Gyroscope structure

A gyroscope and mass block technology, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., to achieve the effect of convenient design, improved sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the gyroscope structure provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

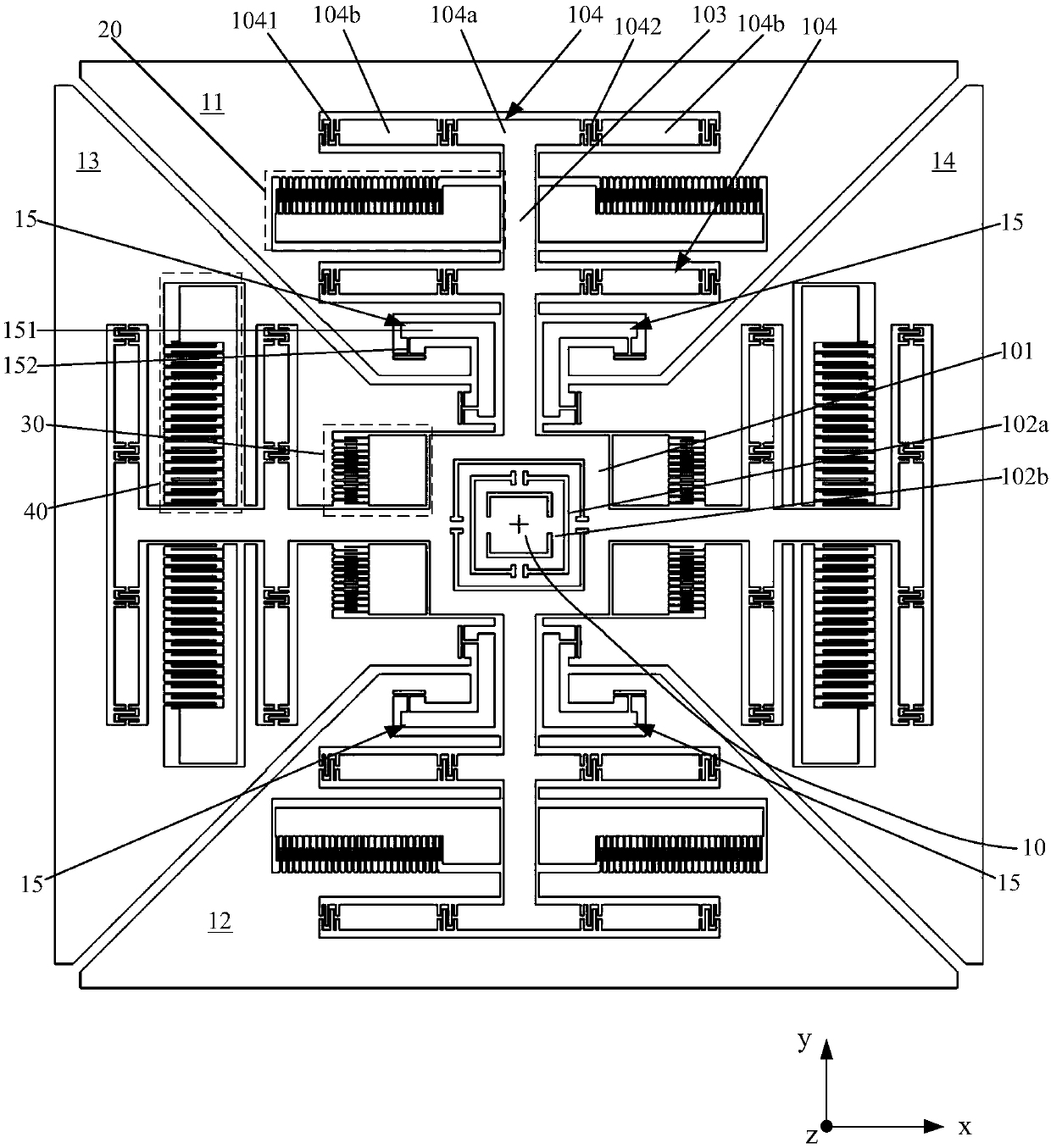

[0029] Please refer to figure 1 , is a structural schematic diagram of a gyroscope structure according to a specific embodiment of the present invention.

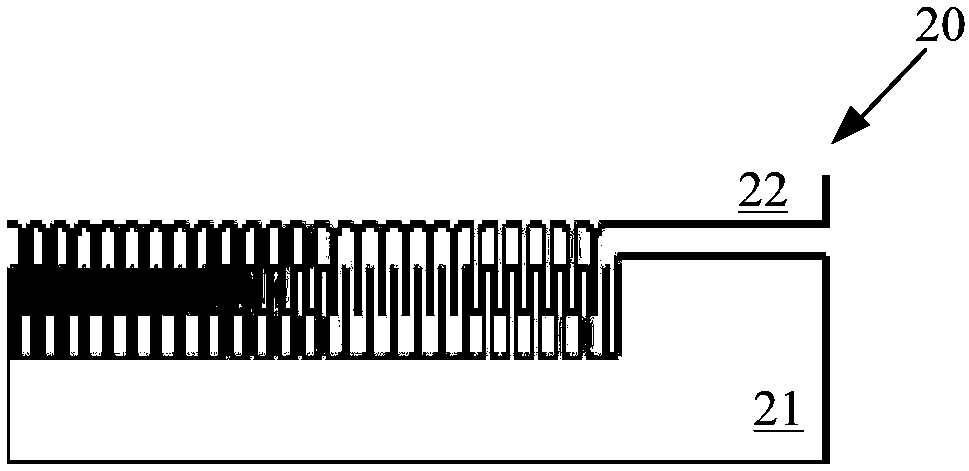

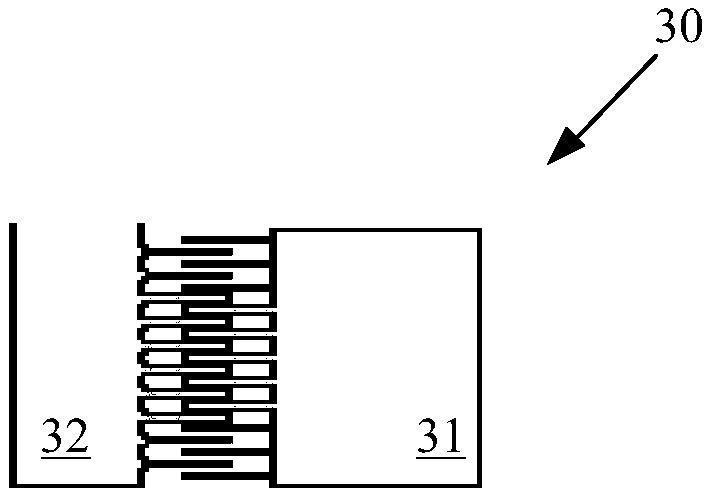

[0030] The gyroscope includes: a substrate (not shown in the figure), an anchor point 10 fixed on the substrate, a plurality of mass blocks suspended on the substrate around the anchor point, including: a first mass Block 11, second mass block 12, third mass block 13 and fourth mass block 14, the plurality of mass blocks are respectively connected to the anchor point 10 through elastic connection components; the first mass block 11, the second mass block The mass blocks 12 are arranged oppositely in the first direction, and are used to make the first mass block 11 and the second mass block 12 perform translational reciprocating motion along the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com