Linear motor system

A linear motor, electromagnetic coil technology, applied in the direction of propulsion system, electrical components, electromechanical devices, etc., can solve problems such as flexibility limitation, and achieve the effect of reducing effect and interference, low cost and low inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

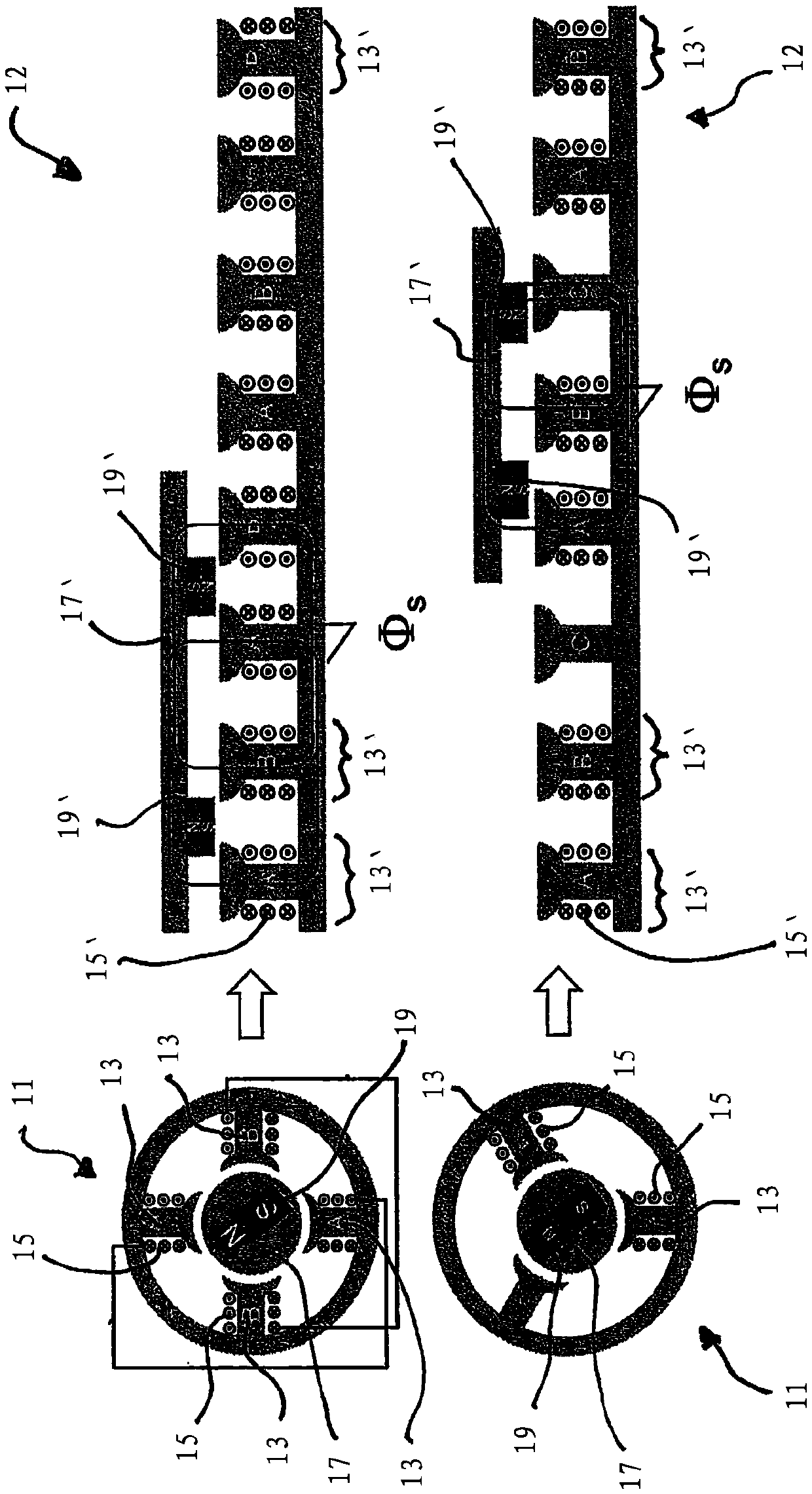

[0049] figure 1 On the left are shown two conventional electric machines 11 , each comprising four or three stator elements 13 with respective electromagnetic coils 15 and a rotor 17 with permanent magnets 19 . A magnetic flux in the electric machine 11 is formed by the magnetic coil 15 when current flows through it. The magnetic flux interacts with the permanent magnets 19 of the rotor 17 and thereby causes the rotor 17 to rotate.

[0050] exist figure 1 On the right, a conventional electric motor 12 is respectively formed as a linear motor system 12 according to the prior art. The stator element 13' of the linear motor system 12 corresponds to the stator element 13 of the motor 11, and the rotor 17' of the linear motor system 12 with two permanent magnets 19' corresponds to the rotor 17 of the motor 11 with permanent magnets 19, respectively. The stator elements 13 of the electric motor 11 thus spread out to a certain extent in a linear direction, and the stator elements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com