Frequency-adjustable local resonance structure unit for constructing acoustic metamaterials

A technology of acoustic metamaterials and local resonance, which is applied in the field of acoustic metamaterials, can solve problems such as the difficulty of adjusting the resonance frequency, and achieve the effect of overcoming the difficulty of adjusting the resonance frequency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

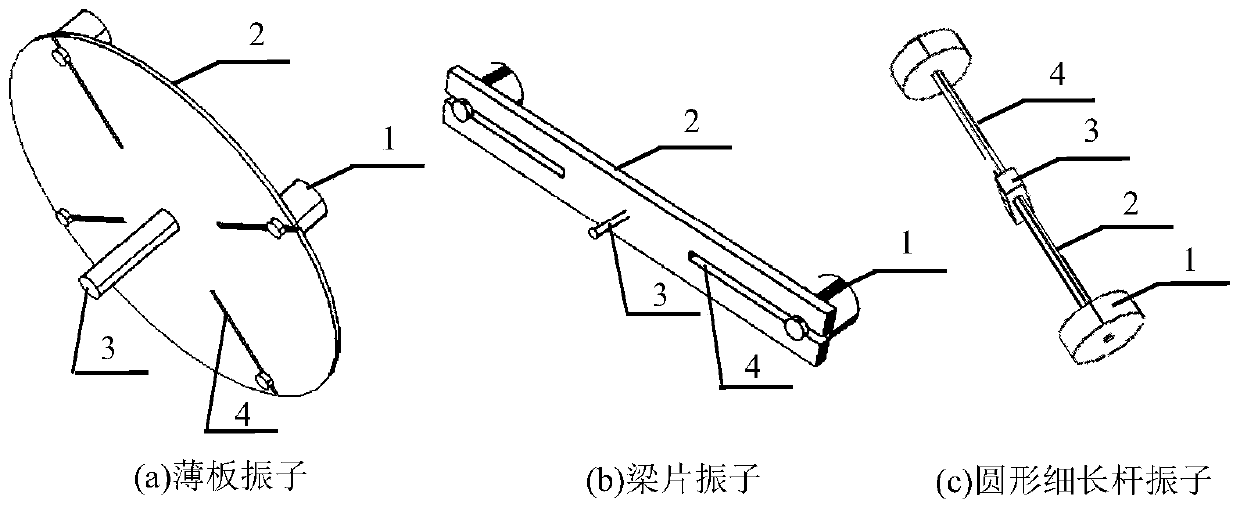

Embodiment 1

[0027] The local resonance unit adopts the form of a single vibrator. The vibrator stiffness structure 2 is a rectangular thin-layer beam whose length, width, and thickness are 130mm×12mm×2mm. The length, width and thickness of each chute are 50mm×3mm×2mm; the supporting structure 3 supports the vibrator stiffness structure 2 in the middle support, and the single weight of the vibrator mass structure 1 is 13g, and the vibrator mass structure 1 is installed on the vibrator stiffness In the chute at a distance of 30mm from the support point on structure 2; the vibrator quality structure 1 is made of steel, the vibrator stiffness structure 2 is made of aluminum, and the support structure 3 is made of PVC.

Embodiment 2

[0029] The other parameters of the second embodiment are the same as those of the first embodiment. The only difference is that in the second embodiment, the vibrator mass structure 1 is installed in the chute on the vibrator stiffness structure 2 at a distance of 40 mm from the support point.

Embodiment 3

[0031] The other parameters of the third embodiment are the same as those of the first embodiment, except that in the third embodiment, the vibrator mass structure 1 is installed in the chute on the vibrator stiffness structure 2 at a distance of 50 mm from the support point.

[0032] In the present invention, preferably, the resonant frequency of the structural unit in Embodiment 1 is 289 Hz, the resonant frequency of the structural unit in Embodiment 2 is 211 Hz, and the resonant frequency of the structural unit in Embodiment 3 is 159 Hz. The results show that the resonant frequency of the local resonance unit can be flexibly changed by adjusting the position of the vibrator mass structure 1 on the vibrator stiffness structure 2 along the adjustment device 4 without changing the original structure and material parameters; Compared with the local resonance structural unit, the frequency-tunable local resonance structural unit designed by the present invention for the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com