Taking and transferring device

A technology of transferring device and reclaiming mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of many driving sources, slow speed and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

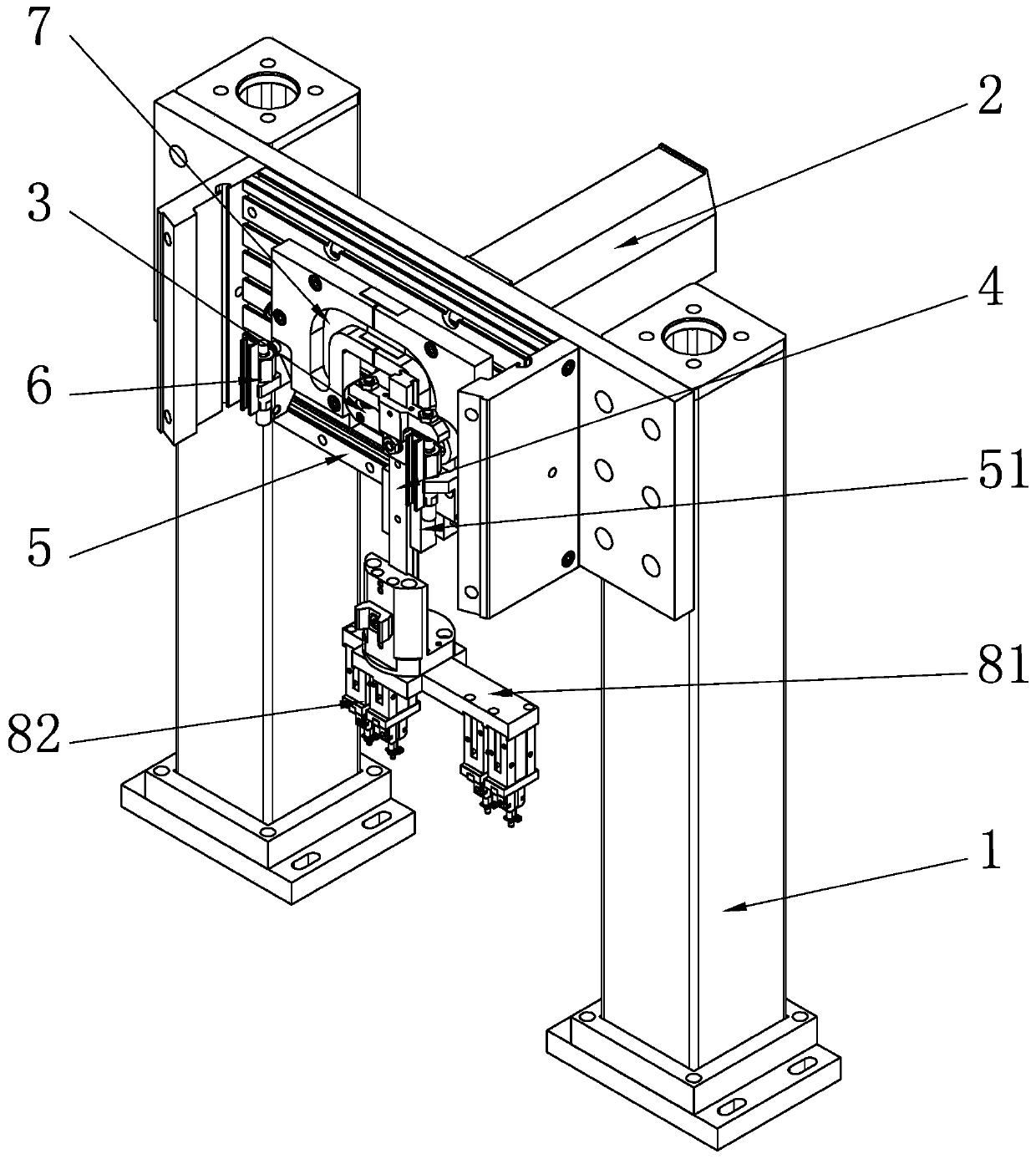

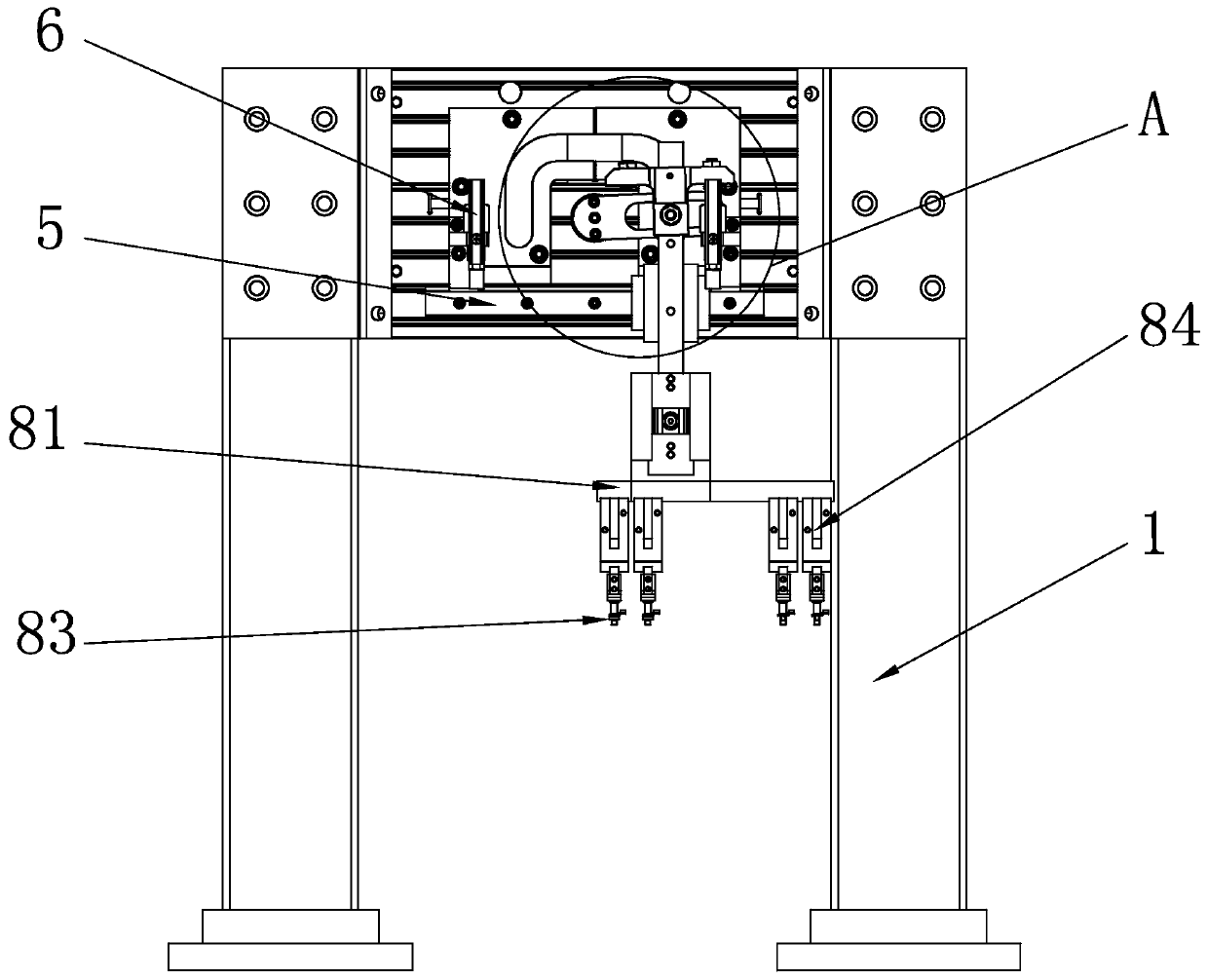

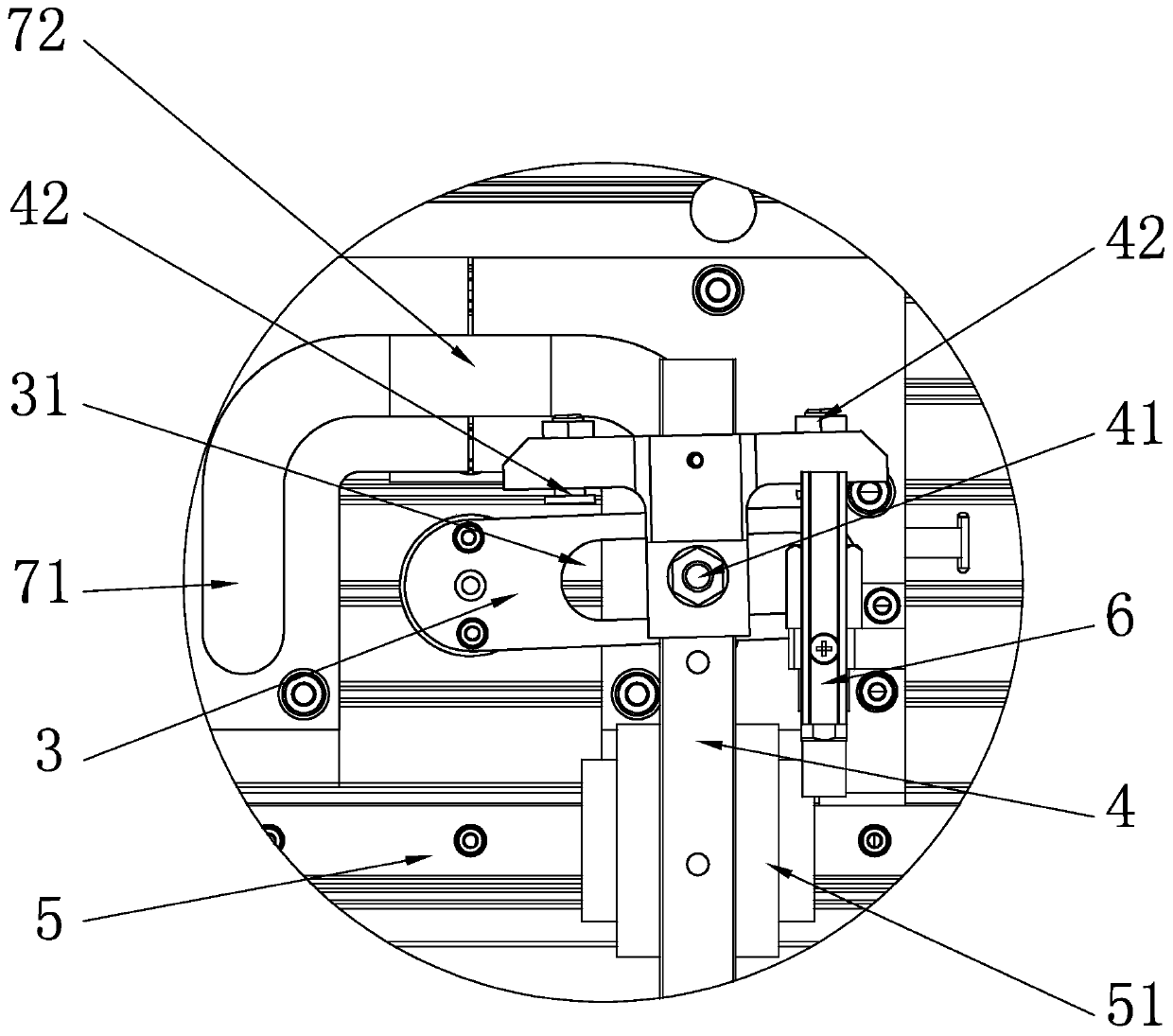

[0021] see figure 1 , a kind of fetching and transferring device of the present invention comprises frame 1, slide bar 4 and the rotary driving device 2 that is located at frame 1, and the output shaft of described rotary driving device 2 is fixedly connected with fork 3, and described The swing bar 3 is provided with a waist-shaped hole 31, and the slide bar 4 is passed through the guide wheel 41 in the waist-shaped hole 31. The frame 1 is provided with an inverted U-shaped guide groove 7, and the slide bar 4 passes through the waist-shaped hole 31. The guide wheel 41 slides in the inverted U-shaped guide groove 7, the lower end of the slide bar 4 is provided with a material retrieval mechanism 8, and the material retrieval mechanism 8 can grab or put down the knob, and the frame 1 is horizontally provided with a slide rail 5. The slide rail 5 is provided with a slide block 51, and the slide block 51 is vertically provided with a chute, and the slide bar 4 can slide up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com