Air conditioner, operation control method and computer readable storage medium

An operation control and air conditioner technology, applied in air conditioning systems, space heating and ventilation, heating methods, etc., can solve the problems of reduced energy efficiency, large R&D costs, and long R&D time of air conditioners, and achieve the effect of improving indoor heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

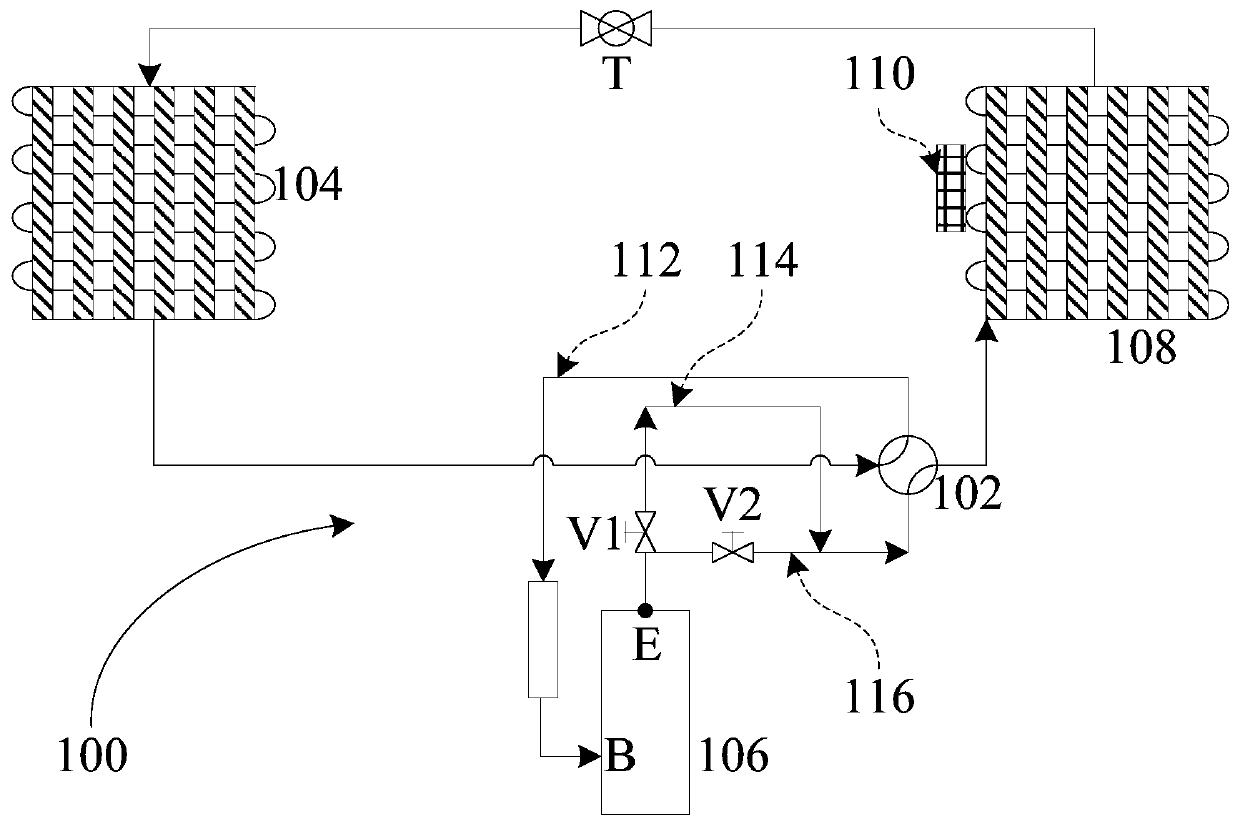

[0070] Such as figure 1 As shown, the air conditioner 100 runs in the cooling mode. After the temperature sensor 110 detects the outdoor working condition temperature signal of the outdoor heat exchanger 108, the controller performs comparison processing, and the controller detects that the outdoor working condition temperature signal is less than or When the temperature is equal to the preset temperature, the first electronic control valve V1 is controlled to be turned on, and the second electronic control valve V2 is controlled to be turned off. The high temperature and high pressure refrigerant circulating in the first exhaust branch pipe 114 exchanges heat with the low temperature and low pressure refrigerant in the return pipe 112 (Such as Figure 5 to Figure 7 The double dashed arrow shown indicates heat exchange).

Embodiment 2

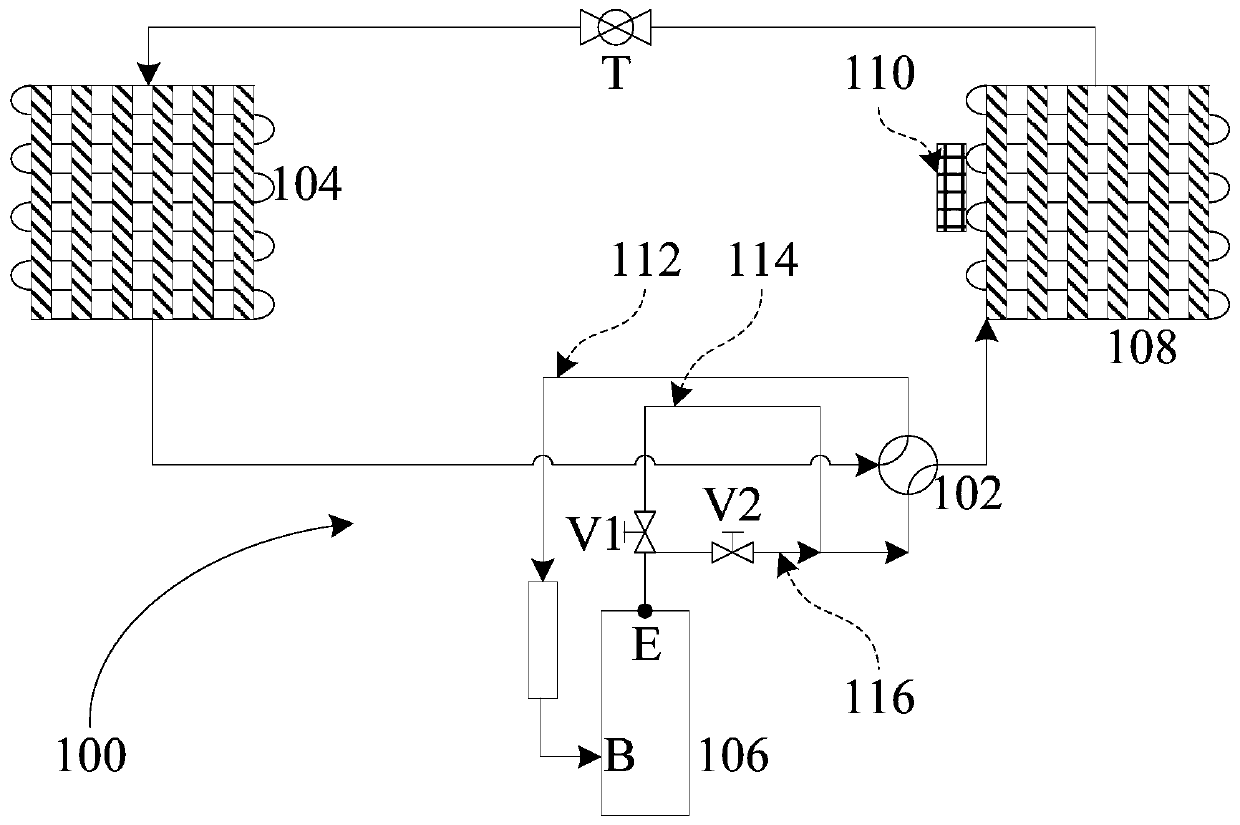

[0072] Such as figure 2 As shown, the air conditioner 100 is operating in the cooling mode. After the temperature sensor 110 detects the outdoor working condition temperature signal of the outdoor heat exchanger 108, the controller performs comparison processing, and the controller detects that the outdoor working condition temperature signal is greater than the expected temperature signal. When the temperature is set, the first electronic control valve V1 is controlled to be closed, and at the same time, the second electronic control valve V2 is controlled to conduct. The high temperature and high pressure refrigerant circulating in the first exhaust branch pipe 114 does not exchange heat with the low temperature and low pressure refrigerant of the return pipe 112 (such as Figure 5 to Figure 7 The double dashed arrow shown indicates heat exchange).

Embodiment 3

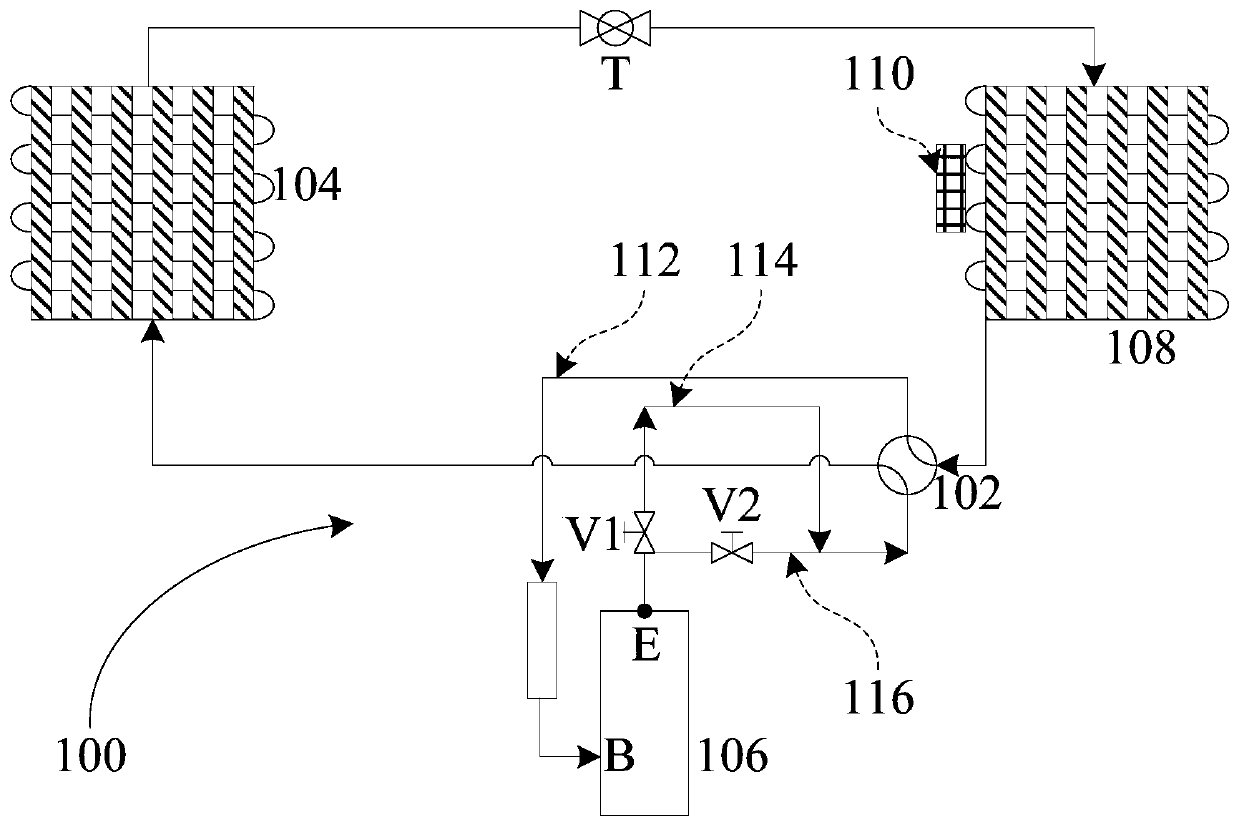

[0074] Such as image 3 As shown, after the conduction mode of the four-way valve 102 is switched, the air conditioner 100 runs in the heating mode. After the temperature sensor 110 detects the outdoor operating temperature signal of the outdoor heat exchanger 108, the controller performs comparison processing. When the controller detects that the outdoor working condition temperature signal is less than or equal to the preset temperature, it controls the first electronic control valve V1 to be turned on, and at the same time, controls the second electronic control valve V2 to be turned off, and the high temperature and high pressure refrigerant flowing in the first exhaust branch pipe 114 Perform heat exchange on the low temperature and low pressure refrigerant in the return pipe 112 (e.g. Figure 5 to Figure 7 The double dashed arrow shown indicates heat exchange).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com