Continuous speed-changing shunt type hybrid power assembly

A technology of hybrid power and hybrid power modules, which is applied in the direction of hybrid vehicles, power devices, air pressure power devices, etc., can solve the problems of high fuel consumption and poor shifting quality, and achieve low fuel consumption, high shifting quality, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

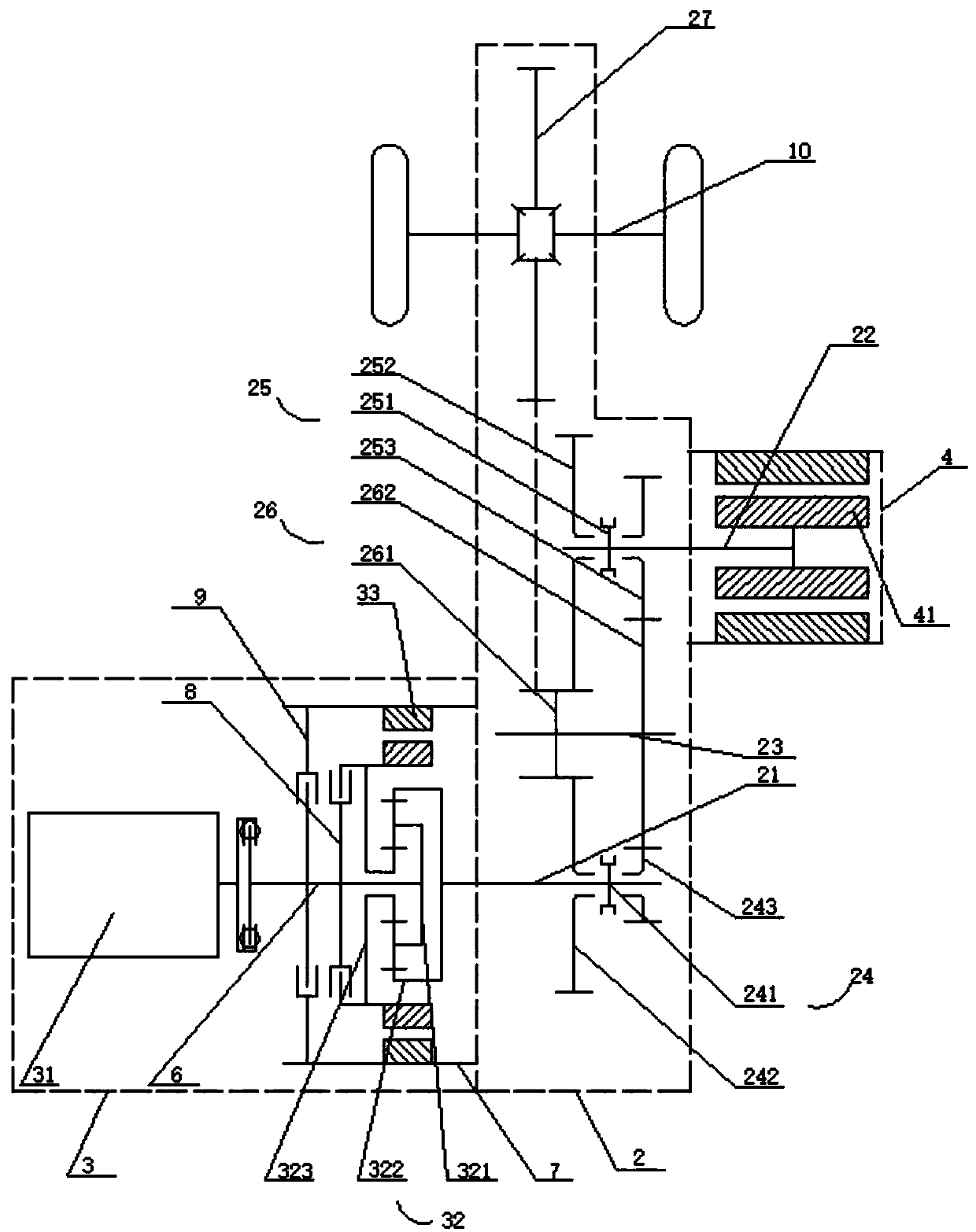

[0033] This embodiment provides a structure of a continuously variable split-flow hybrid powertrain, see figure 1 , the continuously variable split-flow hybrid powertrain includes a hybrid module 3, an electric module 4 and a gear shift module 2;

[0034] The gear shifting module 2 includes a first input shaft 21, a second input shaft 22, a first gear shifting mechanism 24, a second gear shifting gear 25 and an output shaft 23, and one end of the first input shaft 21 is connected to The power output end of the hybrid module 3 is connected, the other end of the first input shaft 21 is connected to the output shaft 23 through the first shift mechanism 24, and one end of the second input shaft 22 is connected to the The power output end of the electric module 4 is connected, and the other end of the second input shaft 22 is connected to the output shaft 23 through the second gear shift mechanism 25;

[0035] Wherein, both the first shifting transmission mechanism 24 and the seco...

Embodiment 2

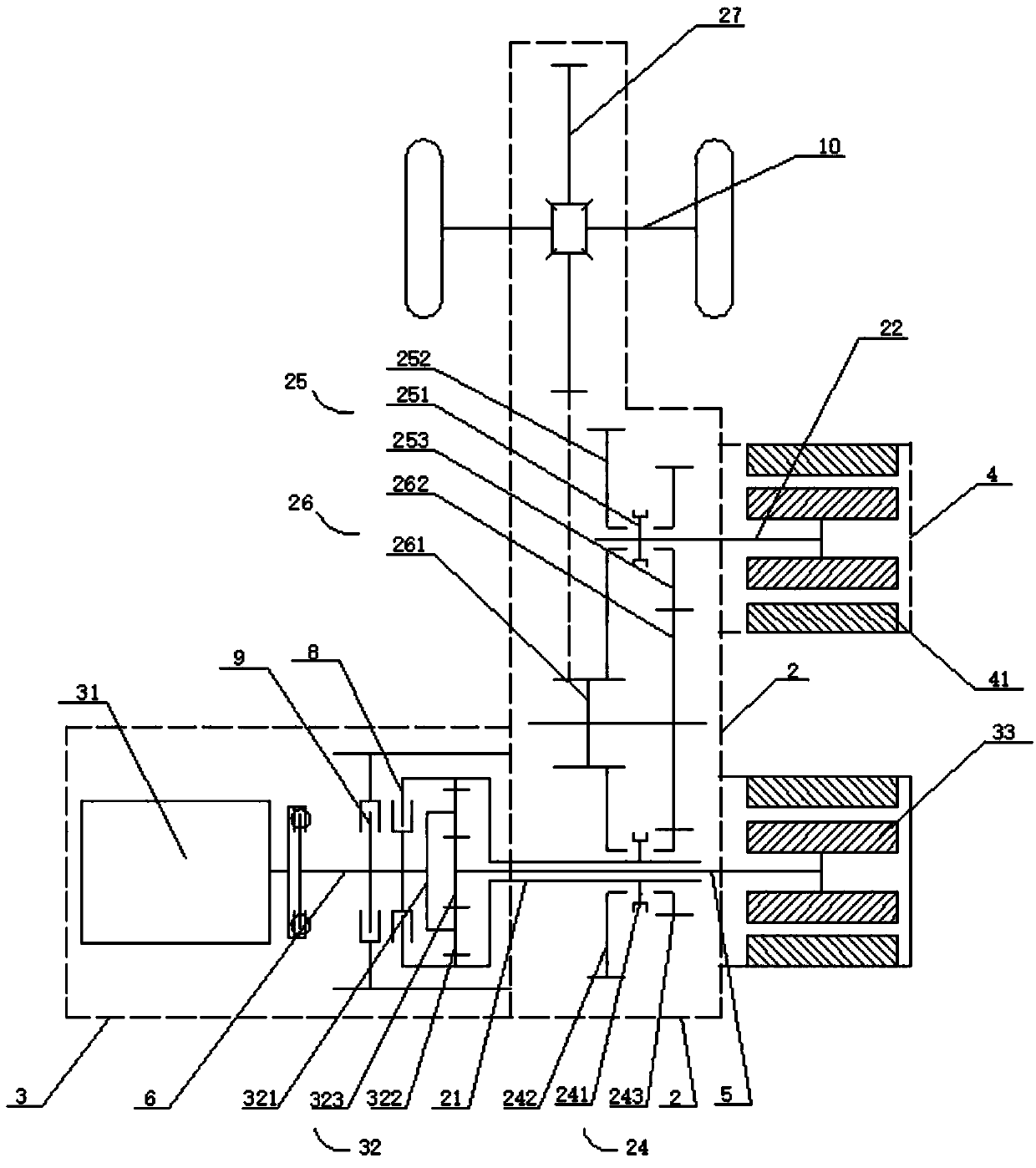

[0073] In this example, see figure 2 The difference from the first embodiment is that the first motor 33 is connected to the hybrid module 3 through the first transmission shaft 5 instead of the first motor 33 directly connected to the hybrid module 3 in the first embodiment. And after adding the first transmission shaft 5, the first input shaft 21 is set in a cylindrical shape, the first input shaft 21 is sleeved outside the first transmission shaft 5, and the connection relationship between other parts There is no change, and the function realized by this structure is the same as that realized in the first embodiment.

Embodiment 3

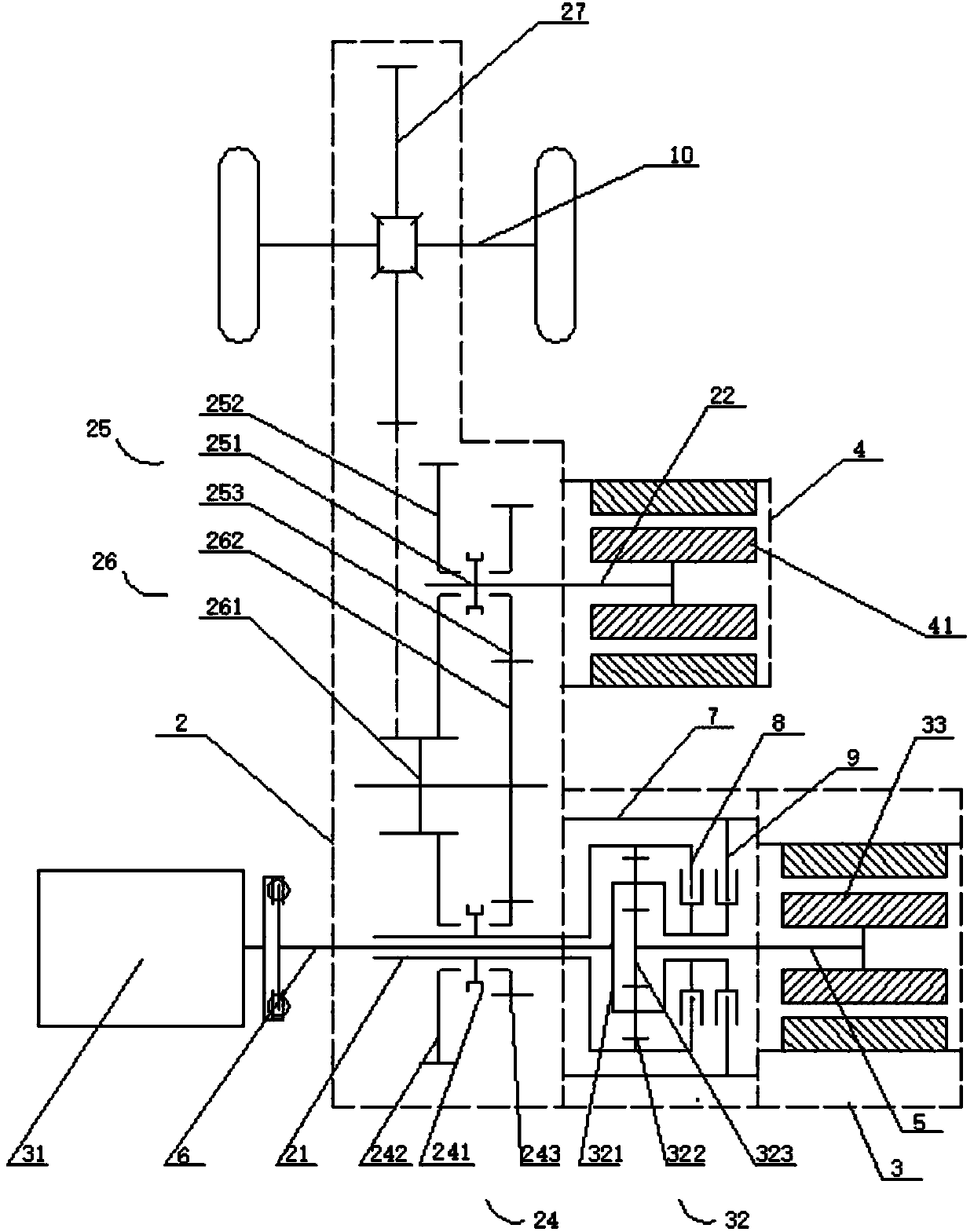

[0075] In this example, see image 3 , different from the second embodiment, in this embodiment only the positions of the shift transmission module 2 and the hybrid module 3 are exchanged, that is, the first input shaft 21 is sleeved on the second The connection relationship between other parts outside the transmission shaft 6 has not changed, and the function realized by this structure is the same as that realized in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com