Universal type cylindrical workpiece machining tooling

A general-purpose, cylindrical technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of increased processing costs, poor generality of processing tooling, etc., to improve work efficiency, good versatility, and reduce processing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

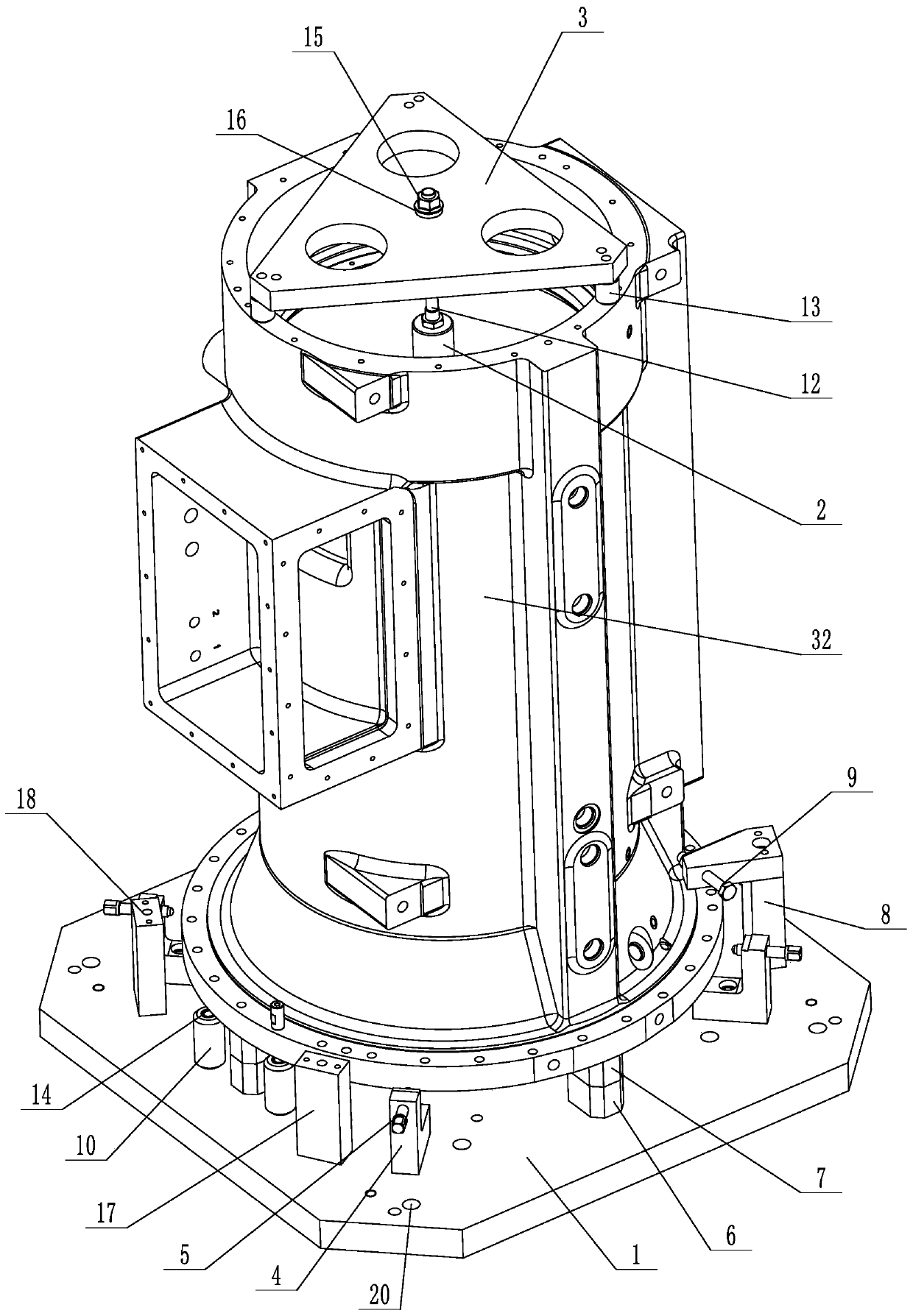

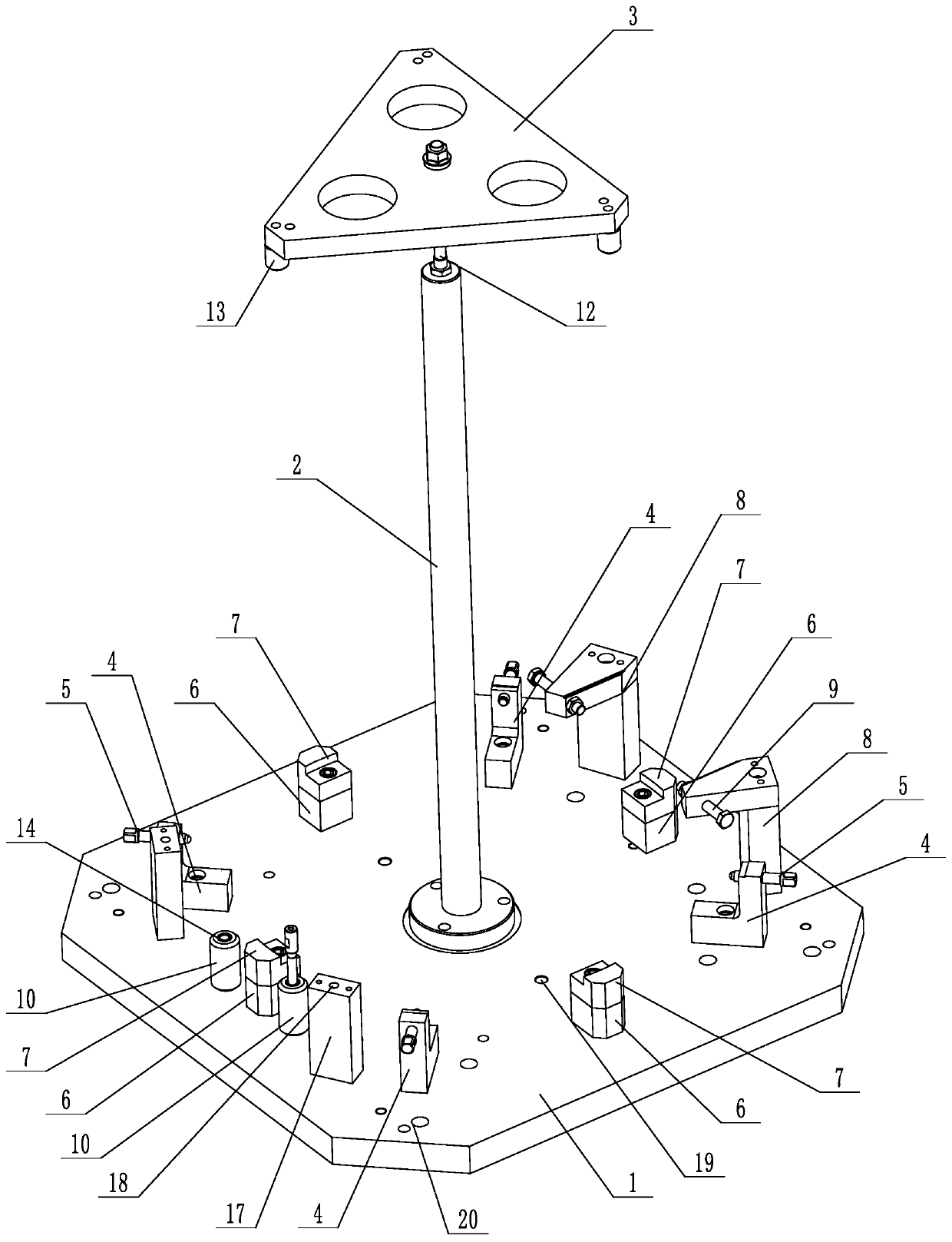

[0027] Example 1: A universal cylindrical workpiece processing tool (see attached figure 1 , attached figure 2 ), including the base 1, the positioning column 2, the pressure plate 3, the lower end of the positioning column is connected to the base, the base is rectangular, the corners of the base are installed with side top blocks 4, and the side top blocks are connected with the thread set radially toward the positioning column The top rod 5, the positioning support base 6 is installed between the adjacent top blocks on both sides, the support block 7 is detachably installed on the positioning support base, and the positioning support block on one side of the base is installed with an inverted L-shaped positioning top block on both sides. 8. The positioning top block is threadedly connected to the positioning top rod 9, and the two positioning top rods are set opposite each other. The positioning support seat on the other opposite side of the base is equipped with support c...

Embodiment 2

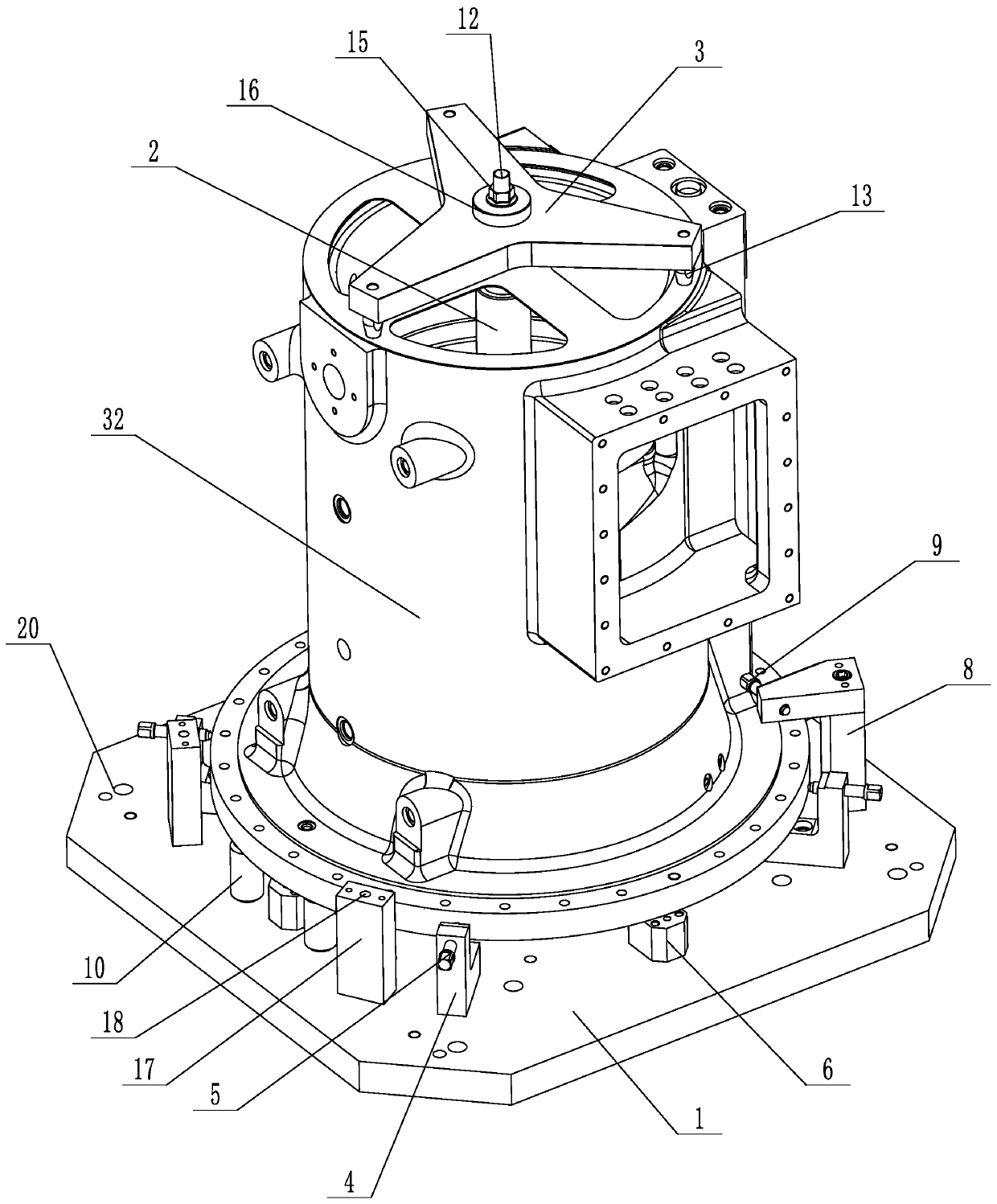

[0029] Example 2: A universal cylindrical workpiece processing tool (see attached image 3 , attached Figure 4), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the pressure plate has a Y-shaped structure, three pressure arms 21 are evenly distributed on the pressure plate, and a pressure plate support foot is installed at the end of the pressure arm. The lower part of the upper pressing plate of the locking rod is sleeved with a template 22 which is adapted to the upper end of the cylindrical workpiece. The template is provided with a positioning through hole 23 corresponding to the supporting foot of the pressing plate. positioned in the through hole. The other structures are the same as those of Embodiment 1.

[0030] When the cylinder workpiece is processed with or without vertical lathe, the support block is removed from the positioning support seat, the lower end of the cylinder workpiece is supported on the support sc...

Embodiment 3

[0031] Example 3: A universal cylindrical workpiece processing tool (see attached Figure 5 , attached Image 6 ), its structure is similar to Embodiment 1, the main difference is that in this embodiment, three radially arranged chute 24 are evenly arranged on the pressure plate, an annular groove 25 is arranged in the middle of the pressure plate, the chute and the annular groove pass through, and the bottom surface of the annular groove The middle position is provided with a stud 26, the stud is connected with a threaded sleeve 27, and the outer wall of the threaded sleeve is provided with a push block 28 in one-to-one correspondence with the chute, and the distance between the outer wall of the push block and the axis of the stud is clockwise or counterclockwise. The direction gradually increases, a self-centering rod 29 is installed in the chute, one end of the self-centering rod extends out of the chute and abuts on the outer wall of the screw sleeve, and a positioning sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com