Earring forging forming method

A technology of forging and earrings, which is applied in the field of forging, can solve the problems of large and small section excessive parts folding, low material utilization rate, mold cavity wear, etc., to achieve the effect of reducing forming force, reducing processing allowance, and reducing equipment tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

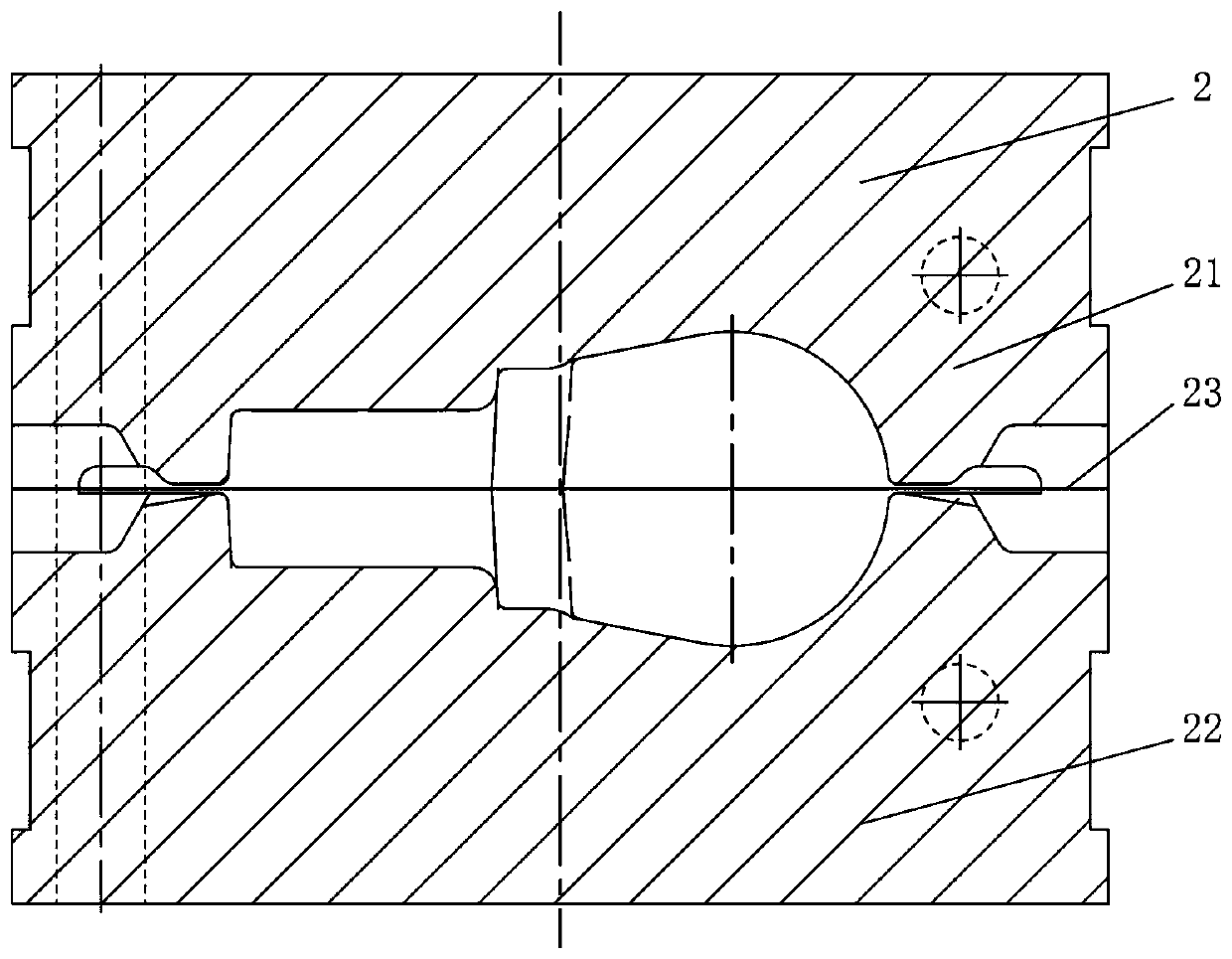

[0030] The earring forging molding method of the present embodiment comprises the following steps:

[0031] S1: Material selection: Select the appropriate bar material as the raw material according to the specifications of the required earring product, and the weight of the raw material is 1.18 to 1.2 times the weight of the earring product;

[0032] S2: Preliminary forging: the raw material in step S1 is forged into preliminary billet 1 through free forging, the process of preliminary forging includes:

[0033] S21: upsetting the raw material;

[0034] S22: Flip the upset blank by 90° and place it so that the processing surface in step S21 is perpendicular to the worktable;

[0035] S23: Continue forging to make the billet finally form the shape of the blank 1 .

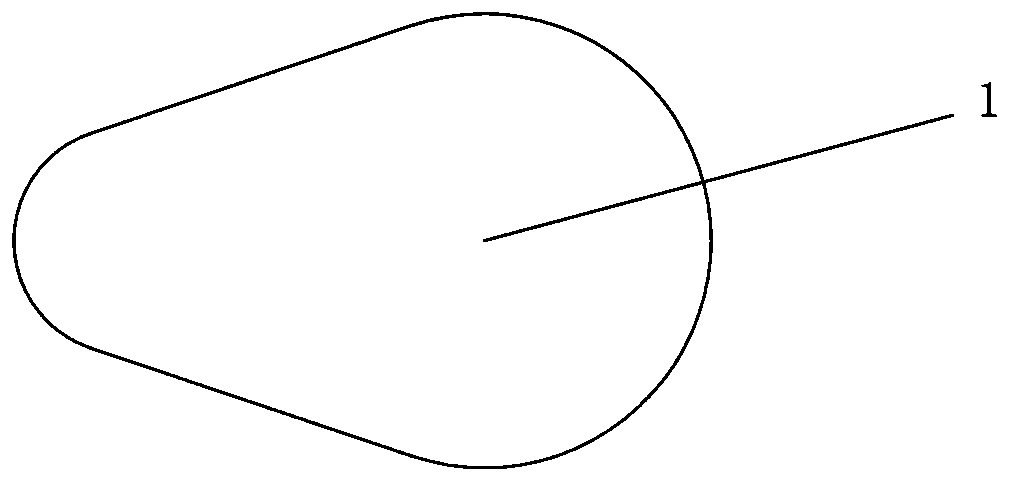

[0036] Wherein, the cross-section of the blank 1 is as follows: figure 1 As shown, it is surrounded by two outwardly protruding arcs with different diameters and two tangents connecting the two arcs; the ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com