A Profile-Based Measurement and Positioning Method for Oil Pipe External Thread Parameters

A positioning method and parameter measurement technology, which can be applied to measurement devices, instruments, optical devices, etc., can solve the problems of poor detection accuracy, repetitive labor, and low detection efficiency, and achieve high accuracy, reduced interference, and improved positioning reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

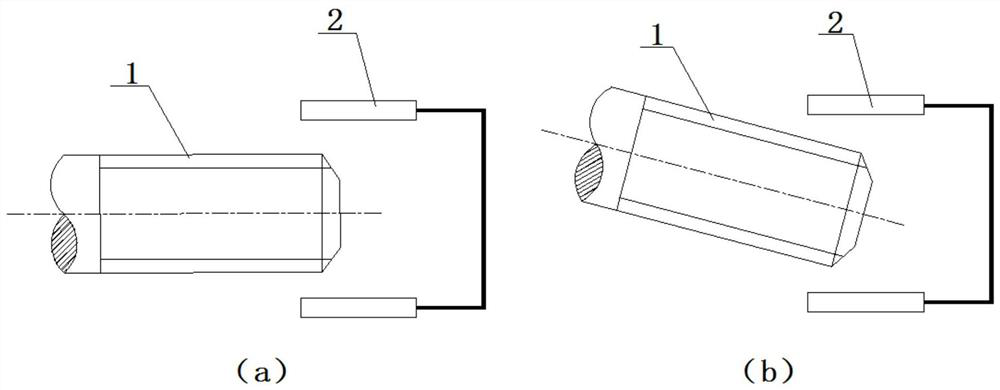

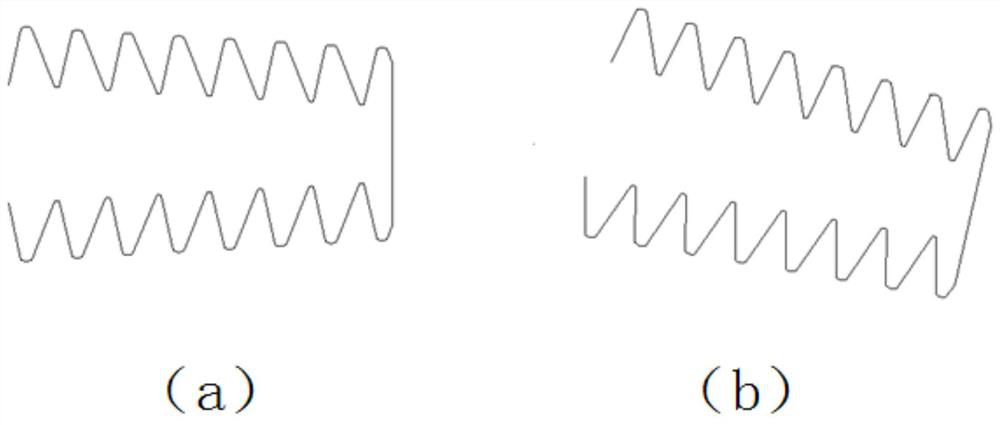

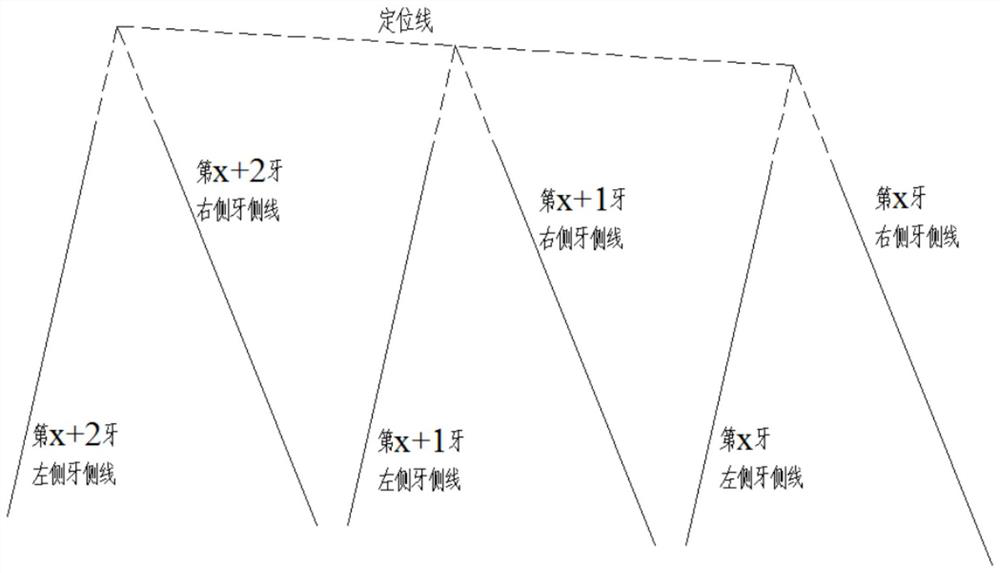

[0029] The invention provides a method for measuring and locating the external thread parameters of petroleum pipes based on contours. Firstly, a visual sensor is used to measure and determine the contours of the external threads of petroleum pipes. Measure the difference between the external thread profile and the reference profile positioning line, adjust the position of the oil pipe to be tested, and complete the positioning.

[0030] The present invention is a profile-based measurement and positioning method for oil pipe external thread parameters, using a visual sensor 2 to measure the oil pipe external thread to determine the reference profile, and then measuring the oil pipe external thread 1 to be detected, the profile of the oil pipe to be detected and the reference profile Compare the positioning line in any direction, the angle difference is the angle that needs to be adjusted in this direction of the oil pipe to be detected, and then compare the positioning line wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com