Sheet metal part forming method with multi-layer combined male die adopted

A technology of sheet metal parts and punches, which is applied in the field of forming metal sheet metal parts using multi-layer combined punches, can solve problems such as quality defects, unreasonable contact and action between punches and original slabs, and achieve uniformity improvement , Save mold repair time and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

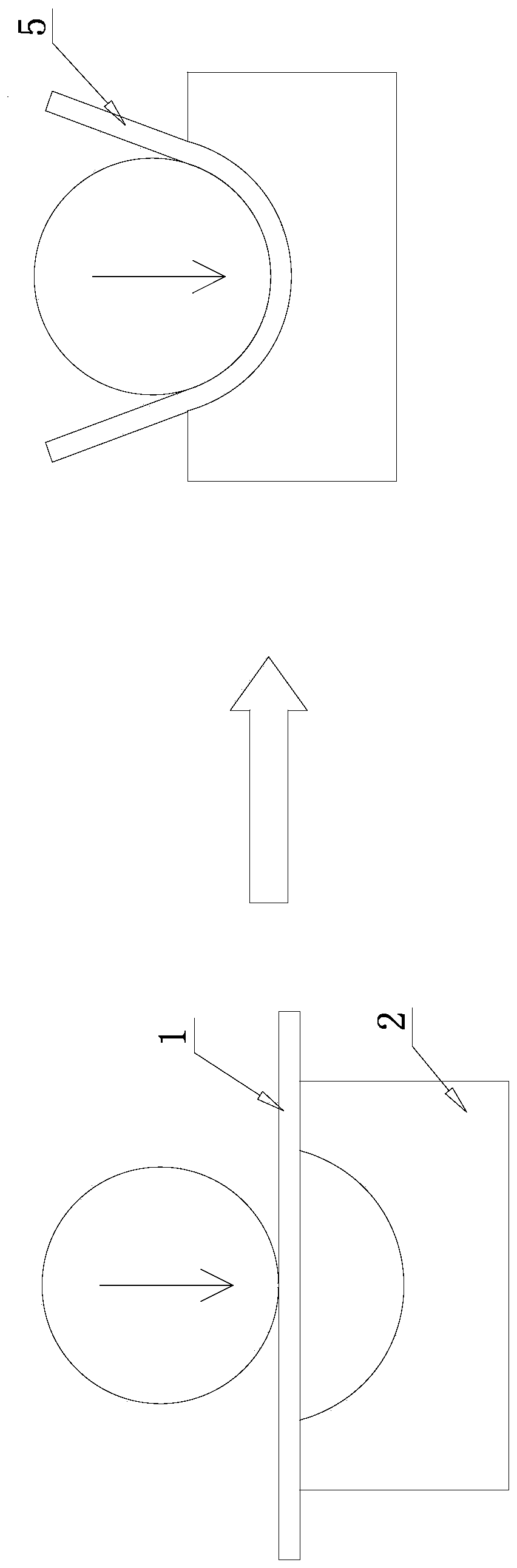

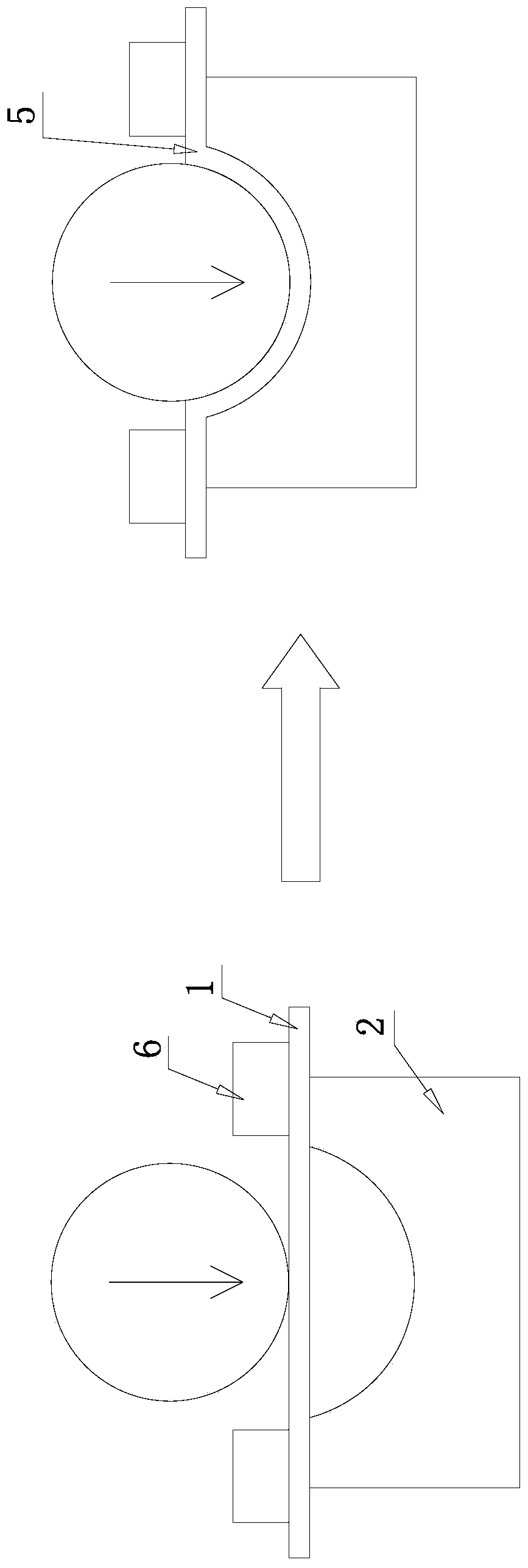

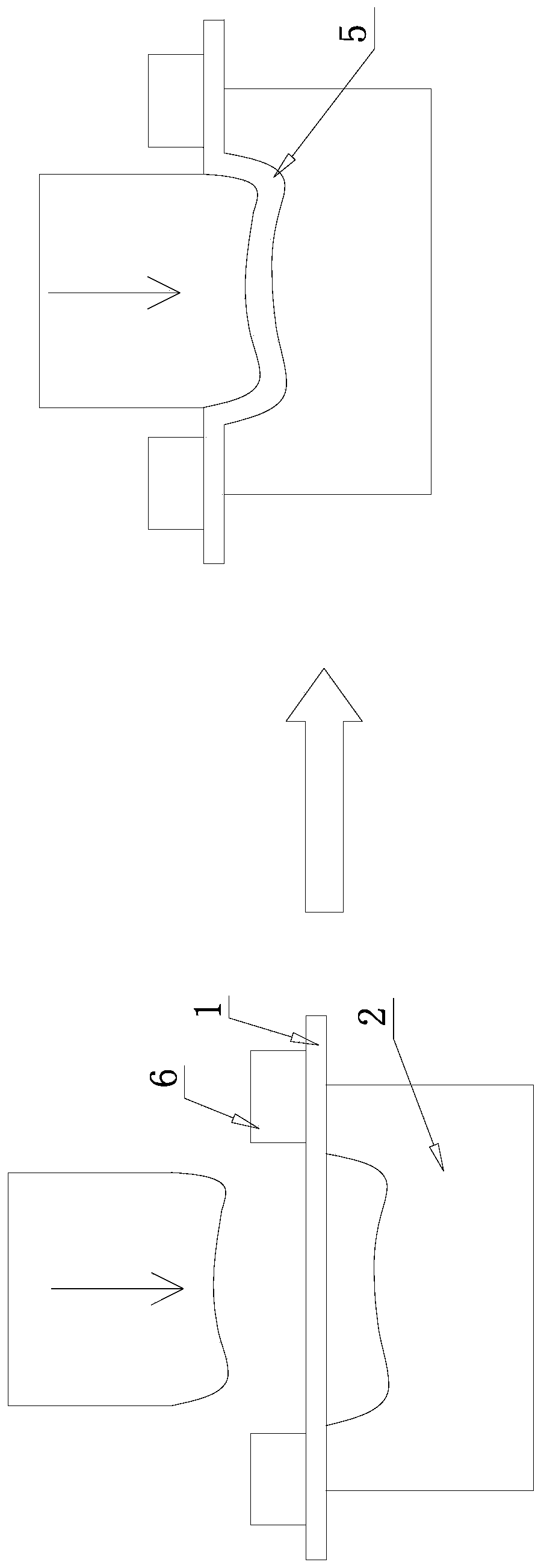

[0028] Specific implementation mode one: combine Figure 4-Figure 9 Illustrate, a kind of metal sheet metal part forming method that adopts multi-layer combined punch of this embodiment is realized according to the following steps:

[0029] Step 1, placing the blank 1 to be formed on the forming die 2 and positioning it;

[0030] Step 2, combining a plurality of plate-shaped molds 3-1 into a multi-layer combined punch 3 and positioning it at a suitable position above the blank 1;

[0031] Step 3, using the drive wheel 4 to drive the multi-layer combination punch 3, so that the multi-layer combination punch 3 gradually acts on the blank 1;

[0032] Step 4: After the blank 1 is completely fitted into the cavity of the forming die 2, the final sheet metal part 5 is obtained;

[0033] Step 5, remove the driving wheel 4 and the multi-layer combination punch 3, and remove the formed sheet metal part 5 from the forming die 2.

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 4 and Figure 5 Explain that the difference between this embodiment and the specific embodiment one is: the cavity of the forming die 2 in the step one is a circular or oval shape with a regular shape; the multilayer combined punch 3 in the step two is made of multilayer The plate mold 3-1 of about 20-50mm is formed, and the height and thickness of each plate mold 3-1 are identical and its bottom is all in contact with the upper surface of original blank 1 in initial state; In the step 3, the driving of driving wheel 4 is more The surface contour shape of the layer combination punch 3 is the same regular shape as the cavity of the die 2, and the driving wheel 4 rotates along the upper rotating shaft. Other steps and parameters are the same as in the first embodiment.

[0035] The beneficial effect of this embodiment is: since the multi-layer combination punch 3 is composed of plate-shaped molds of the same height a...

specific Embodiment approach 3

[0036] Specific implementation mode three: combination Figure 7 Explain that the difference between this embodiment and the specific embodiment one or two is: the forming die 2 in step one is an irregular shape, and the depth of the concave mold cavity changes irregularly; the multi-layer combined punch 3 in step two is It consists of multi-layer plate-shaped molds 3-1 with a thickness of 20-50mm. The height and thickness of each plate-shaped mold 3-1 are different, and the bottom of each plate-shaped mold 3-1 is in the initial state. Contact; in step 3, the surface profile of the drive wheel 4 driving the multi-layer combination punch 3 is circular, and the drive wheel 4 rotates along the upper rotation axis. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0037] The beneficial effect of this embodiment is: since the height and thickness of each plate-shaped mold adopted in step 2 are different, it is possible to obtain a punch shape that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com