Parasitic mechanism type space-controllable excavating mechanism

A mechanism-based, space-based technology, applied to mechanically driven excavators/dredgers, etc., can solve problems such as high manufacturing precision, insufficient response, and failure to use normally, so as to achieve stable motion, increase motion reliability, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below through the drawings and embodiments.

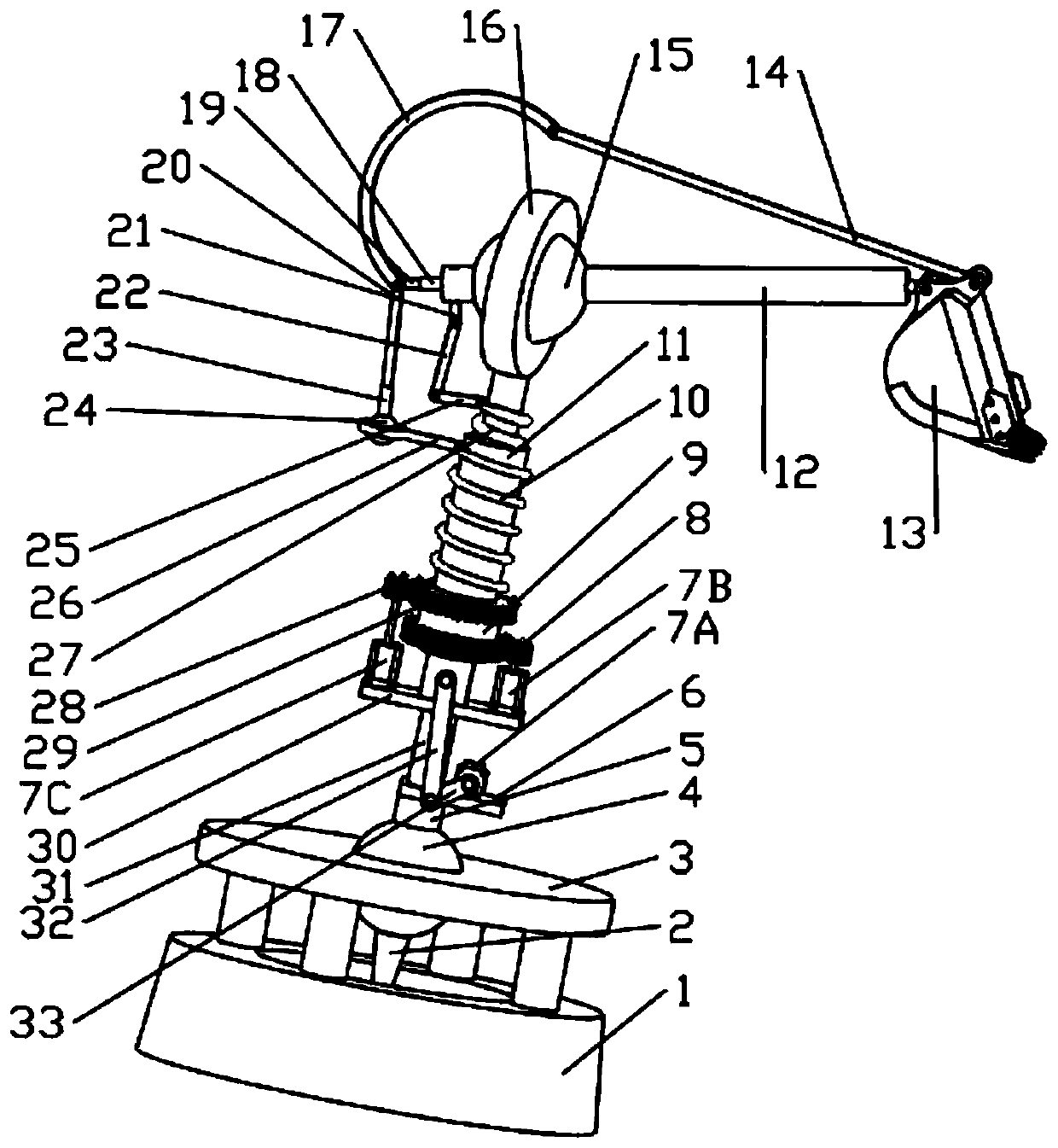

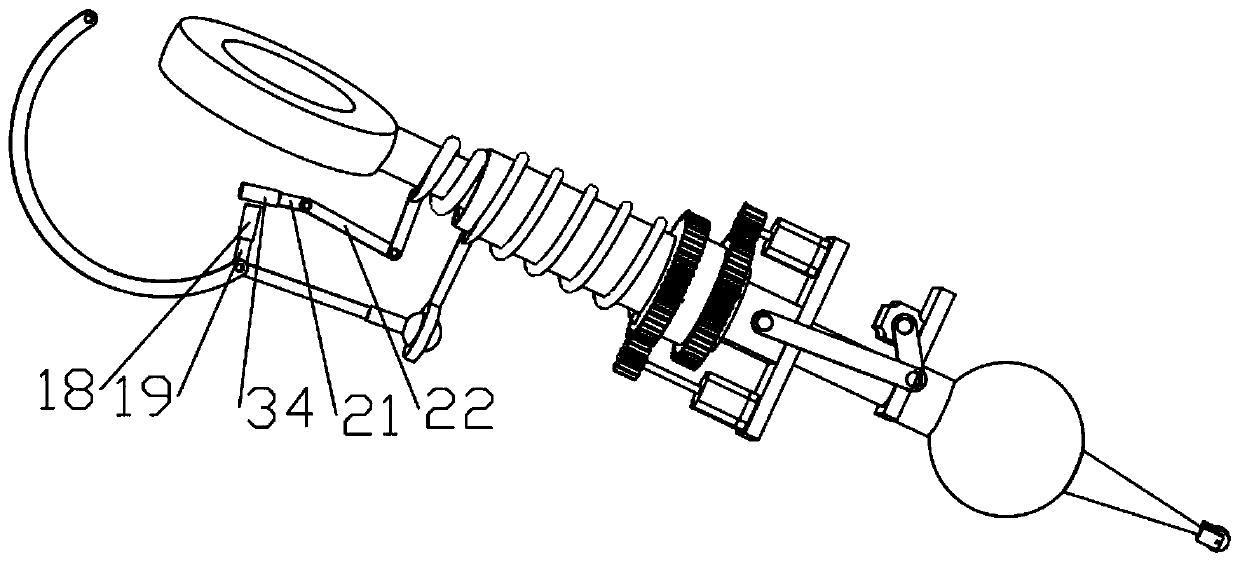

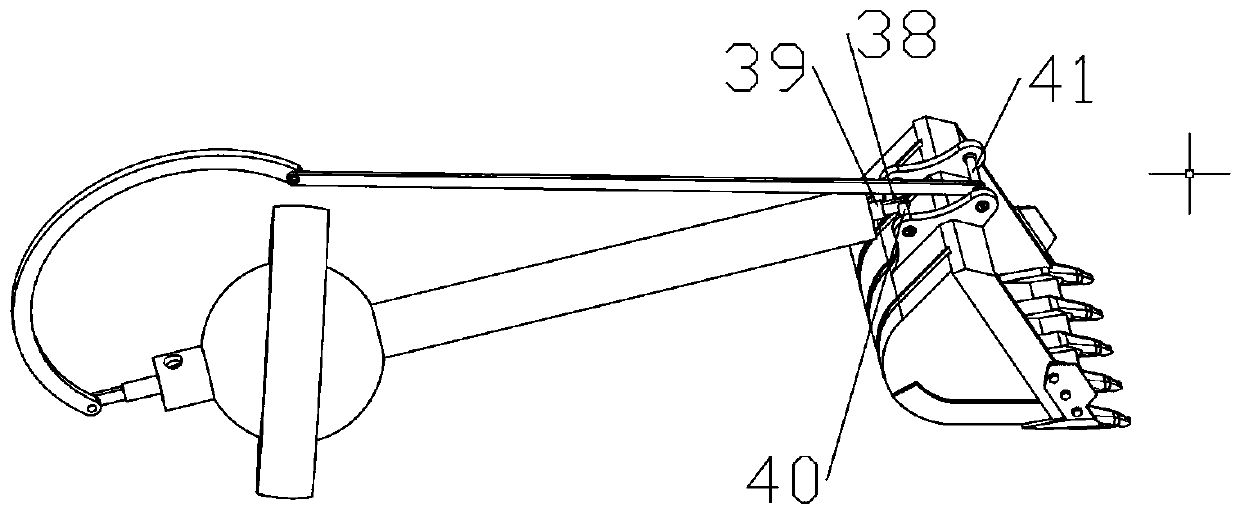

[0025] The parasitic mechanism type space controllable excavating mechanism of the present invention includes a three-dimensional rotating arm mechanism, a three-dimensional arm mechanism, a parasitic mechanism, a one-dimensional bucket mechanism and a fuselage. The specific structure and connection relationship are:

[0026] The three-dimensional rotating arm mechanism includes a power roller 35, a roller cylindrical pin 36, a roller support frame 37, a tapered connecting rod 2, a rotating arm sphere 4, a first ball ring sleeve 3, a base sleeve 5, and a first motor frame plate 6. , Rotate the arm ball rod 31, the power roller 35 is mounted on the roller cylindrical pin 36, the roller cylindrical pin 36 is mounted on the roller support frame 37, the roller support frame 37 is fixedly connected to the tapered connecting rod 2, and the tapered connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com