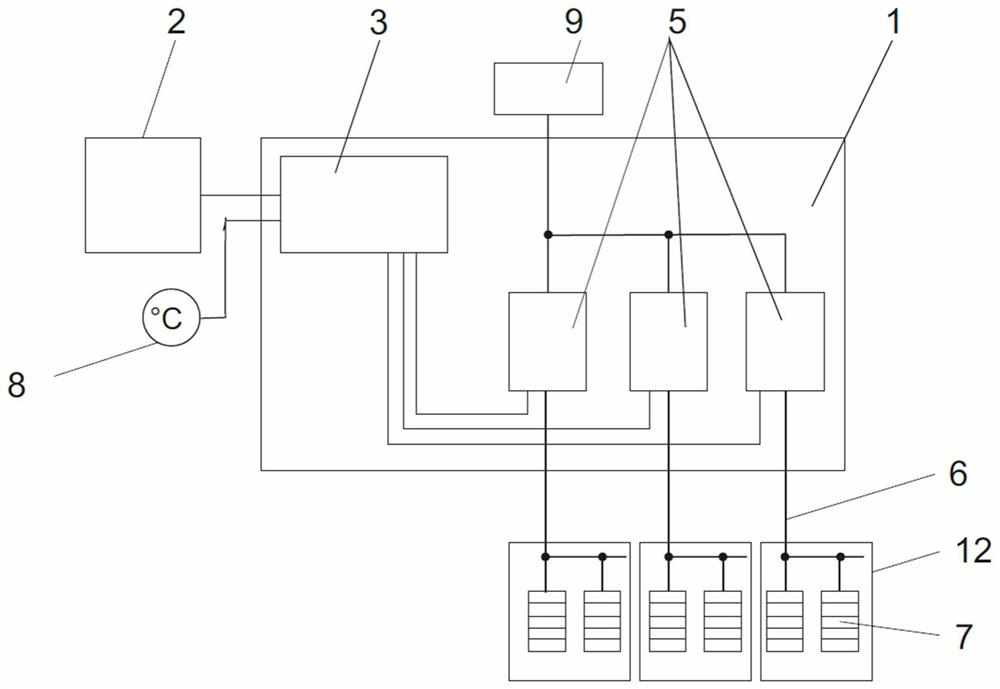

Method and device for energy management of an electrically heated turnout snow melting system

An energy management and electric heating technology, applied in the field of energy management, can solve the problems of delayed heating, energy consumption and insufficient heating in the heating system, and achieve the effects of avoiding power peaks, saving energy, and reducing energy supply costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

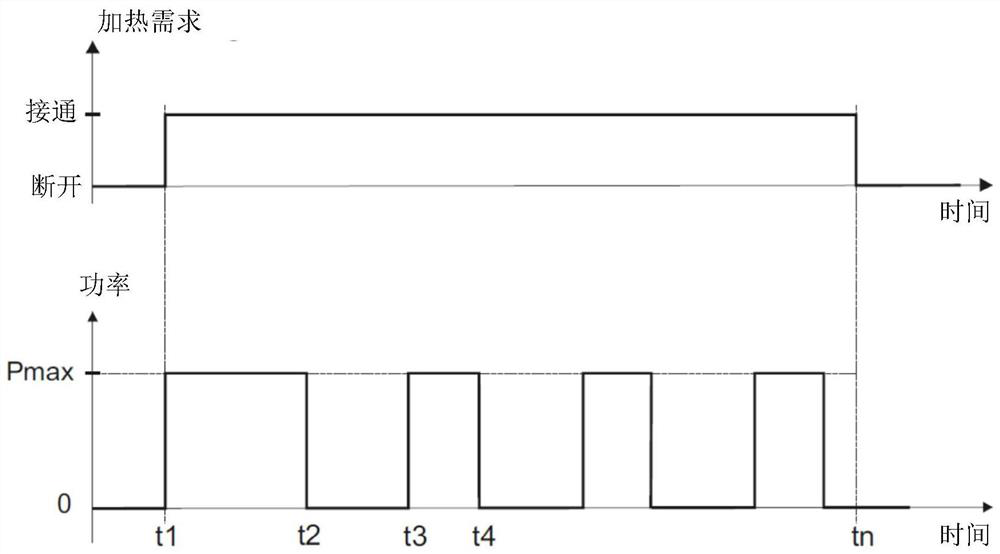

[0091] In heating operation over a plurality of cycle times Zt, when the power ratio L is the same, the power corresponds to the product of the power ratio L and the installed connected load P of all heating elements 7 of the electrically heated point snow melting system.

[0092] The term "power ratio" will be explained in more detail below.

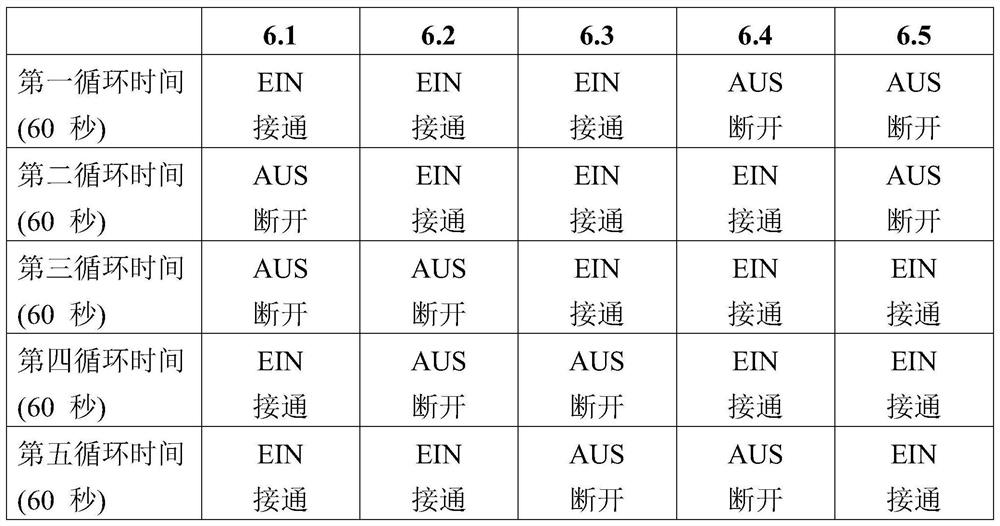

[0093] The maximum number of power ratios L is produced by reducing the number of heating output circuits 6 of the electric heating switch snow melting system by one. However, this maximum number is limited at power ratios of less than about 35% because the switches 12 are heated very little and for economical reasons in electrically heated switch snowmelting systems with more than 15 switches 12 .

[0094] The power ratio L can be switched during heating operation. The syntax of the power ratio L is derived from the duty cycle of the heating time and cooling time.

[0095] For all heating output circuits 6 of the electric heating tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com