Cogging mill of high-strength deformed steel bars

A technology of rebar and blanking machine, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of increasing the blanking machine and reducing the safety of rebar processing, so as to improve the balance and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

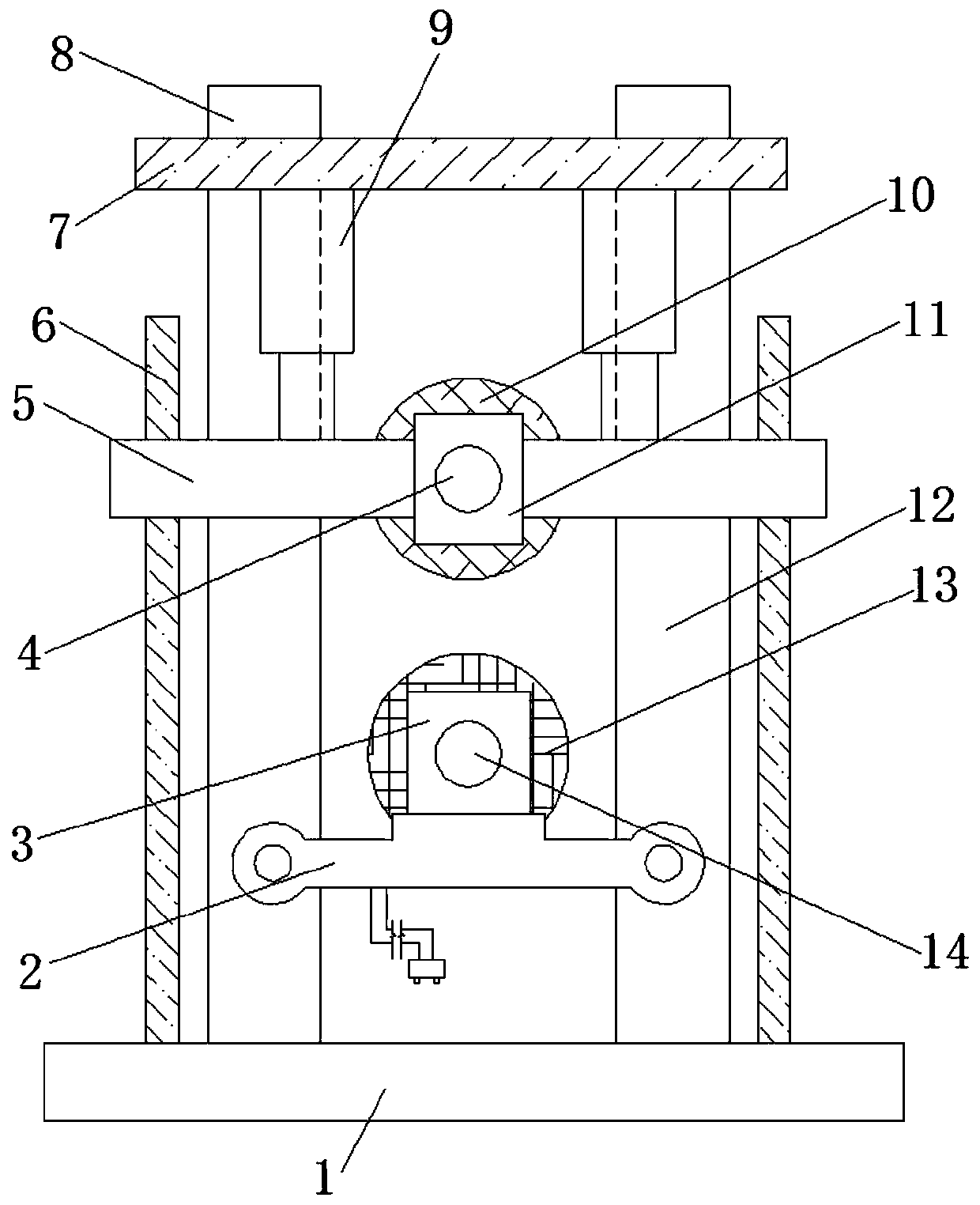

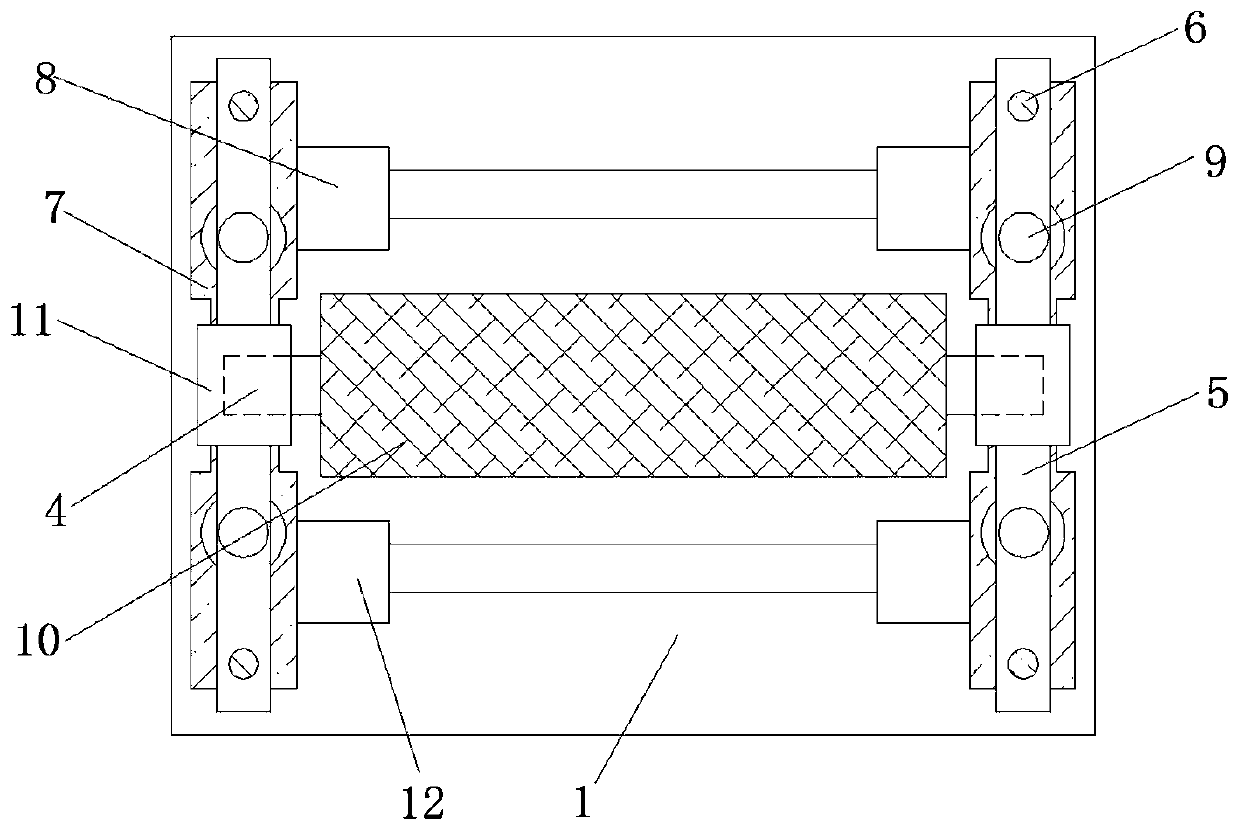

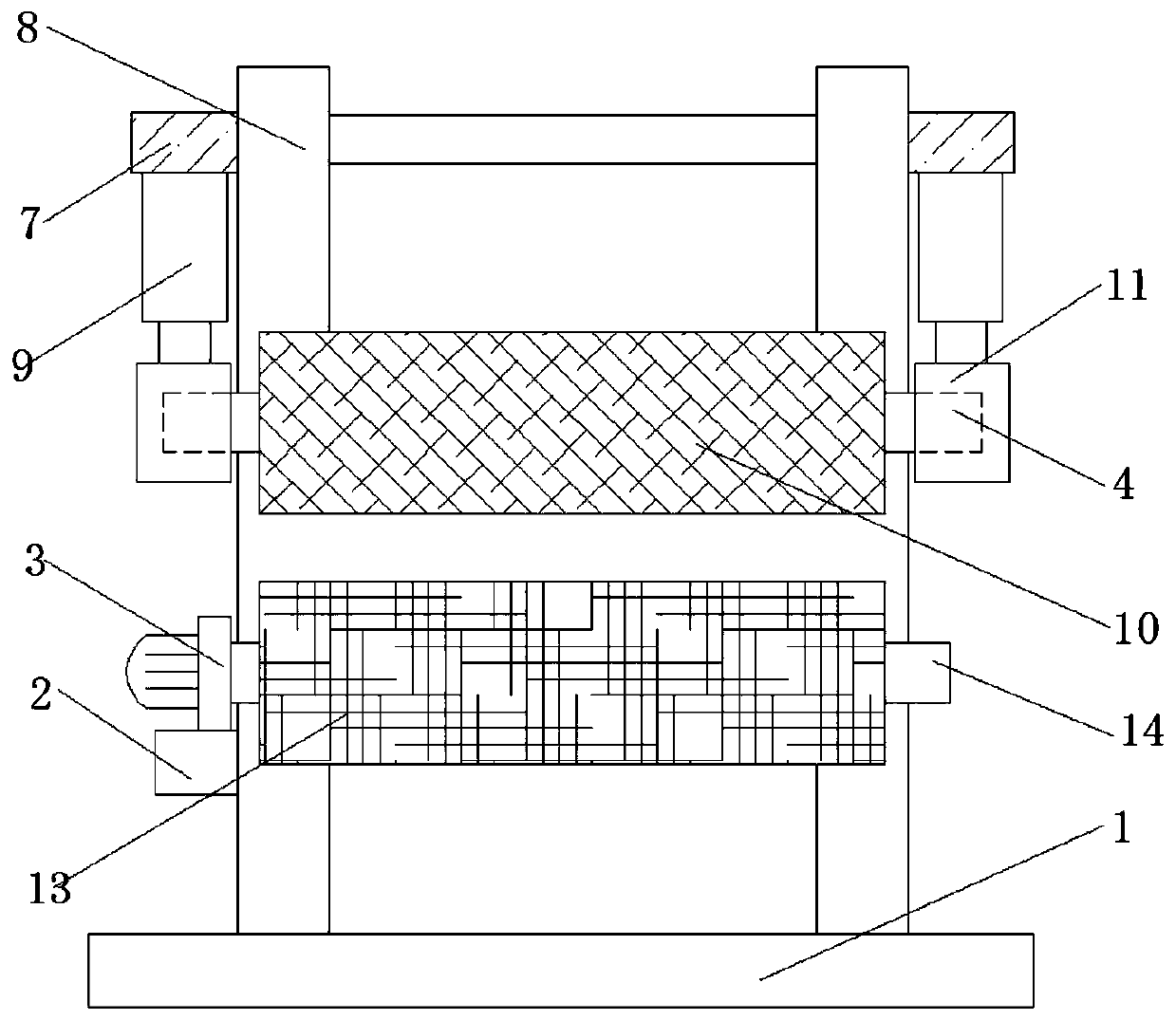

[0021] Example: refer to Figure 1-3 , a blanking machine for high-strength rebar, the middle blocks 11 are connected with upper rollers 10 through installation rods 4, the upper rollers 10 are connected with installation rods 4, and one end of the installation rods 4 is inserted into the middle block 11, the middle block 11 is arranged between the first vertical bar 8 and the second vertical bar 12 through the connecting plate 5, the opposite end of the upper side roll 10 is provided with the lower side roll 13, and the first vertical bar 8 is far away from the mounting plate 7 The side wall bolts are connected with a load-bearing plate 2, and one end of the load-bearing plate 2 is bolted to the second vertical bar 12, and the upper wall of the load-bearing plate 2 is screwed with a motor 3, and the output end of the motor 3 is connected to a rotating shaft through a coupling. The shaft 14 and the rotating shaft 14 are arranged on the lower side pressure roller, and one end w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com