Bamboo product processing system based on parallel joint principle

A processing system and technology of bamboo products, applied in processing models, sugarcane mechanical processing, decorative art, etc., can solve the problems of lack of coordination, inability to fix bamboo materials, and broken lines of bamboo carving products, so as to improve fluency and avoid faults Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

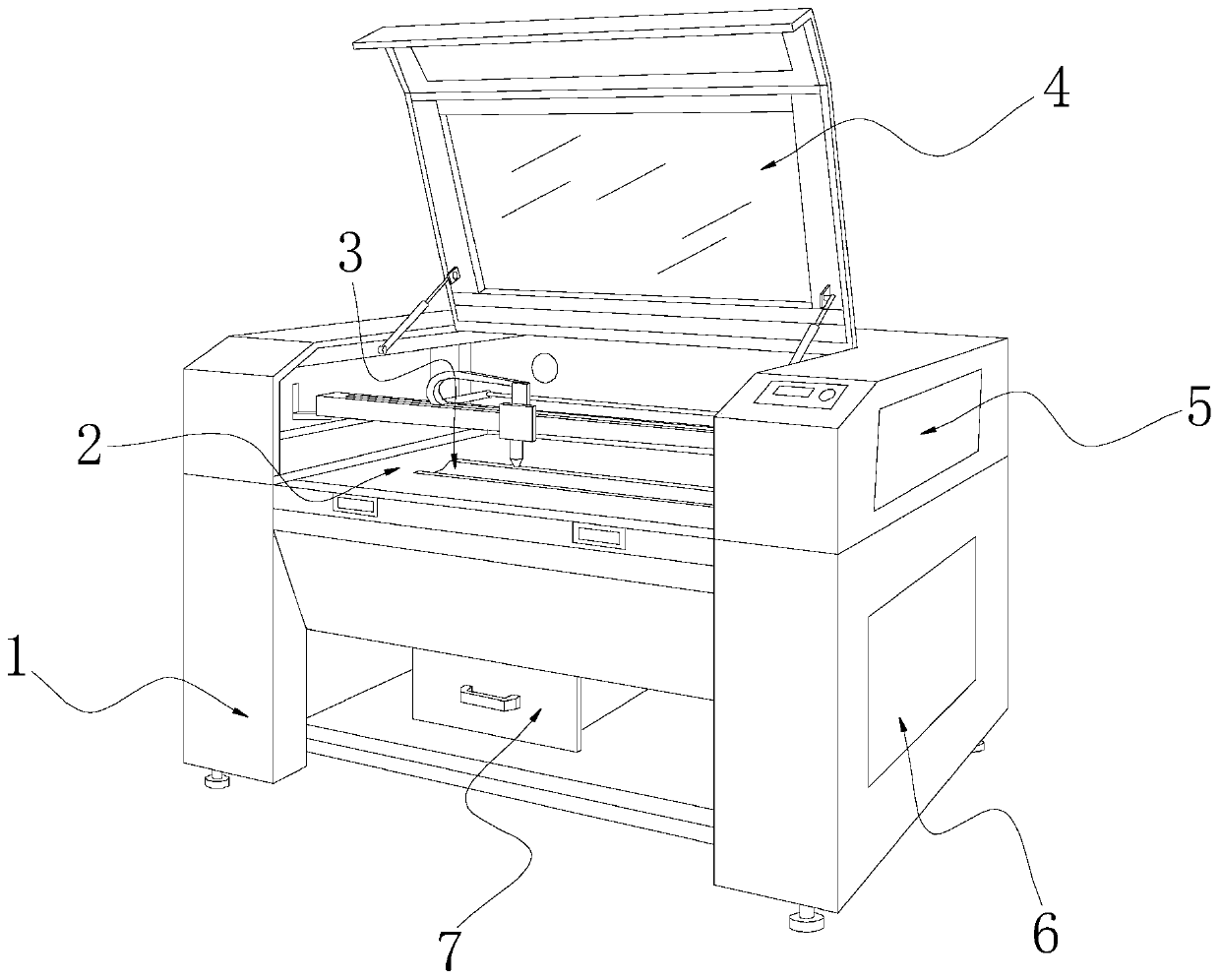

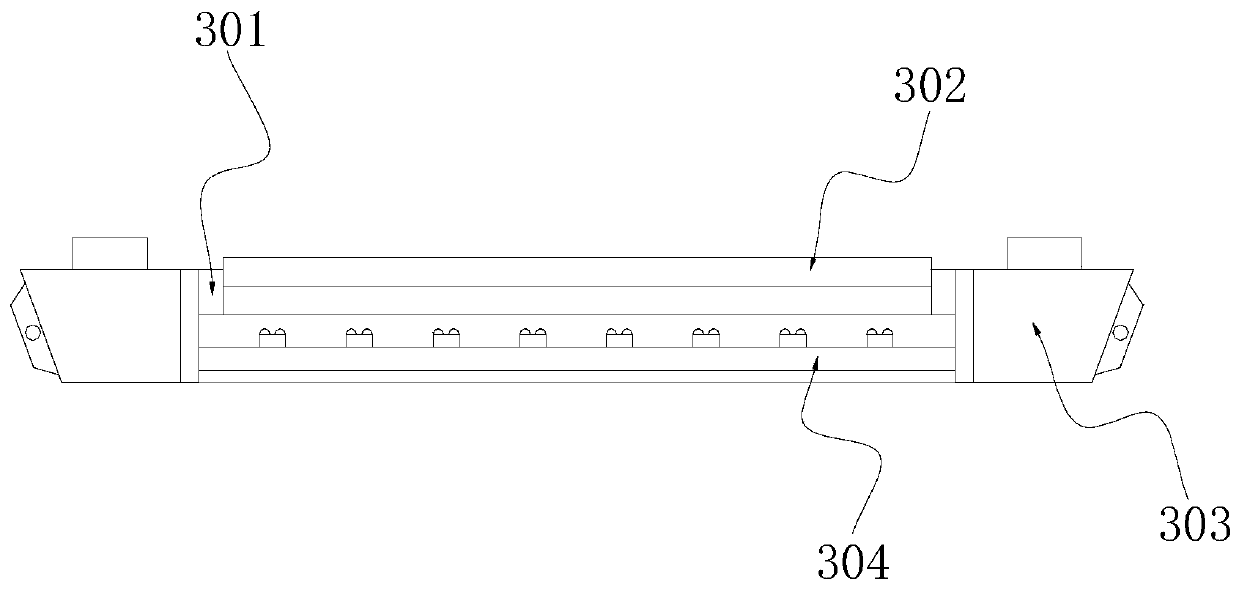

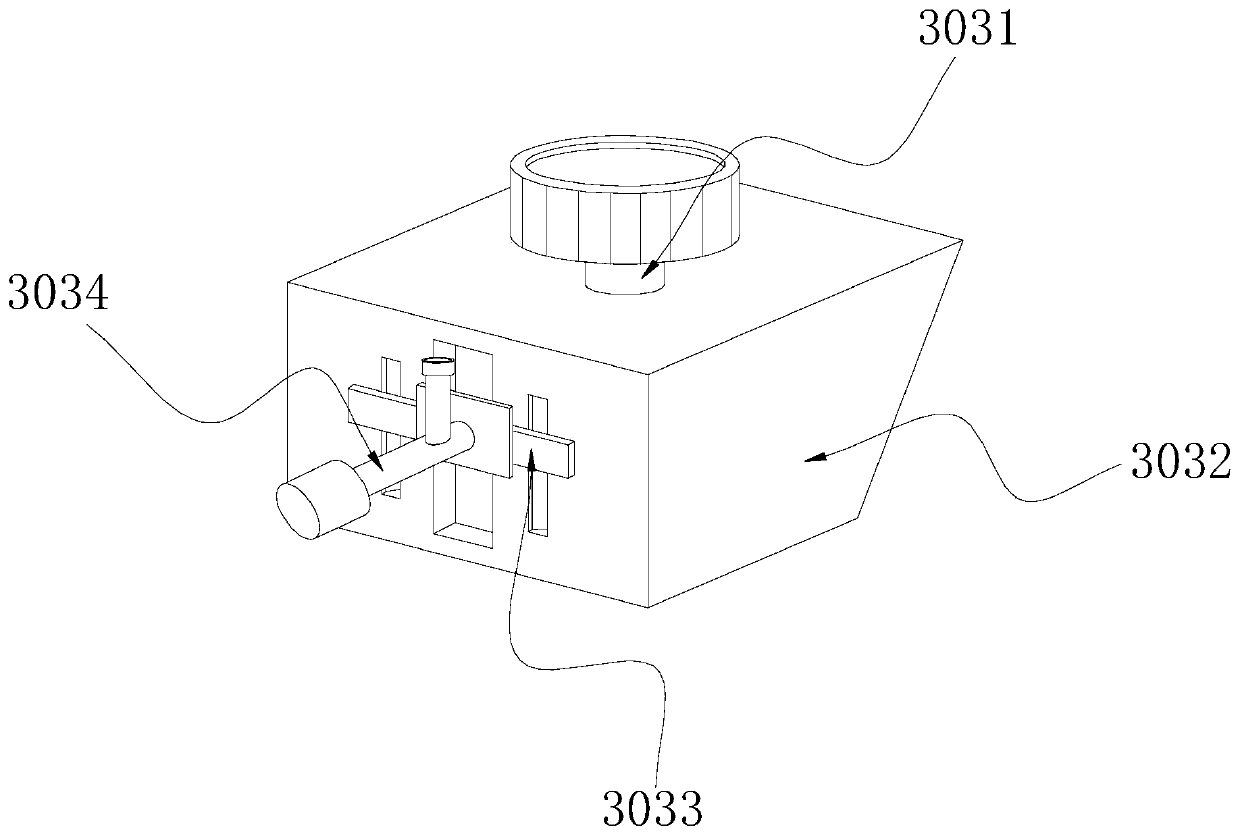

[0029] See Figure 1-Figure 7 , The present invention provides a bamboo product processing system based on the principle of parallel nodes, the structure of which includes an equipment main body 1, a processing table 2, a positioning assembly 3, a protective cover 4, a controller 5, a host 6, a tool cabinet 7, and the host 6 Installed at the right end of the equipment body 1 by snapping, the tool cabinet 7 is provided at the lower end of the middle of the equipment body 1, the upper end of the equipment body 1 is provided with a processing table 2, and the protective cover 4 is installed on the processing table 2 by snapping. At the back end, the bottom of the controller 5 is fitted with the top of the host 6, the positioning assembly 3 is installed in the middle of the processing table 2 by embedding, the product is fixed on the positioning assembly 3, and then the host 6 is activated by the controller 5 For processing, the tool cabinet 7 is used for placing processing supplie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com