A kind of fe-mn-cu-c alloy and its medical application

A technology of fe-mn-cu-c and alloy, which is applied in the field of implanted device materials, can solve problems such as blurred impact, heavy economic burden on patients and their families, and body inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

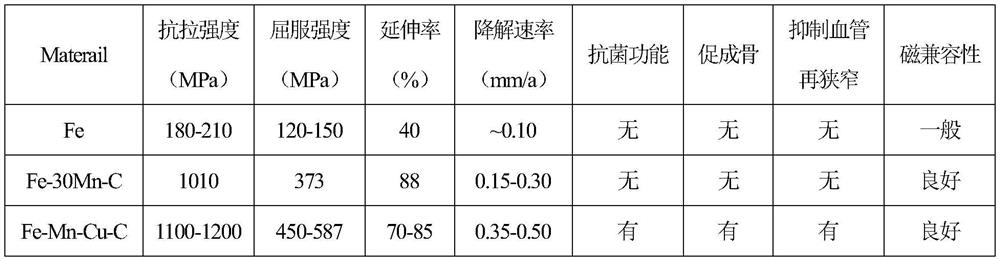

[0032] In this embodiment, Fe-Mn-Cu-C quaternary Fe alloy, the mass percentages are: Mn: 28%, C: 0.8%, Cu: 1.0%, and the rest is Fe, which is expressed as Fe-28Mn-0.8 C-1Cu. Fe alloy ingots were made by vacuum induction melting, and after the ingots were kept at 1100°C for 1 hour, they were forged into round bars of Φ20mm.

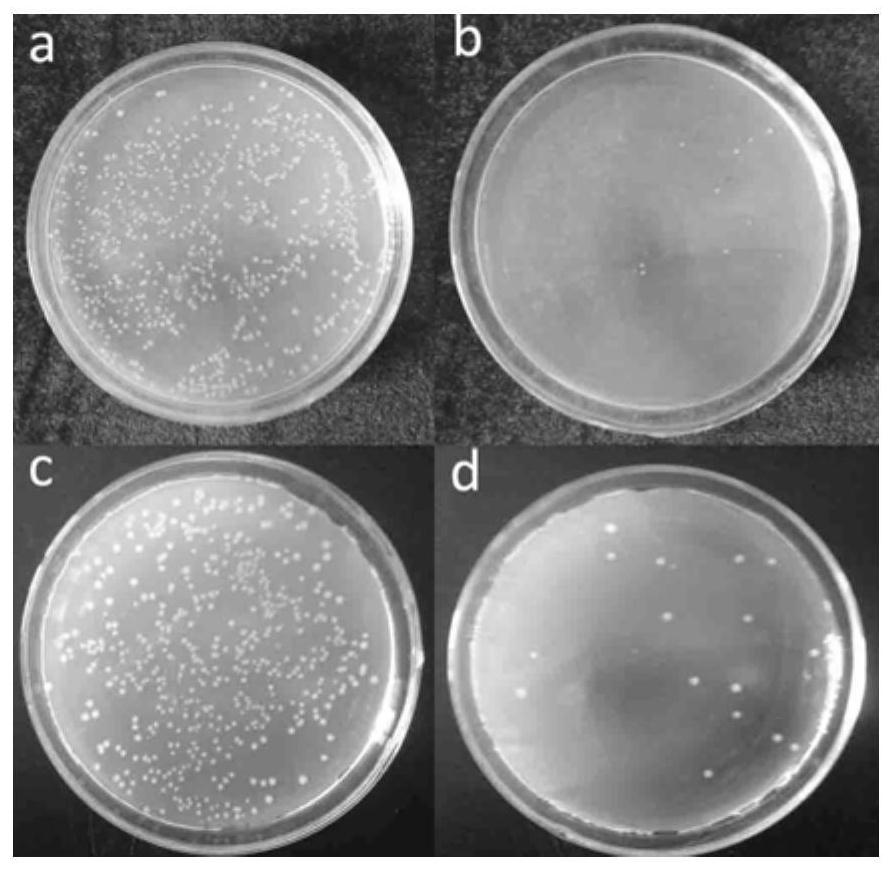

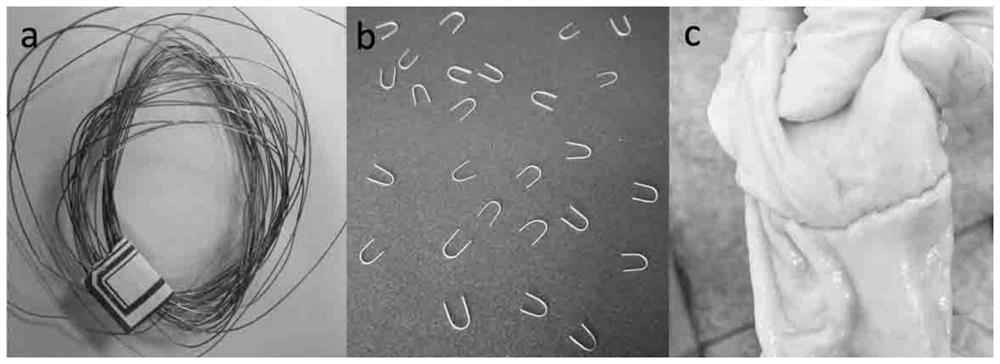

[0033] According to the GB / T 228-2002 standard, the Fe alloy bar was processed into a standard tensile specimen, and its tensile strength was 1130MPa, the yield strength was 453MPa, and the elongation was 83% measured on a universal mechanical testing machine. According to the antibacterial test standard GB / T2591, the alloy has a strong bactericidal function, and the bactericidal rates of Staphylococcus aureus and Escherichia coli are 96.0% and 98.1% respectively.figure 1 . According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.45mm / a when immersed in normal saline for 7 days, and the degradation rate decreases to 0.35mm / a af...

Embodiment 2

[0035] In this embodiment, Fe-Mn-Cu-C quaternary Fe alloy, the mass percentages are: Mn: 20%, C: 0.5%, Cu: 2.0%, and the rest is Fe, which is expressed as Fe-20Mn-0.5 C-2Cu. Fe alloy ingots were made by vacuum induction melting, and after the ingots were kept at 1100°C for 1 hour, they were forged into round bars of Φ20mm.

[0036] According to the GB / T 228-2002 standard, the Fe alloy bar was processed into a standard tensile sample, and its tensile strength was 1177MPa, the yield strength was 493MPa, and the elongation was 80% measured on a universal mechanical testing machine. According to the antibacterial test standard GB / T2591, the alloy has a strong bactericidal function, and the bactericidal rates against Staphylococcus aureus and Escherichia coli are 99.2% and 99.9%, respectively. According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.48mm / a when immersed in normal saline for 7 days, and the degradation rate decreases to 0.39mm / a after 14...

Embodiment 3

[0038] In this embodiment, Fe-Mn-Cu-C quaternary Fe alloy, the mass percentages are: Mn: 30%, C: 1.1%, Cu: 2.2%, and the rest is Fe, which is expressed as Fe-30Mn-1.1 C-2.2Cu. Fe alloy ingots were made by vacuum induction melting, and after the ingots were kept at 1100°C for 1 hour, they were forged into round bars of Φ20mm.

[0039] According to the GB / T 228-2002 standard, the Fe alloy bar was processed into a standard tensile specimen, and its tensile strength was 1200MPa, the yield strength was 584MPa, and the elongation was 76% measured on a universal mechanical testing machine. According to the antibacterial test standard GB / T2591, the alloy has a strong bactericidal function, and the bactericidal rates of Staphylococcus aureus and Escherichia coli are 99.9% and 99.9%, respectively. According to the ASMT-G31 metal immersion standard, the degradation rate can reach 0.50mm / a when immersed in physiological saline for 7 days, and the degradation rate decreases to 0.43mm / a af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com