Gear rack pair flapping wing driving mechanism based on externally-meshed planetary gear reducer

A technology of gear reducer and rack and pinion, which is applied in the field of miniature flapping wing aircraft, can solve the problems of insufficient flight stability and reliability, and achieve the effects of high efficiency and smooth transmission process, low transmission noise and high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

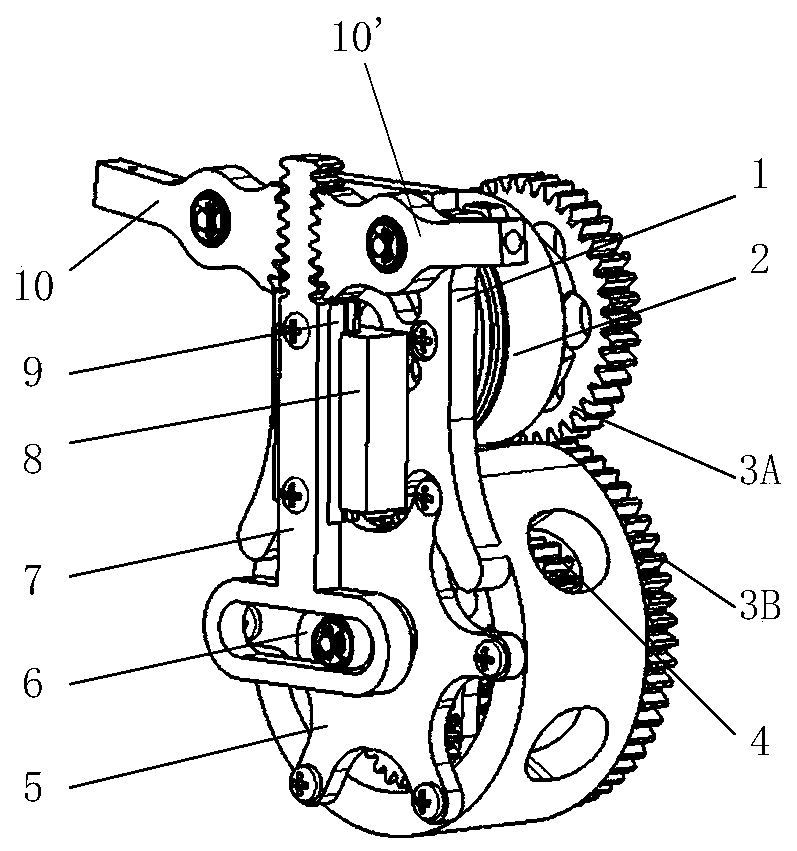

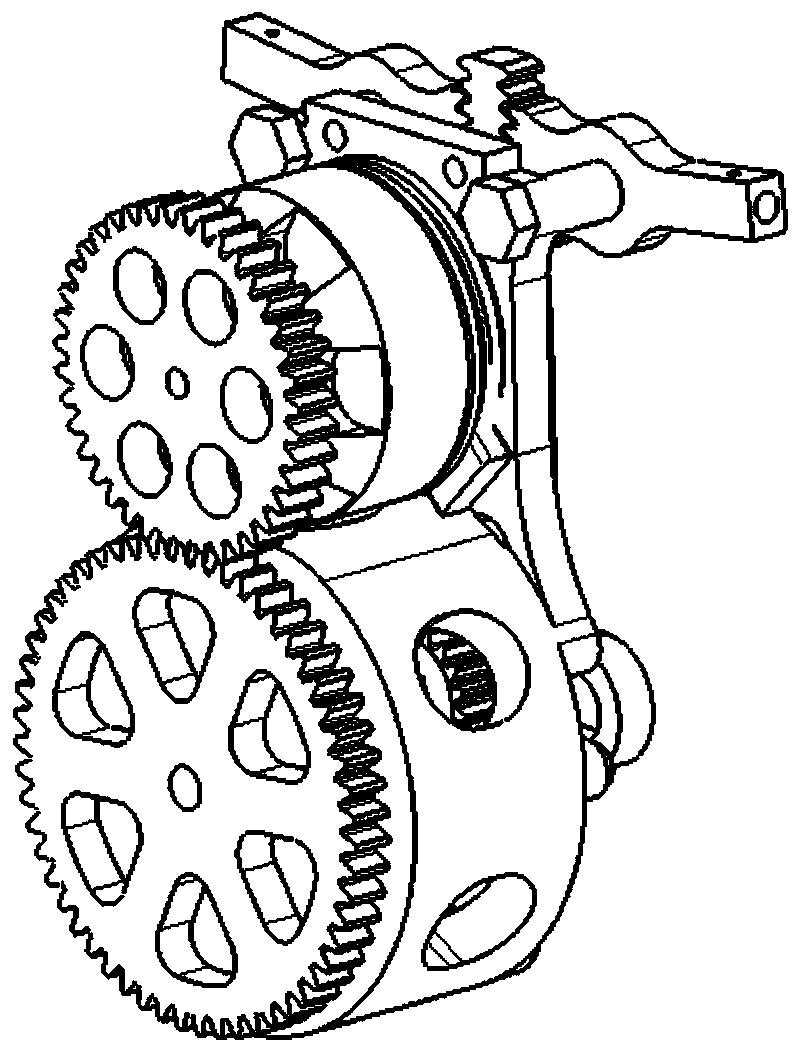

[0031] The invention is based on the rack and pinion flapping wing driving mechanism of the external meshing planetary gear reducer, which includes a frame, a motor, a parallel gear reducer, an external meshing planetary gear reducer and a connecting rod rocker mechanism.

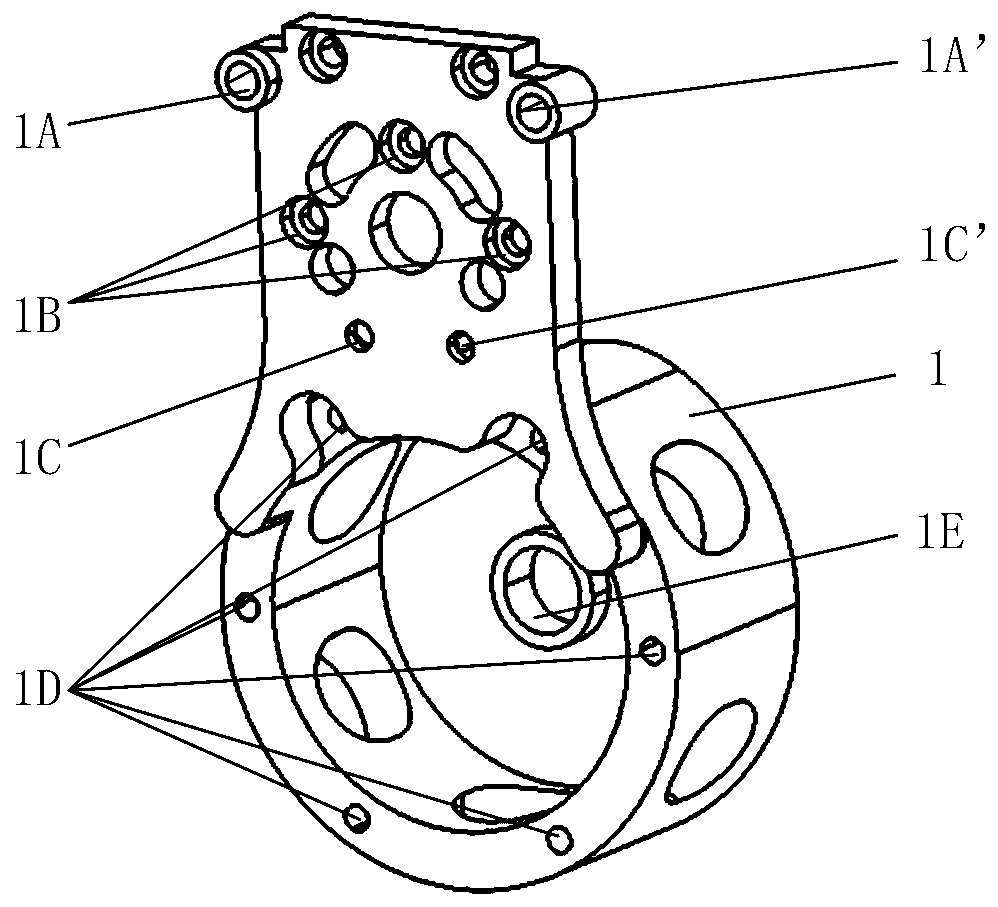

[0032] The frame 1 is left-right symmetrical as a whole, and the direction facing the machine nose is regarded as the front end. Frame 1 is provided with two fixing holes, two rocker shaft holes 1A, 1A', three motor mounting holes 1B, two limit block mounting holes 1C, 1C', and six cover plates from top to bottom. The installation hole 1D and a transmission shaft hole 1E, except the cover plate installation hole, all the holes pass through front and back, and the holes are symmetrically arranged and the axes are all parallel.

[0033] The two fixing holes at the top of the frame 1 are used to install the driving mechanism on the aircraft fuselage by means of threaded connection. The two rocker shaft holes ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap