A high-rigidity electric lift insulation cabin

An electric and electric technology of rigidity, applied in the field of high-stiffness electric lifting and insulation cabins, can solve the problems of self-locking stability safety hazards of the lifting mechanism, limitations of the lifting mechanism, etc., and achieve strong designability, good sealing, and thermal insulation performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

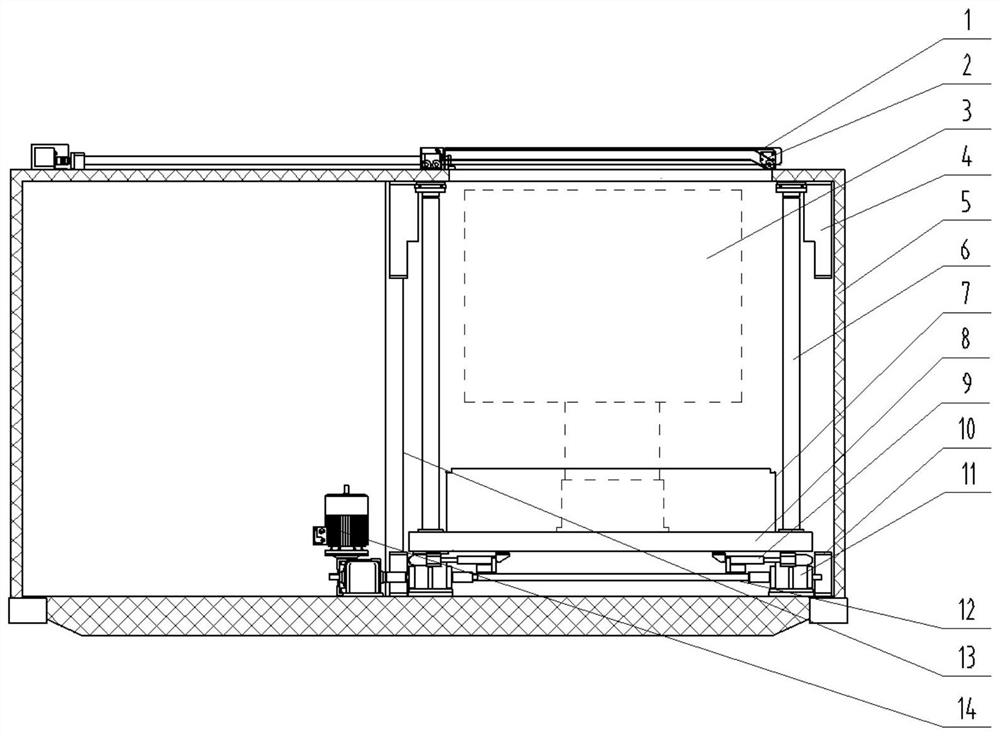

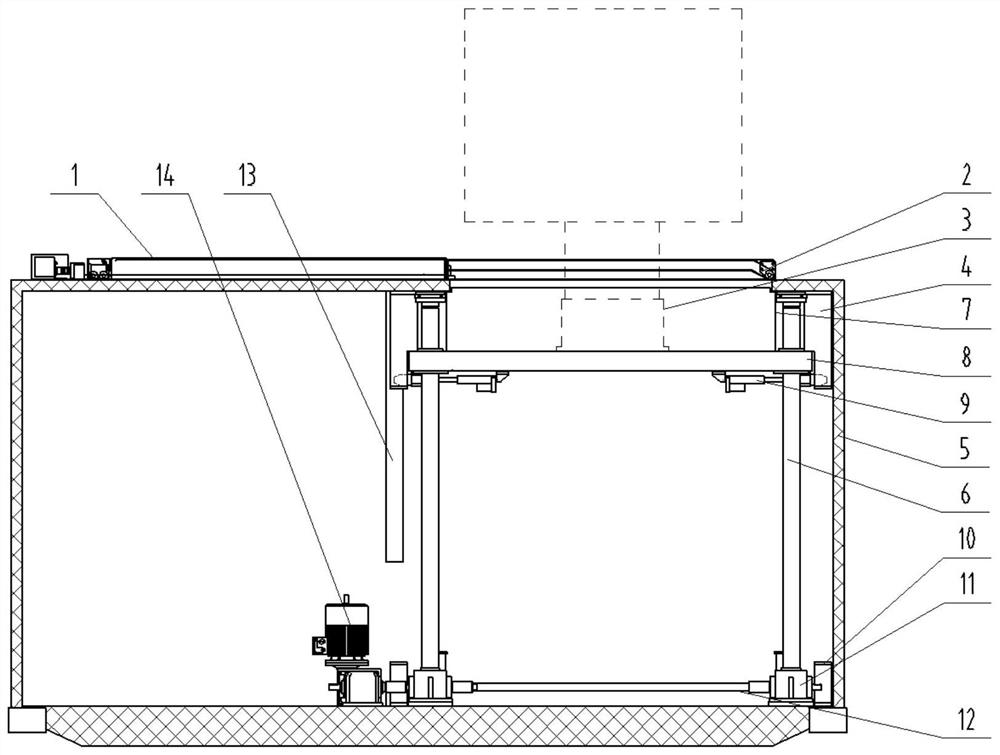

[0027] combined with figure 1 and 2As shown, a high-rigidity electric lifting insulation cabin includes a shelter 5 and a motor 14 arranged in the shelter 5. The top surface of the shelter 5 is provided with an opening, and the edge of the opening is provided with a top frame plate 2, and the top frame plate 2 is provided with an electric top cover 1; the shelter 5 is provided with 4 lead screw pairs 6 fixedly connected with the shelter 5 through a fixing device, the lower end of the lead screw pair 6 is provided with a commutator 11, and the upper end of the lead screw pair 6 A platform 8 is provided in common, on which a thermal insulation compartment 7 is provided, and an electric locking mechanism 9 is provided on the underside of the platform 8; Respectively matched with the commutator 11, the purpose of the present invention is to provide a high-rigidity electric lifting insulation cabin for the deficiencies in the existing shelter 5 lifting mechanism technology, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com