Three-primary colors based dyeing and variable-frequency color change magnetic control device of 3D printer

A technology of 3D printers and magnetic control devices, applied in manufacturing auxiliary devices, 3D object support structures, additive manufacturing, etc., can solve problems such as poor printing quality, and achieve the effect of easy adjustment and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

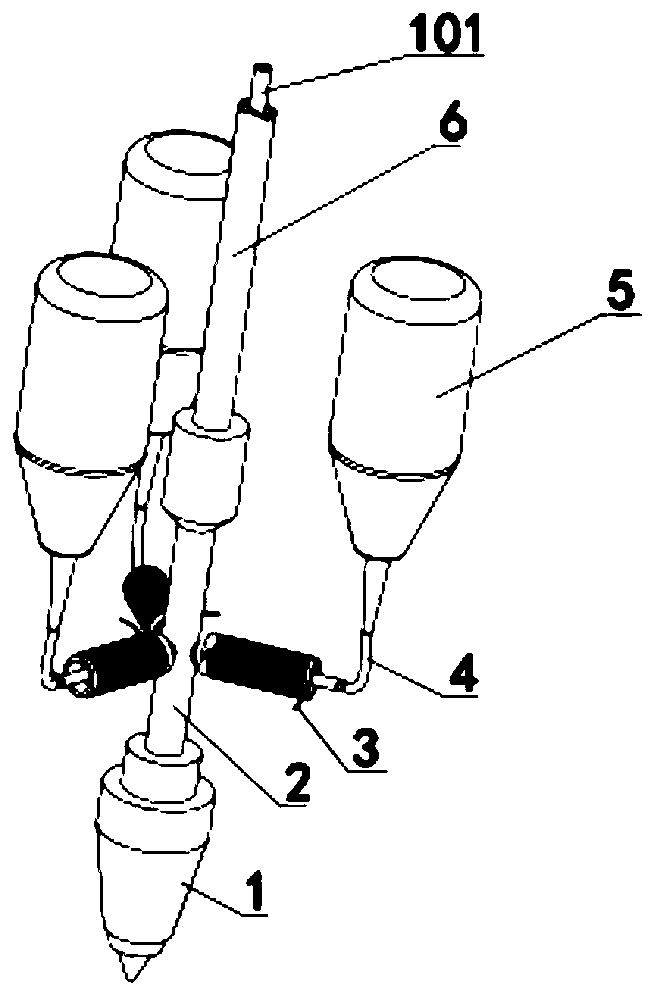

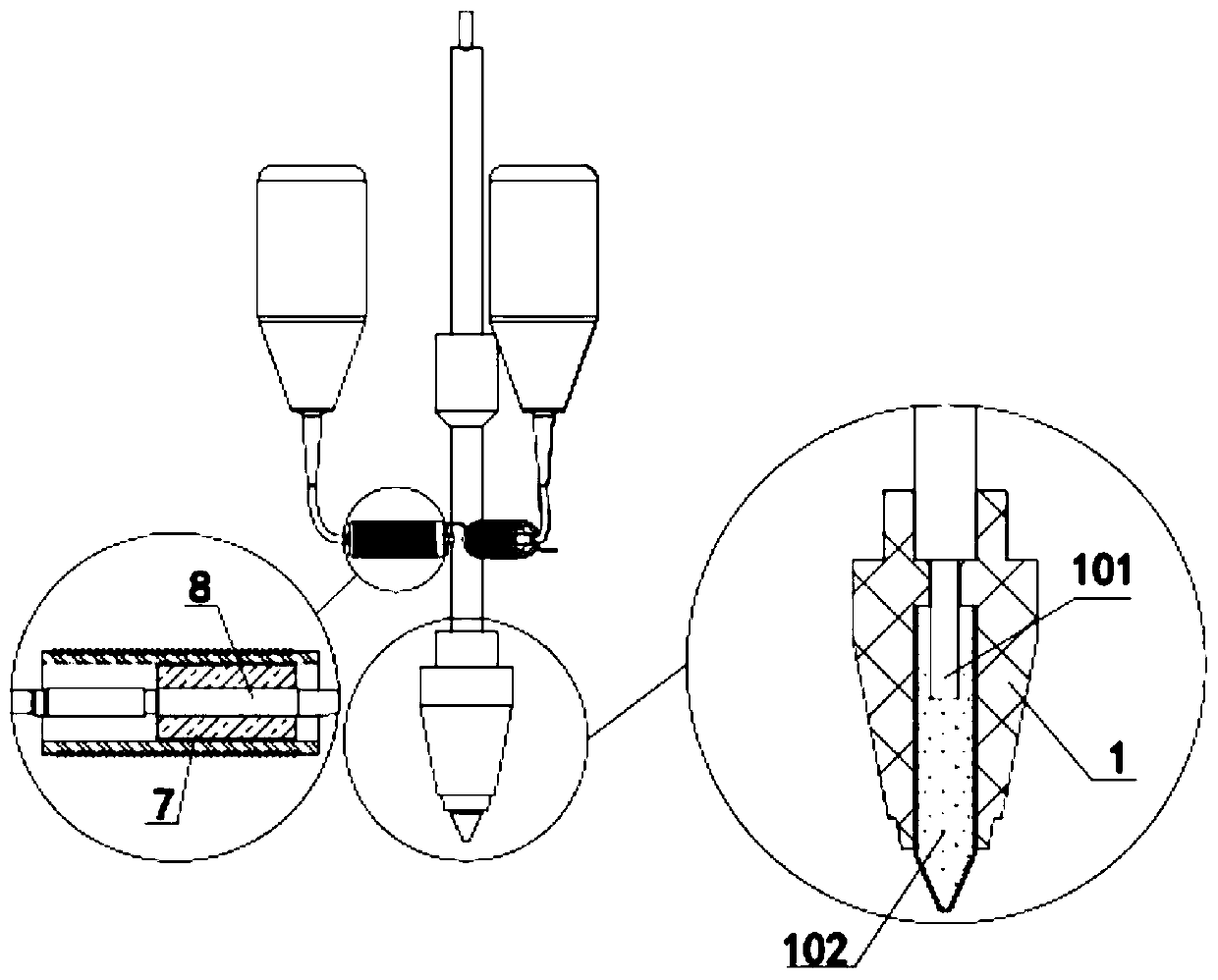

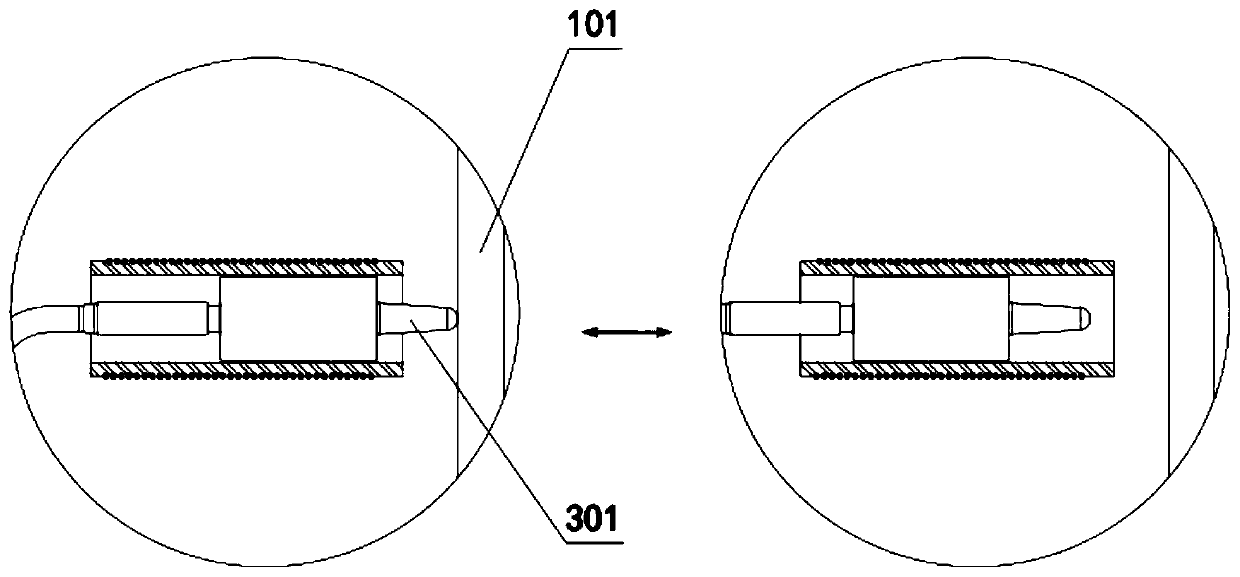

[0022] combined with figure 1 As shown, a 3D printer dyeing and color-changing frequency conversion magnetic control device based on three primary colors includes three ink cartridges 5, and also includes a print head assembly 1, a dyeing chamber 2 connected to the rear end of the print head assembly 1, and a dyeing chamber 2. The feeding pipe 6; the dyeing chamber 2 is provided with three magnetron coil assemblies 3 communicated with the dye chamber 2, and the magnetron coil assemblies 3 are respectively connected to the ink cartridge 5 through a flexible hose; as figure 2 As shown, the print head assembly 1 includes a print head, and the middle of the print head is a filament 101 melt cavity, and the filament 101 runs through the filament 101 melt cavity, the dyeing cavity 2 and the feeding pipe 6, and the The silk material 101 runs through the dyeing chamber 2 and the feeding pipe 6. When printing, the silk material 101 enters the dyeing chamber 2 from the feeding pipe 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com