A kind of composite catalytic layer electrode for phosphoric acid fuel cell and preparation method thereof

A phosphoric acid fuel cell and composite catalytic layer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of ineffective use of catalysts, strong hydrophobicity of tetrafluoroethylene, and limited platinum utilization efficiency, and achieve increased power density , strong hydrophobicity, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

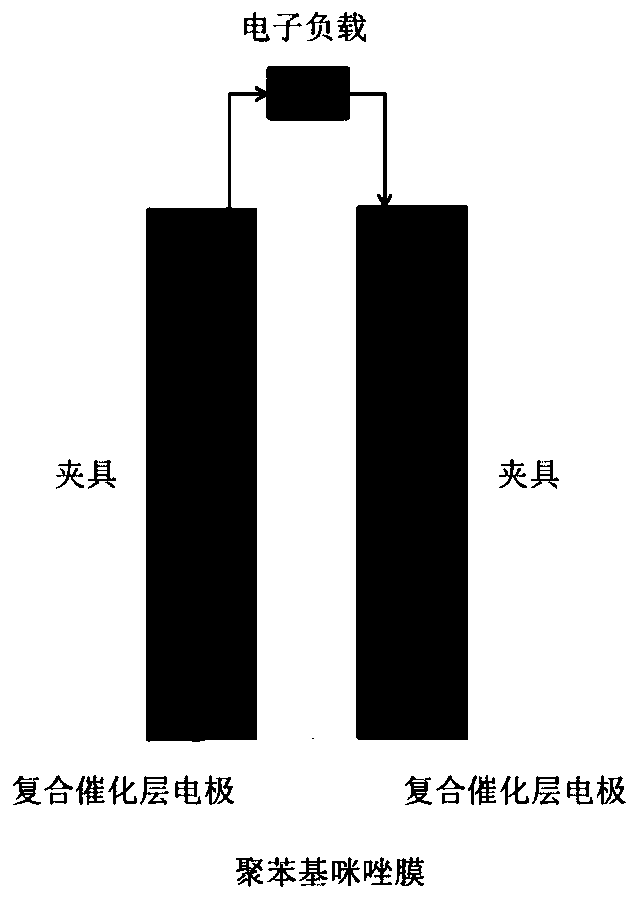

[0034] A kind of preparation method that is used for the composite catalytic layer electrode of phosphoric acid fuel cell provided by the invention, specifically comprises the following steps:

[0035] Step 1: After the electrode carrier is properly hydrophobic treated, the first layer of the composite electrode is obtained;

[0036] Step 2: After mixing the platinum carbon catalyst and the fluorine-containing hydrophobic binder in a certain proportion, apply it on the first layer of the electrode to form the second layer of the composite electrode;

[0037] Step 3: After mixing the platinum carbon catalyst and the polyphenylimidazole binder in a certain proportion, apply it on the second layer of the composite electrode to form the third layer of the composite electrode;

[0038] Step 4: Sintering the above-mentioned electrodes at high temperature to obtain composite catalytic layer electrodes for phosphoric acid fuel cells;

[0039] According to the present invention, the e...

Embodiment 1

[0046] First take an area of 10cm 2 Porous carbon paper (3.33cm×3.33cm), washed with ethanol and water, and dried. The polytetrafluoroethylene material is an emulsion dispersion and shaken fully, and the carbon paper is soaked in the polytetrafluoroethylene emulsion for 1 hour, then taken out to dry, and then weighed. Repeat the above steps 3 times until the weight ratio of carbon paper to polytetrafluoroethylene reaches 100:20, and sinter at 300°C for 1 hour to obtain the first layer of substrate.

[0047] Take 5 mg of platinum-carbon catalyst (40% platinum loading) and mix it with 0.01 mL of polyvinylidene fluoride dispersion with a mass fraction of 5% by ultrasonic at room temperature, take 5 mL of dimethylformamide as a solvent, and mix by ultrasonic for 1 to 2 hours . Then add 1 mL of auxiliary agent in 20% ethanol aqueous solution, and continue to sonicate for 1 to 2 hours. The mass ratio of the platinum carbon catalyst to polyvinylidene fluoride solid solution is 1...

Embodiment 2

[0052] First take an area of 10cm 2 Porous carbon paper (3.33cm×3.33cm), washed with ethanol and water, and dried. The polytetrafluoroethylene material is an emulsion dispersion and shaken fully, and the carbon paper is soaked in the polytetrafluoroethylene emulsion for 2 hours, then taken out to dry, and then weighed. Repeat the above steps three times until the weight ratio of carbon paper to polytetrafluoroethylene reaches 50:20, and sinter at 300°C for 2 hours to obtain the first layer of substrate.

[0053] Take 1 mg of platinum-carbon catalyst (40% platinum loading) and mix it with 0.004 mL of polyvinylidene fluoride dispersion with a mass fraction of 5% by ultrasonic at room temperature, take 5 mL of dimethylformamide as a solvent, and mix by ultrasonic for 1 to 2 hours . Then add 1 mL of auxiliary agent in 20% ethanol aqueous solution, and continue to sonicate for 1 to 2 hours. The mass ratio of the platinum carbon catalyst to the polyvinylidene fluoride solid sol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap