LED processing equipment and LED processing process applying LED processing equipment

A technology for processing equipment and LED chips, applied to electrical components, circuits, semiconductor devices, etc., to improve quality and yield, reduce operating steps, and reduce collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

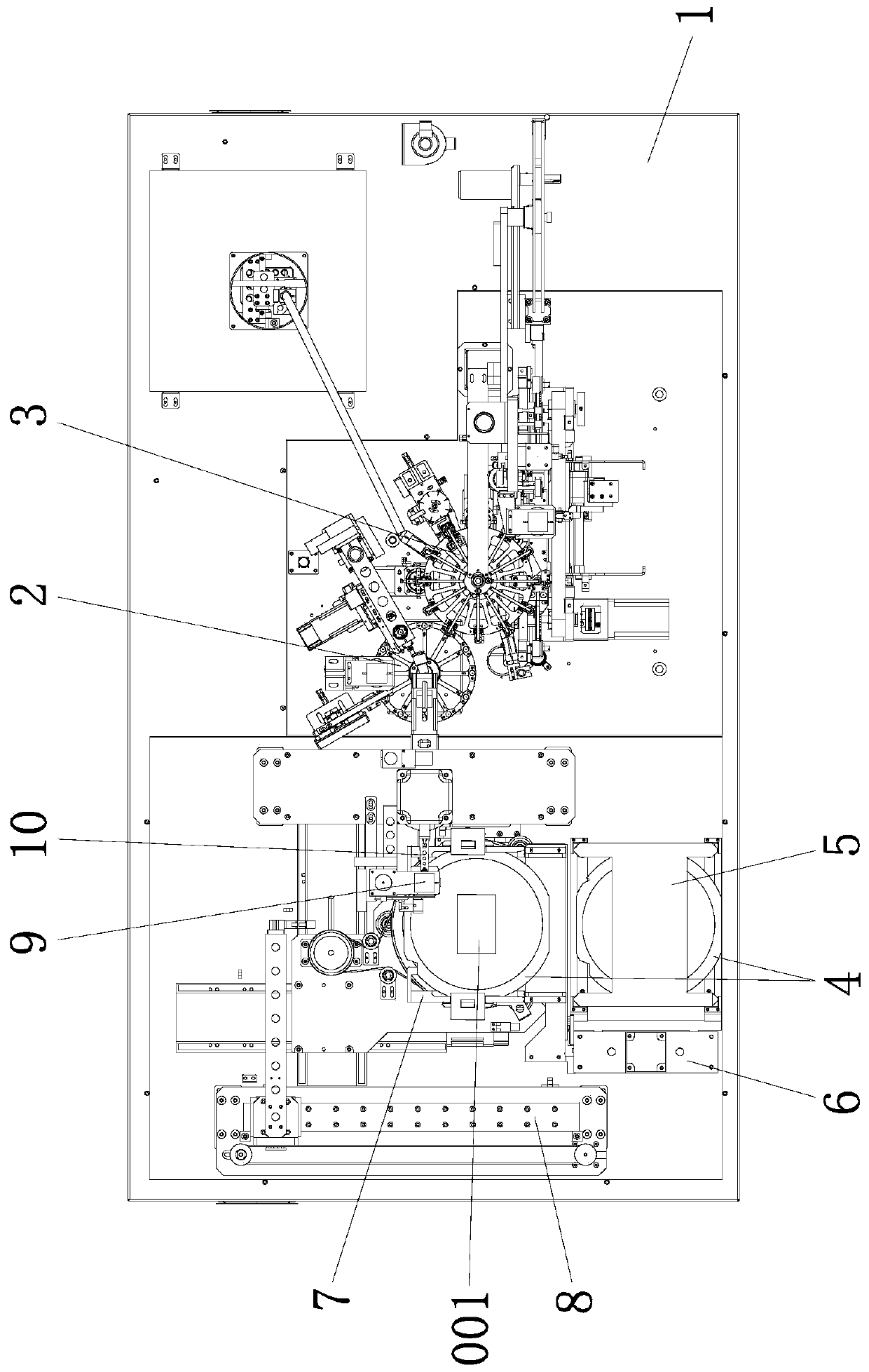

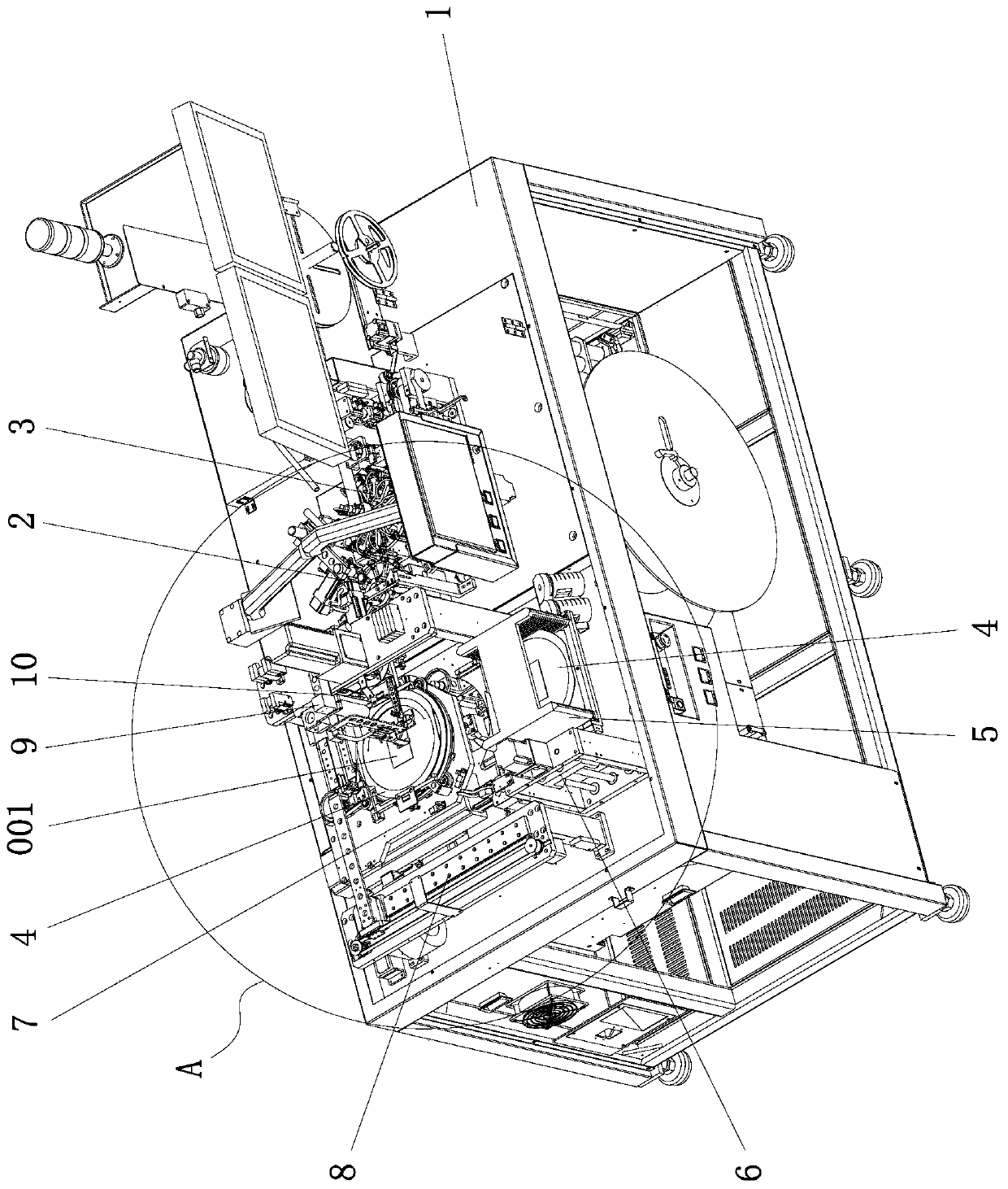

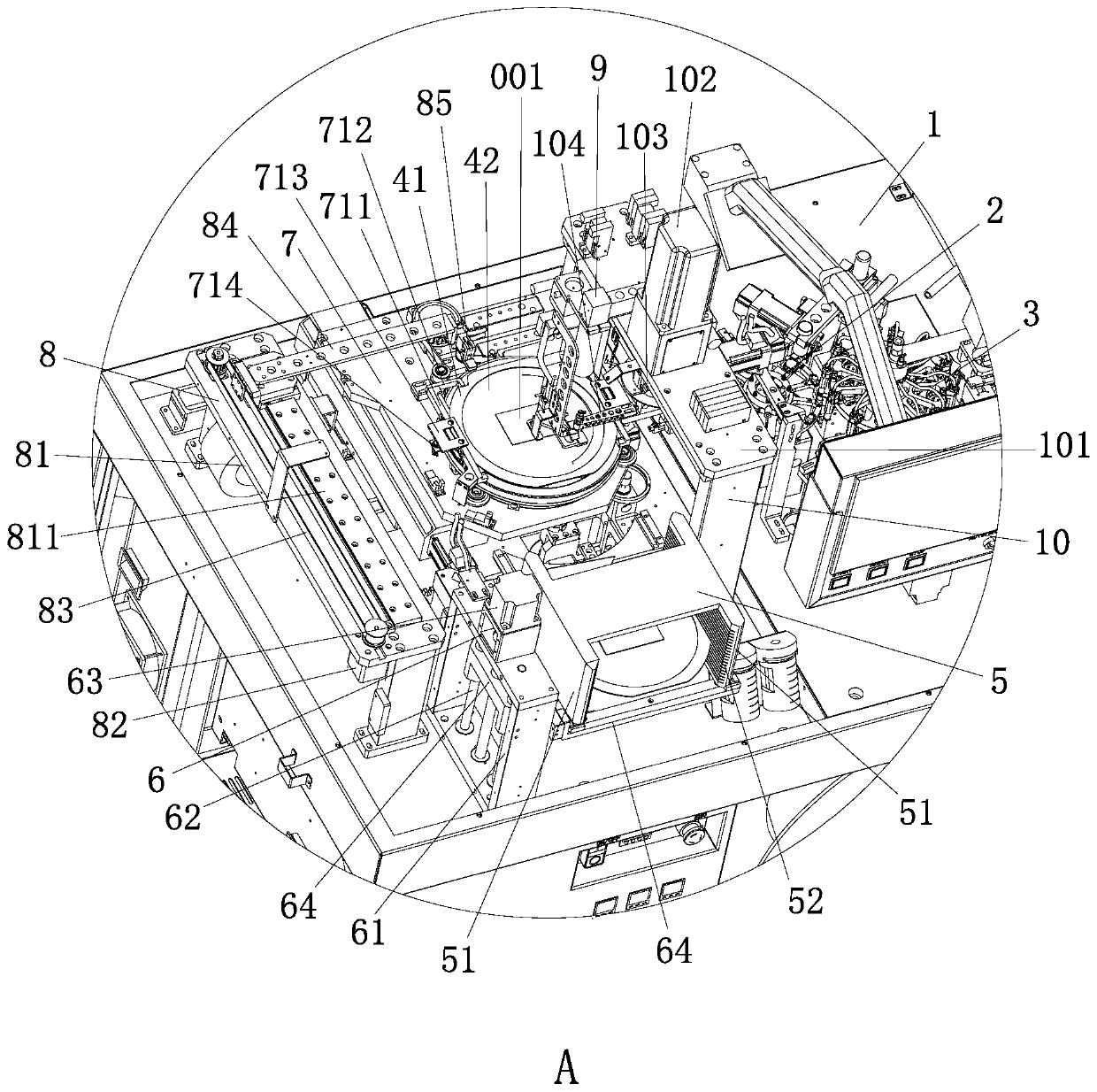

[0023] In this example, if Figure 1-3As shown, the LED processing equipment includes a base 1, a light-splitting mechanism 2 and a braiding mechanism 3, and the light-splitting mechanism 2 and the braiding mechanism 3 are arranged on the base 1. The LED processing equipment also includes: a material tray 4, a material box 5, a first feeding Mechanism 6, mobile platform 7, second feeding mechanism 8 and grabbing manipulator 10, material tray 4, material box 5, first feeding mechanism 6, mobile platform 7, second feeding mechanism 8 and grabbing manipulator 10 are all arranged on the base 1, the material box 5 is connected with the first feeding mechanism 6, the material tray 4 is arranged at intervals in the height direction in the material box 5, the material tray 4 is used to fix the LED material plate 001, and the first feeding mechanism 6 drives the material box 5 Moving in the height direction, the mobile platform 7 is positioned at one side of the magazine 5, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com