High elasticity modulus magnesium based composite with high strontium content and high aluminum content and preparation method for high elasticity modulus magnesium based composite

A technology of composite materials and high elasticity, applied in the field of magnesium alloy and magnesium-based composite materials, to achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

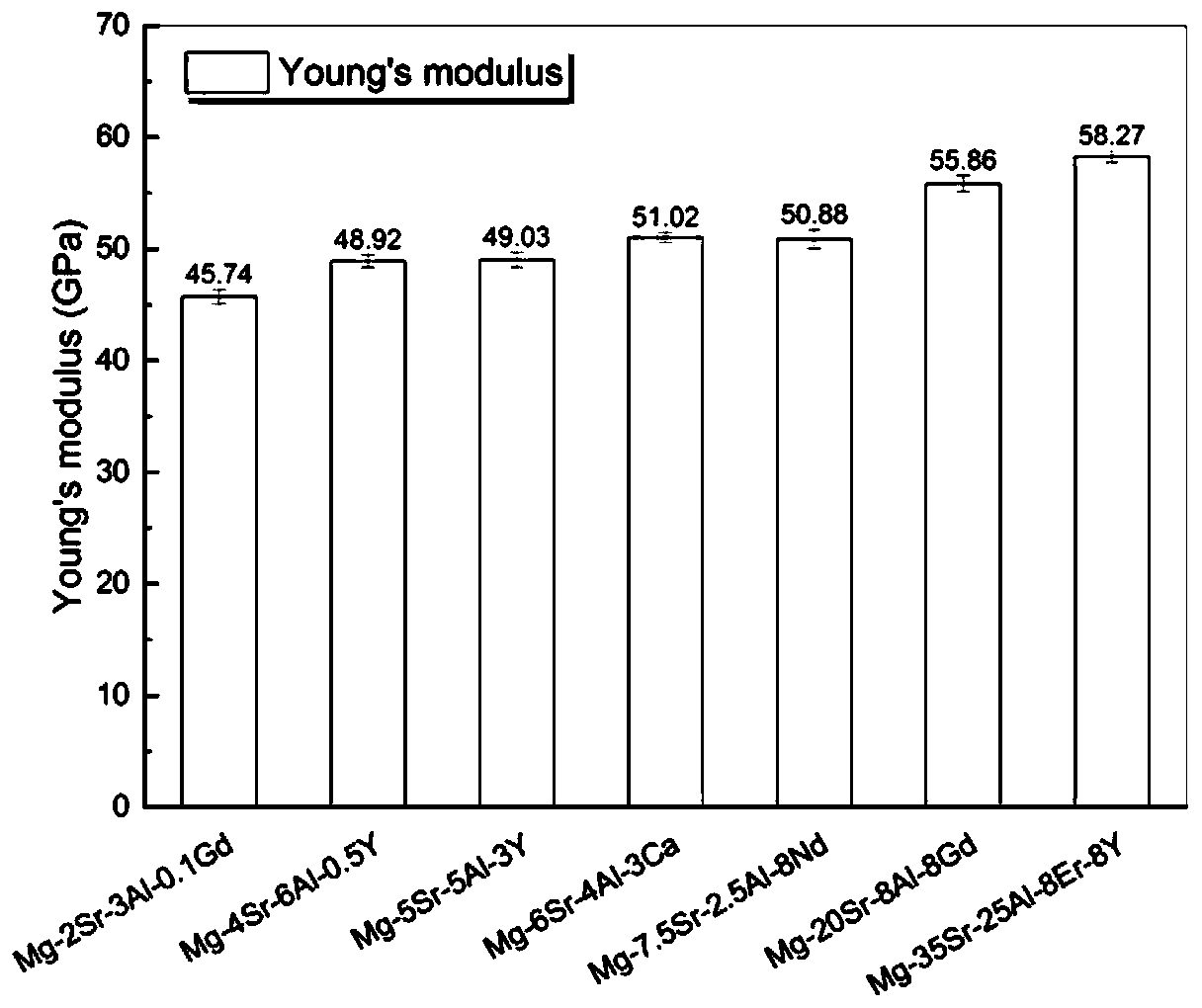

Embodiment 1

[0027] A high-elastic-modulus magnesium-based composite material with high strontium and high aluminum content, the components of the magnesium-based composite material are: Sr: 2wt.%, Al: 3wt.%, Gd: 0.1wt.%. , and the rest are Mg and impurities; Gd is a magnesium-gadolinium master alloy with a Gd content of 25wt.%, and the purity of other metals is above 99%.

[0028] A method for preparing a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, comprising the steps of:

[0029] (1) Prepare raw materials:

[0030] According to the mass percentage ratio of the components of a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, the required raw materials are weighed;

[0031] (2) Ingot melting:

[0032] First, in the smelting unit CO 2 +SF 6 Under the protection of protective gas, add pure magnesium, heat to 740 ° C and stir until it is completely melted, the CO 2 and SF 6 The volume ratio i...

Embodiment 2

[0039] A high-elastic-modulus magnesium-based composite material with high strontium and high aluminum content, the components of the magnesium-based composite material are: Sr: 4wt.%, Al: 6wt.%, Y: 0.5wt.%. , and the rest are Mg and impurities; wherein Y is a magnesium-yttrium master alloy with a Y content of 25wt.%, and the purity of other metals is above 99%.

[0040] A method for preparing a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, comprising the steps of:

[0041] (1) Prepare raw materials:

[0042] According to the mass percentage ratio of the components of a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, the required raw materials are weighed;

[0043] (2) Ingot melting:

[0044] First, in the smelting unit CO 2 +SF 6 Under the protection of protective gas, add pure magnesium, heat to 750 ° C and stir until it is completely melted, the CO 2 and SF 6 The volume ratio...

Embodiment 3

[0049] A high-elastic-modulus magnesium-based composite material with high strontium and high aluminum content, the components of the magnesium-based composite material are: Sr: 5wt.%, Al: 5wt.%, Y: 3wt.%. The rest is Mg and impurities; wherein Y is a magnesium-yttrium master alloy with a Y content of 25wt.%, and the purity of other metals is above 99%.

[0050] A method for preparing a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, comprising the steps of:

[0051] (1) Prepare raw materials:

[0052] According to the mass percentage ratio of the components of a high-strontium-high-aluminum-content high-elastic-modulus magnesium-based composite material, the required raw materials are weighed;

[0053] (2) Ingot melting:

[0054] First, in the smelting unit CO 2 +SF 6 Under the protection of protective gas, add pure magnesium, heat to 760 ° C and stir until it is completely melted, the CO 2 and SF 6 The volume ratio is 165:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com