Three-coordinate adjustable-angle carving machine

An angle-adjusting, engraving machine technology, applied in the field of engraving machines, can solve the problems of not being suitable for mass production and unrecorded technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

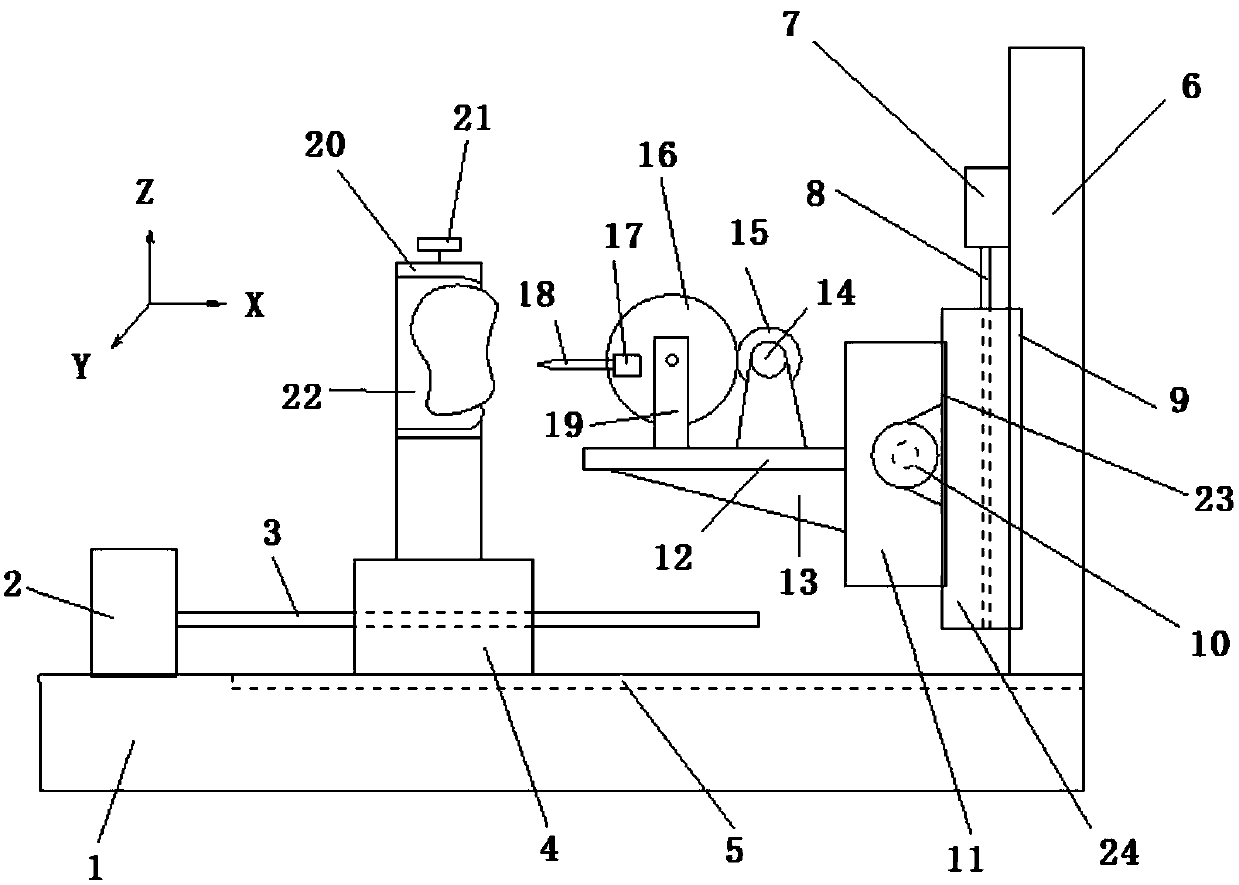

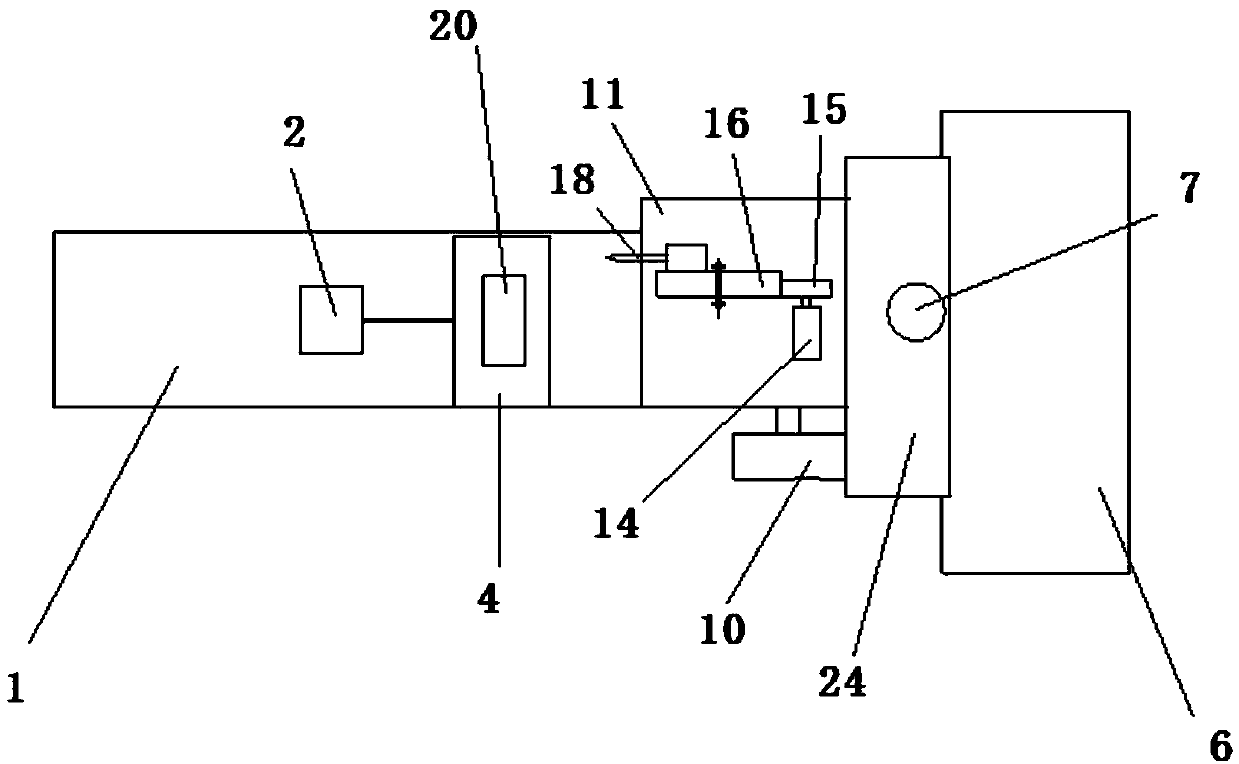

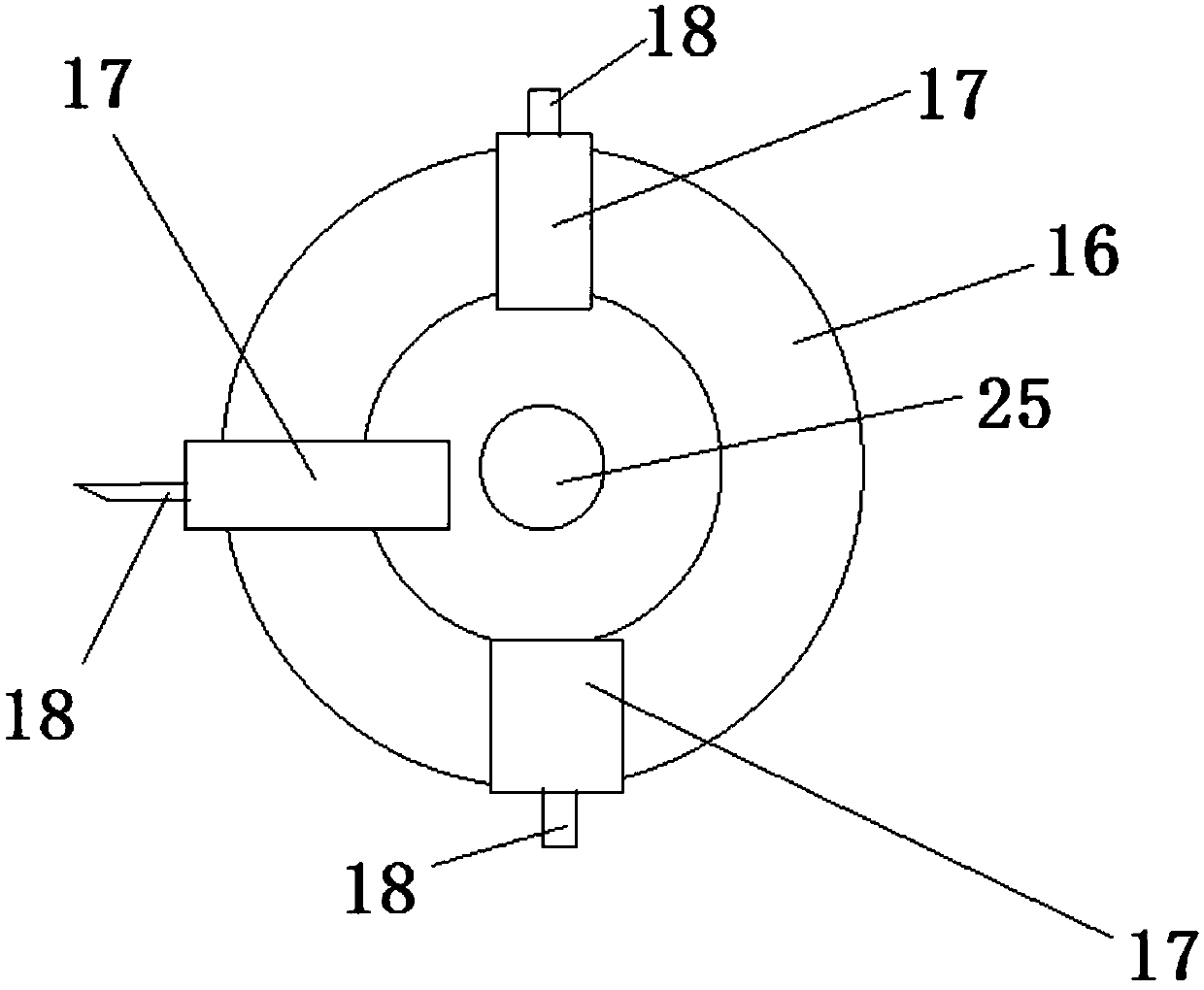

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 3 As shown, the base 1 of the present invention is provided with an X-axis motor 2 on the base 1, and the X-axis motor 2 drives the X-axis slider 4 to slide left and right along the X-axis track 5 on the base 1 through the X-axis screw 3; A support base 6 is also fixed on the base 1, and a Z-axis motor 7 is fixed on the support base 6. The Z-axis motor 7 drives the Z-axis slider 24 along the Z-axis track 9 on the support base through the Z-axis screw 8. Sliding up and down; the Z-axis slider 24 is fixed with a Y-axis motor 10, and the Y-axis motor 10 also utilizes a screw to drive the Y-axis slider 11 to slide back and forth along the Y-axis track 23 on the Z-axis slider 24; A support plate 12 is fixed on the Y-axis slider 11, and a vertical plate 19 and a rotating motor 14 are fixed on the support plate 12; the rotating motor 14 drives a pinion 15 to rota...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap