A Closed Bearing Lubricating Oil Status and Bearing Fault Online Monitoring System

A monitoring system and lubricating oil technology, applied in the direction of shafts and bearings, bearing components, bearing assembly, etc., can solve problems such as dust mixing, reduced bearing lubrication efficiency, and lubricating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

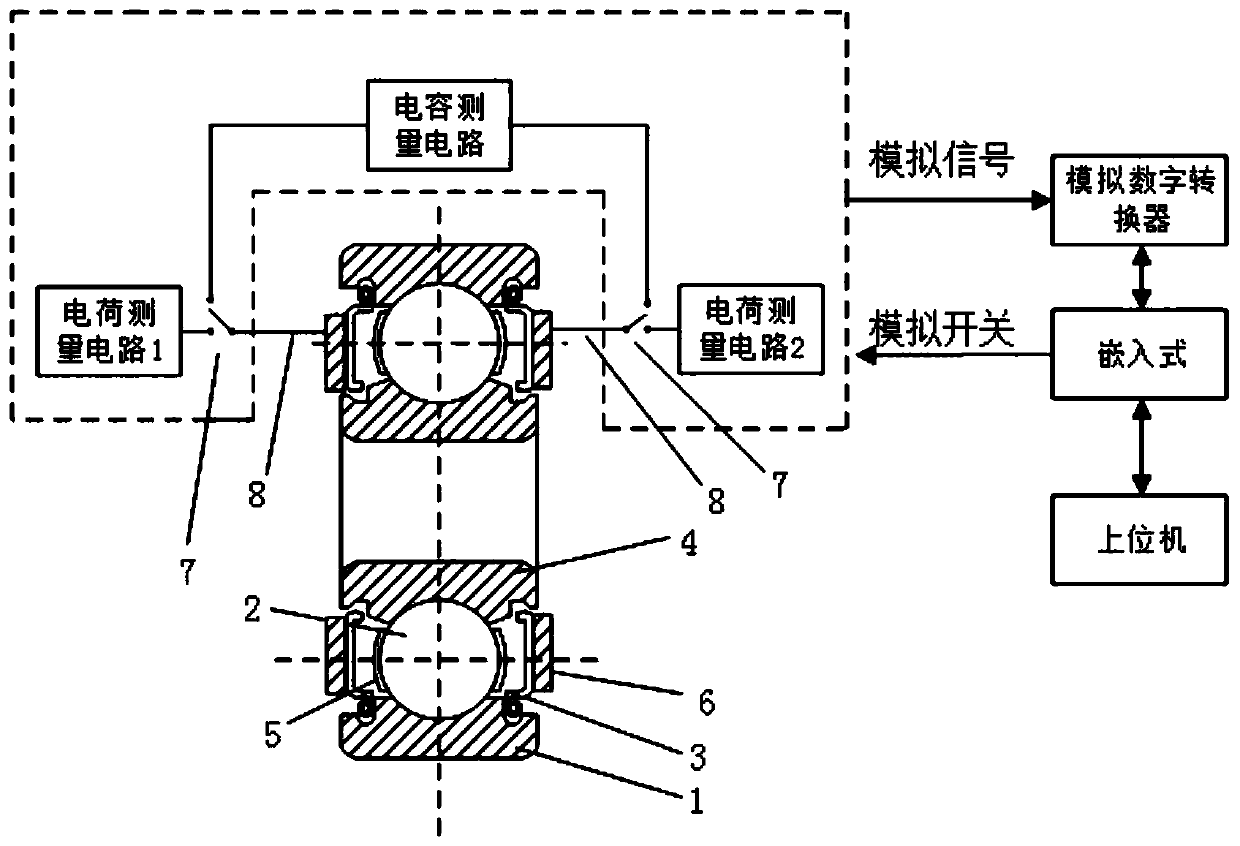

[0018] see figure 1 , an on-line monitoring system for lubricating oil status and bearing faults of closed bearings, including two sealing rings 3 at both ends of the bearing that can be used as polar plates, and the types of bearings include sliding bearings, joint bearings, rolling bearings and deep groove ball bearings. The outer material of the sealing ring 3 is non-metal, which can avoid equipotential electrical connection with the bearing.

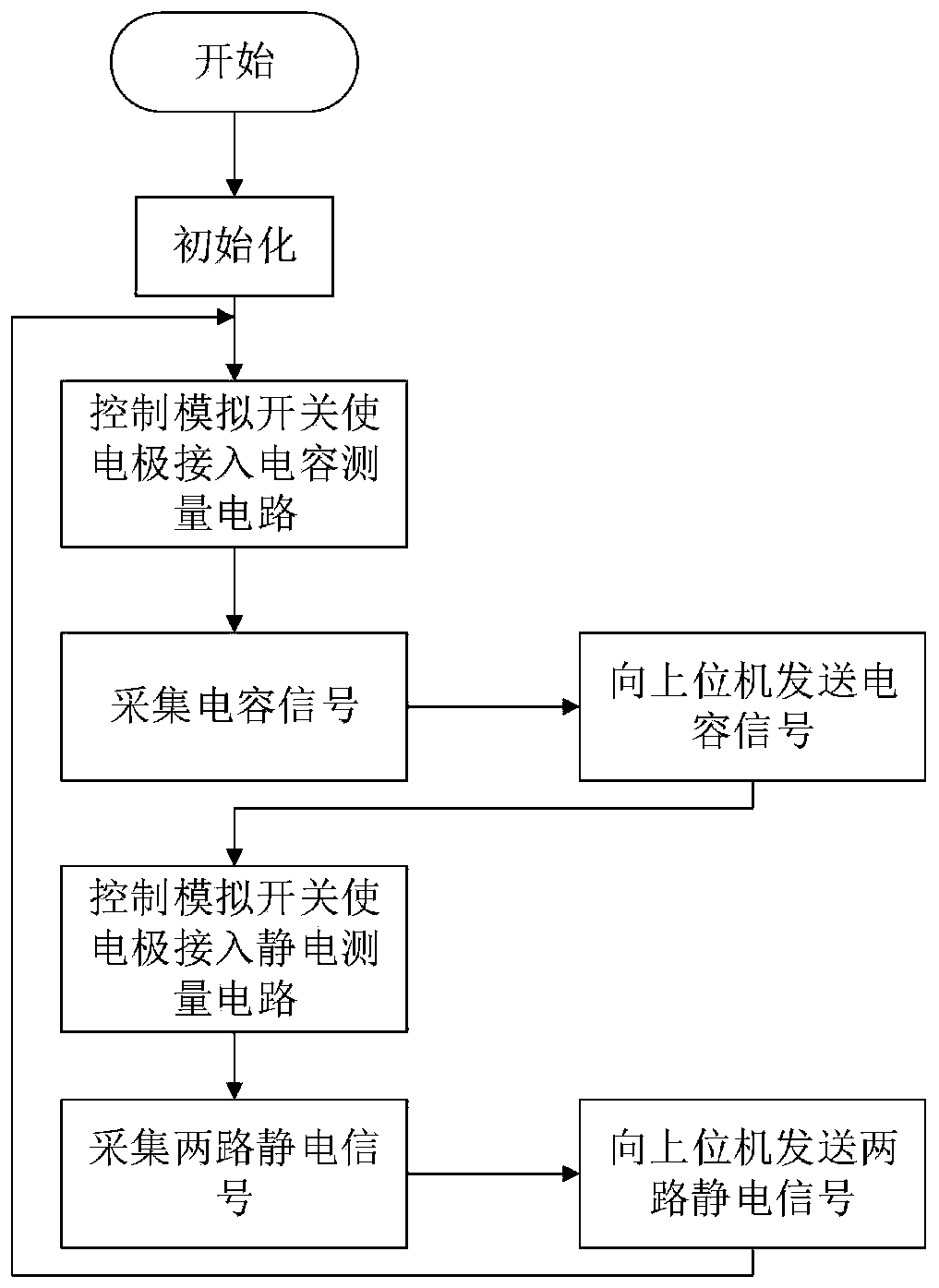

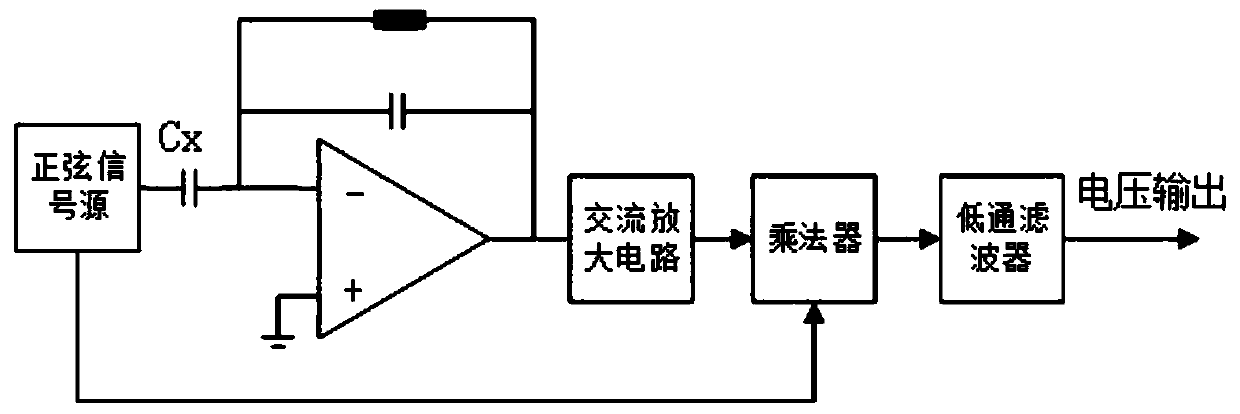

[0019] Connect and lead wire 8 on sealing ring 3, two sealing rings 3 connect an analog switch 7 through wire 8 respectively, two analog switches 7 connect a capacitance measuring circuit and two independent charge measuring circuits together, through analog switch 7 The control plate is connected to a specific circuit to obtain the capacitance value when the two plates form a capacitive structure and the two elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com