3D (Three Dimensional) printing equipment for printing artificial heart and bionic construction method of artificial heart

A technology of 3D printing and construction method, which is applied in processing and manufacturing, manufacturing auxiliary devices, medical science, etc., can solve the problems of no reference group, making a single normal biological sample, and the singleness of experiment or operation results, so as to ensure the safety of the experiment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

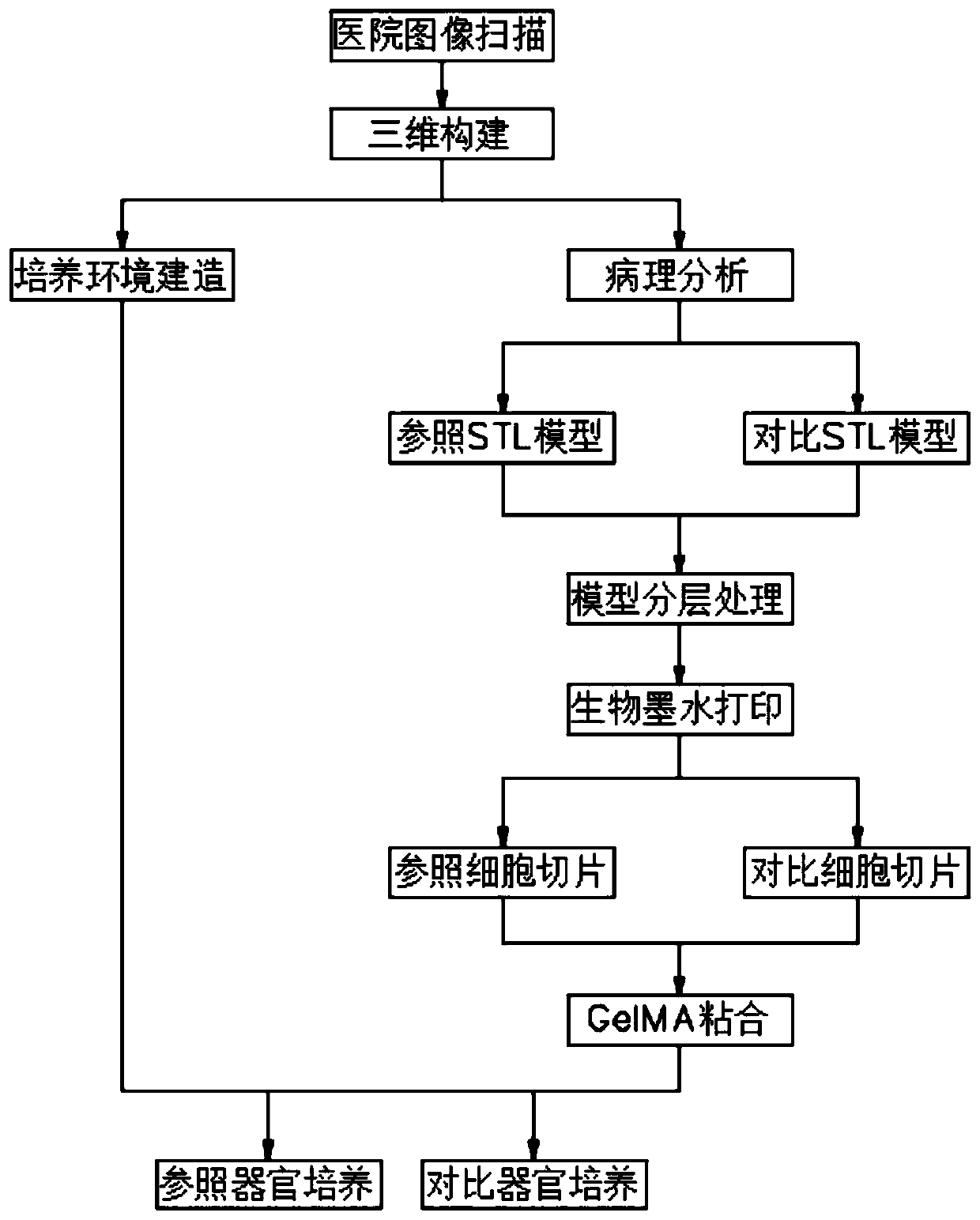

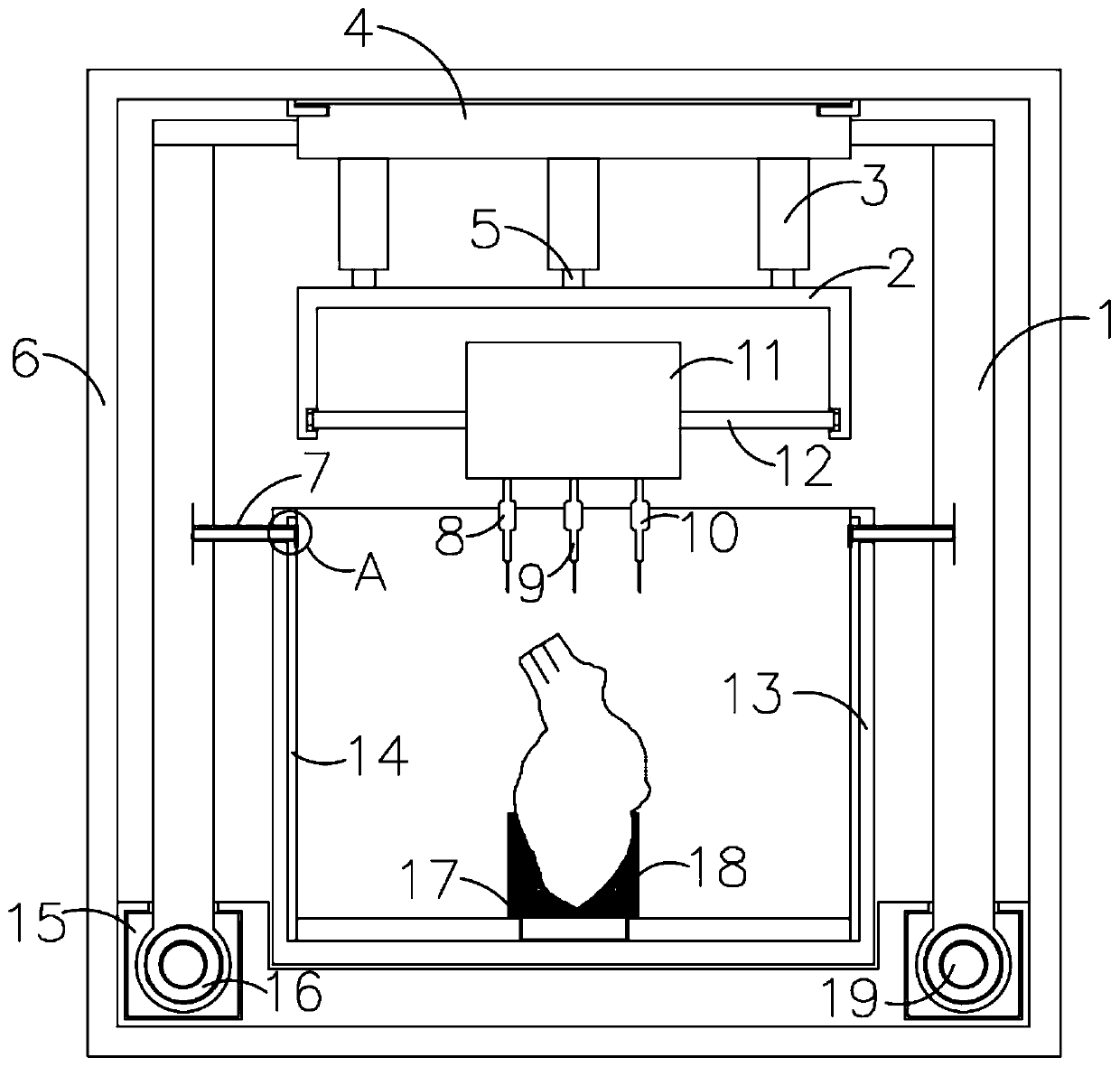

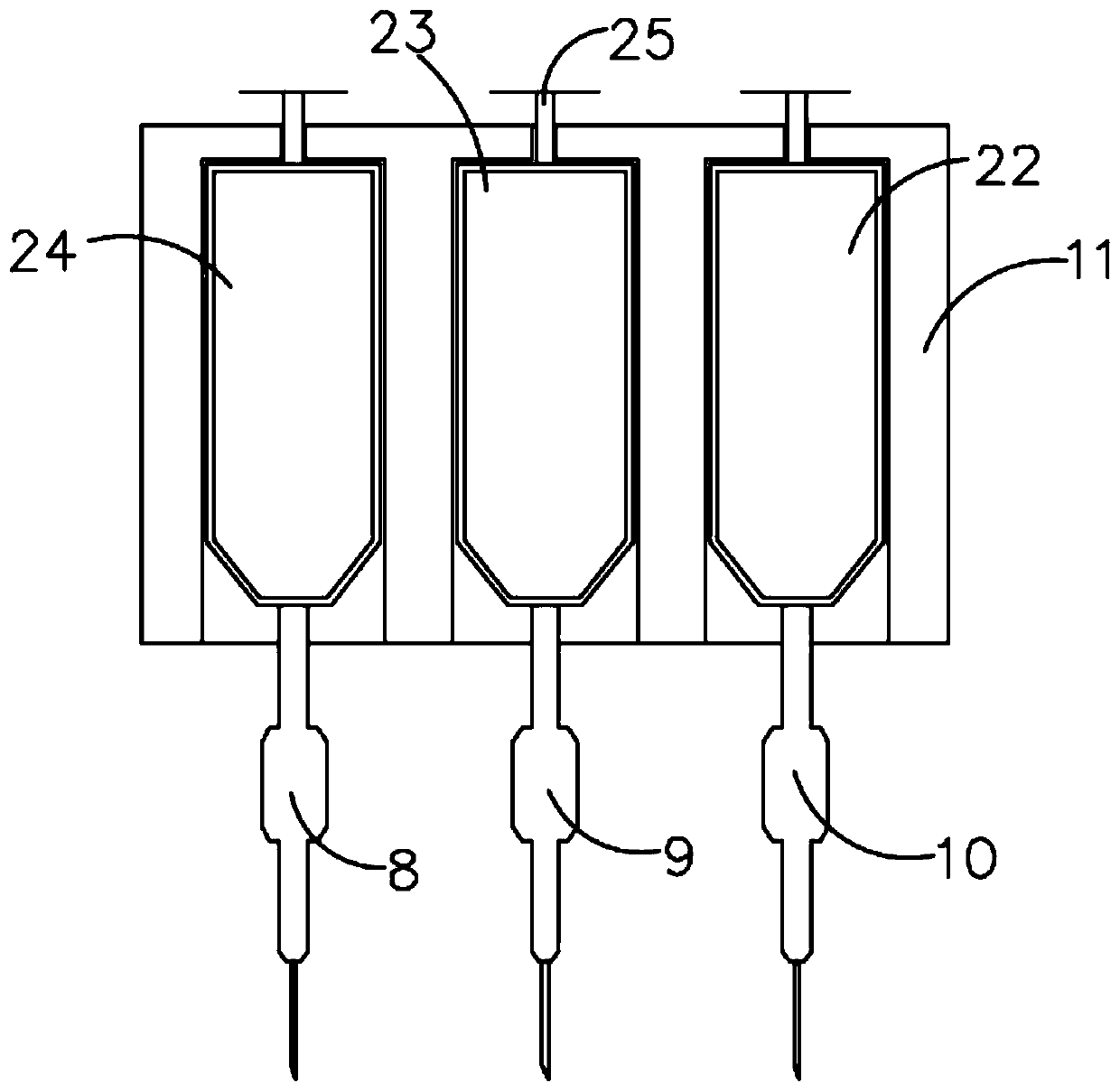

[0031] Artificial organs take the artificial heart as an example, refer to Figure 1-5 , a 3D printing device for artificial organ printing, comprising a 3D bioprinter 6, a solution tank 13 is installed in the 3D bioprinter 6, a sliding mechanism is arranged in the 3D bioprinter 6, and the sliding mechanism is slidably connected to the inner wall of the 3D bioprinter 6, A plurality of cylinders 3 are installed on the sliding structure, and the driving end of the cylinder 3 is fixedly connected with a telescopic shaft 5, and the end of the plurality of telescopic shafts 5 away from the cylinder 3 is fixedly connected with a fixed frame 2, and the fixed frame 2 is rotatably connected with a first ball wire Rod 12, the first ball screw rod 12 is slidably connected with a printing driver 11, a moving mechanism is installed in the printing driver 11, and a gel storage box 24, a tissue cell storage box 23 and a stem cell storage box are arranged in the printing driver 11 22. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com