Long-handled almond peach harvesting device and harvesting method thereof

A long-handled almond and almond technology, which is applied to a long-handled almond harvester and the field of its harvesting, can solve the problems of large workload, low harvesting efficiency, and difficulty in harvesting long-handled almonds, thereby improving work efficiency. , the effect of high harvesting efficiency and saving labor resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

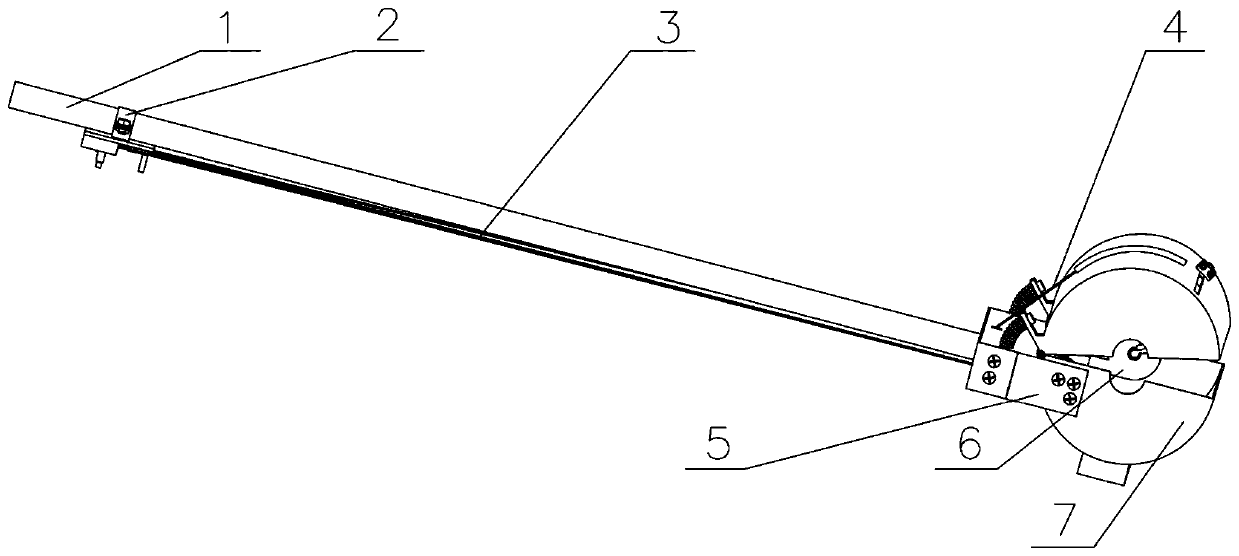

[0031] Long handle almond harvester of the present invention such as figure 1 As shown, it mainly includes a handle 1, a hand-operated device 2, a transmission rope 3, a pull cord 4, a transmission system 5, a cutter system 6 and a fruit collection device 7. Cutter system 6 and fruit collecting device 7 are installed in handle 1 front end, and hand-operated device 2 is installed in handle 1 afterbody.

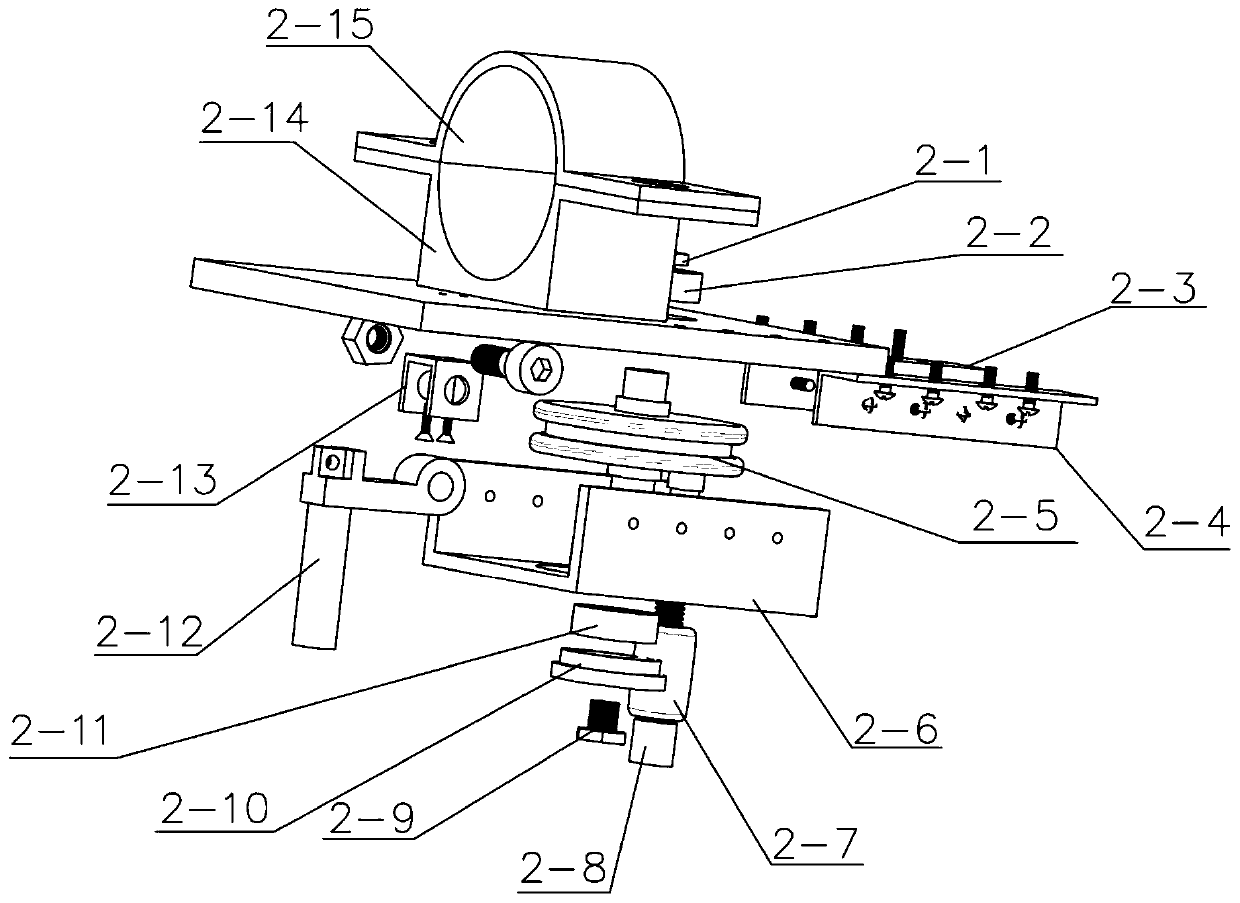

[0032] Hand-operated device 2 is the main operation part, the power source of the whole harvester work, such as figure 2 As shown, it includes bolt 1 2-1, bearing 1 2-2, housing fixing bracket 1 2-3, housing fixing bracket 2 2-4, wheel shaft 2-5, hand-cranking device housing 2-6, and rocking handle 2-7 , Internal thread cap 2-8, bolt 2 2-9, fixed base 2-10, bearing 2 2-11, handle 2-12, handle bracket 2-13, lower fastener 2-14, upper fastener ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap