 204, and the top of the bump 204 is fixedly connected with a sealing block 206, and a sealing gasket 207 is provided at the connection between the sealing block 206 and the feed cover 201, The right side of the top of the cylinder body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com