Vehicle Air Suspension System

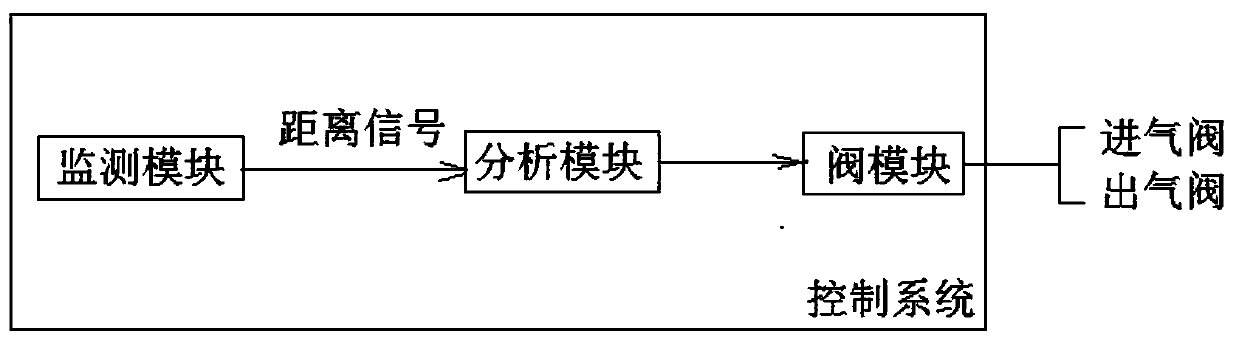

A technology for air suspension and vehicles, which is applied to suspensions, elastic suspensions, vehicle components, etc. It can solve the problems of excessive instantaneous impact of air springs, high pressure of air springs, and complicated arrangement, so as to prevent failure and extend service life Lifespan, the effect of buffering momentary pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

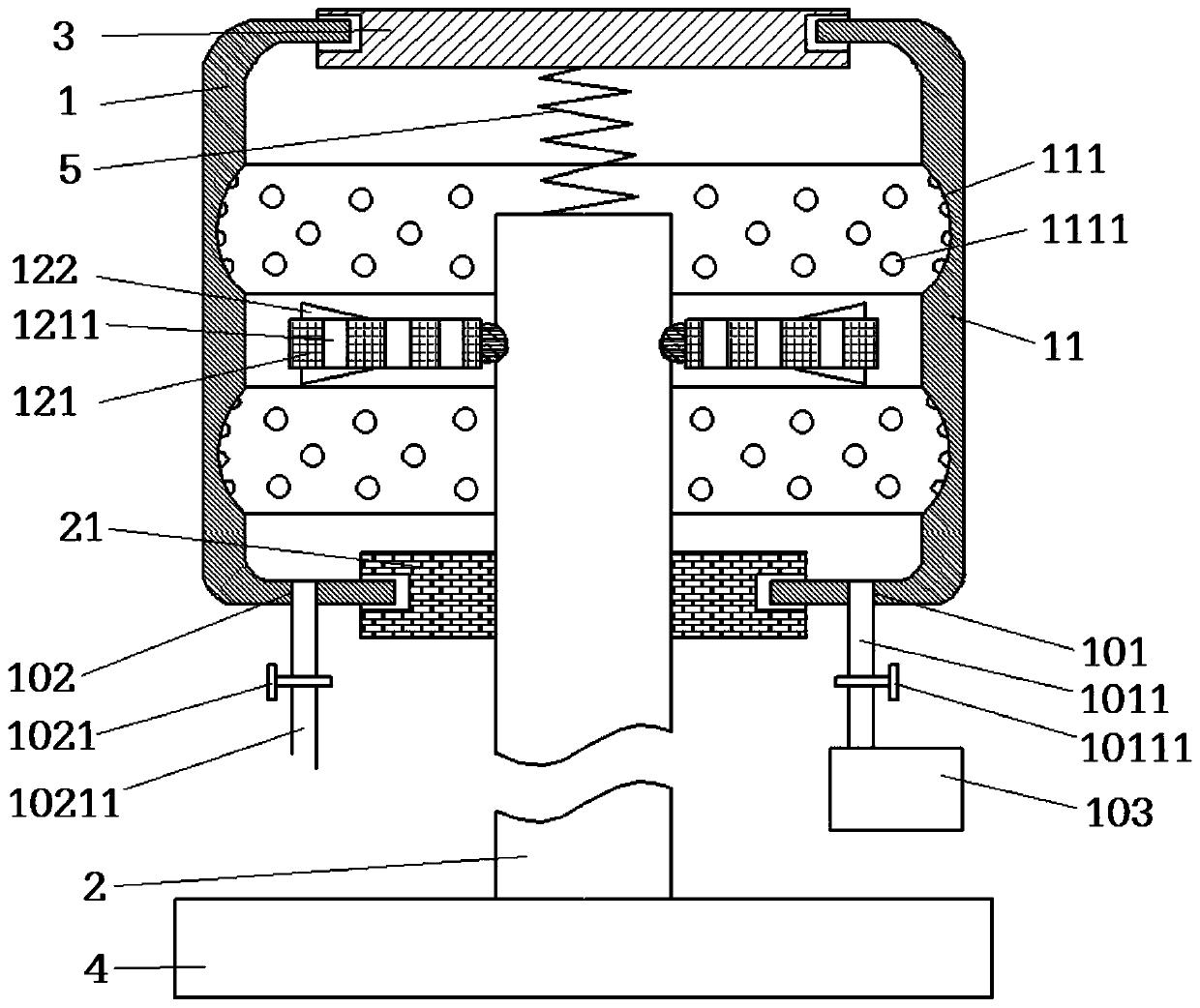

[0017] The air suspension system for vehicles, as shown in the figure, includes a shock absorber 2 and an air spring 1, and the outer wall of the shock absorber 2 is fixed with a shock absorber 21, and also includes an upper connection plate 3 and a lower connection plate 4, the upper connection The plate 3 is located above the shock absorbing rod 2, the lower connecting plate 4 is fixed on the lower end of the shock absorbing rod 2, the air spring 1 is sleeved on the upper end of the shock absorbing rod 2, the upper end of the air spring 1 is fixedly connected with the upper connecting plate 3, and the air spring The lower end of 1 is fixed on the shock absorbing ring 21, the air spring 1 is sealed and connected with the upper connecting plate 3 and the shock absorbing ring 21, and the upper and lower ends of the air spring 1 are provided with sealing rings and are respectively connected to the upper connecting plate through the sealing rings. 3 is connected with shock absorbi...

Embodiment 2

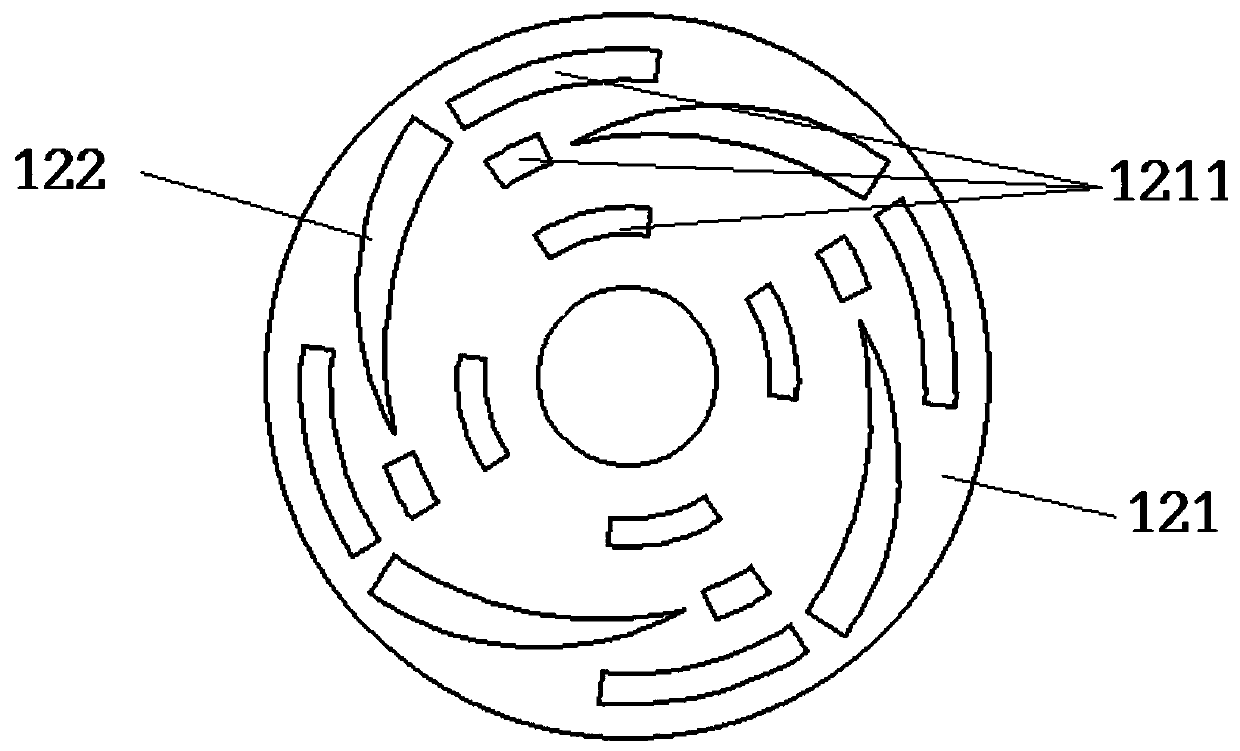

[0022] The same as Embodiment 1, the difference is that the air spring 1 includes a spring outer bag 11 and an air guiding device 12 installed in the spring outer bag 11, and also includes a shock-absorbing coil spring 5, which is located in the spring outer bag 11 Inside, the upper and lower ends of the shock-absorbing coil spring 5 are respectively pressed against the lower surface of the upper connecting plate 3 and the upper surface of the shock-absorbing rod 2; , the annular mounting plate 121 is installed on the outer wall of the upper end of the shock absorbing rod 2 and can be rotated on the axis of the shock absorbing rod 2 through the bearing. There is a gap of 20 mm between the annular mounting plate 121 and the inner wall of the spring outer bag 11. The mounting plate 121 is provided with a plurality of guide holes 1211, and the upper surface and the lower surface of the annular mounting plate 121 are provided with a plurality of arc-shaped plates 122, and the arc-s...

Embodiment 3

[0024] Same as Embodiment 2, the difference is that a gap of 27 mm is provided between the annular mounting plate 121 and the inner wall of the spring outer bag 11, and the height of the protrusion at the outer end of the arc-shaped plate 122 is 1.7 times the height of the protrusion at the inner end of the arc-shaped plate 122 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com