Preparative thin layer chromatograph and using method thereof

A technology of thin-layer chromatograph and thin-layer chromatographic plate, which is applied in the field of chemical instruments, can solve the problems of analysis failure, affecting the analysis precision and accuracy of compound separation effect, and the undetermined rate of developing agent development, etc., to achieve the goal of ensuring accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

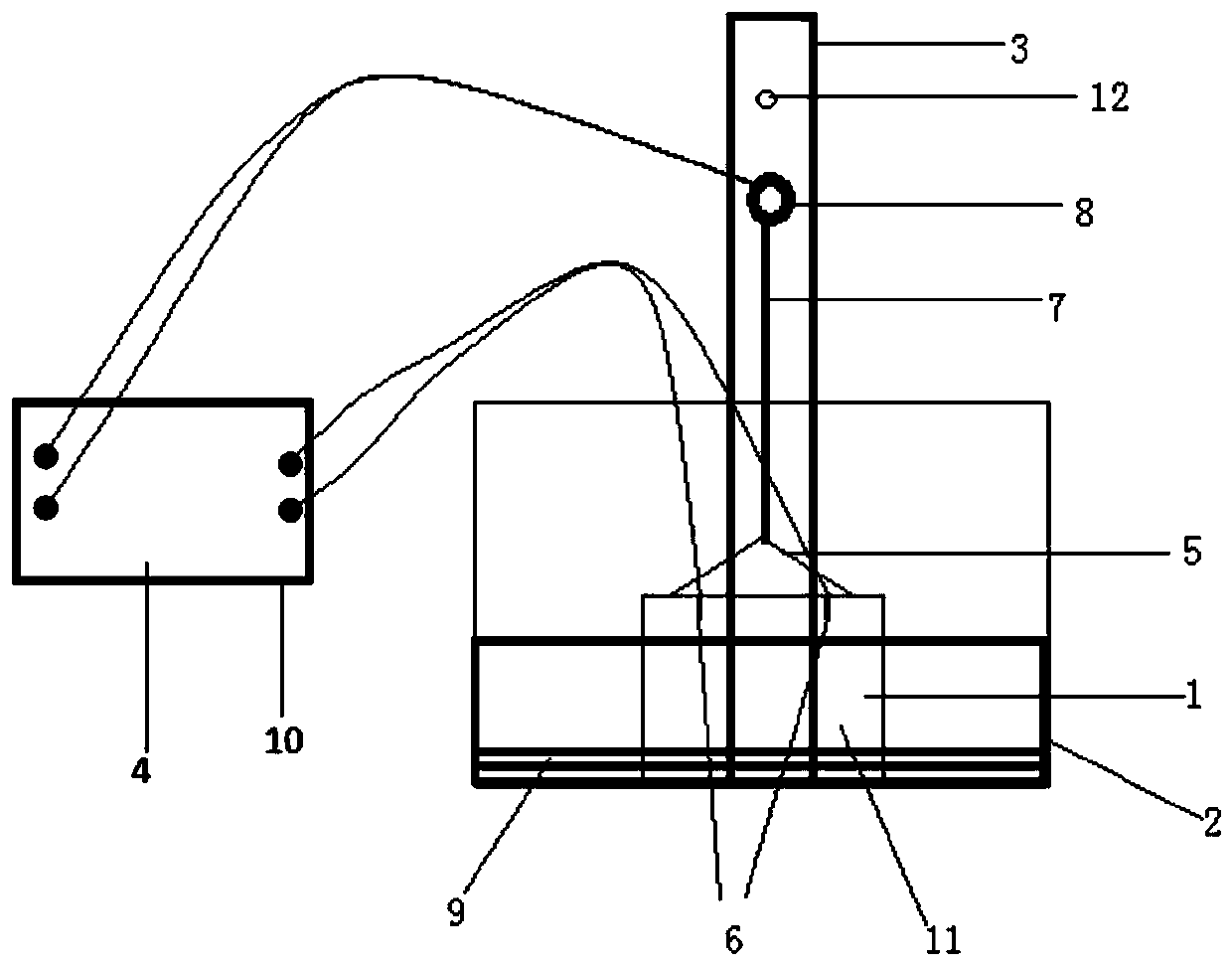

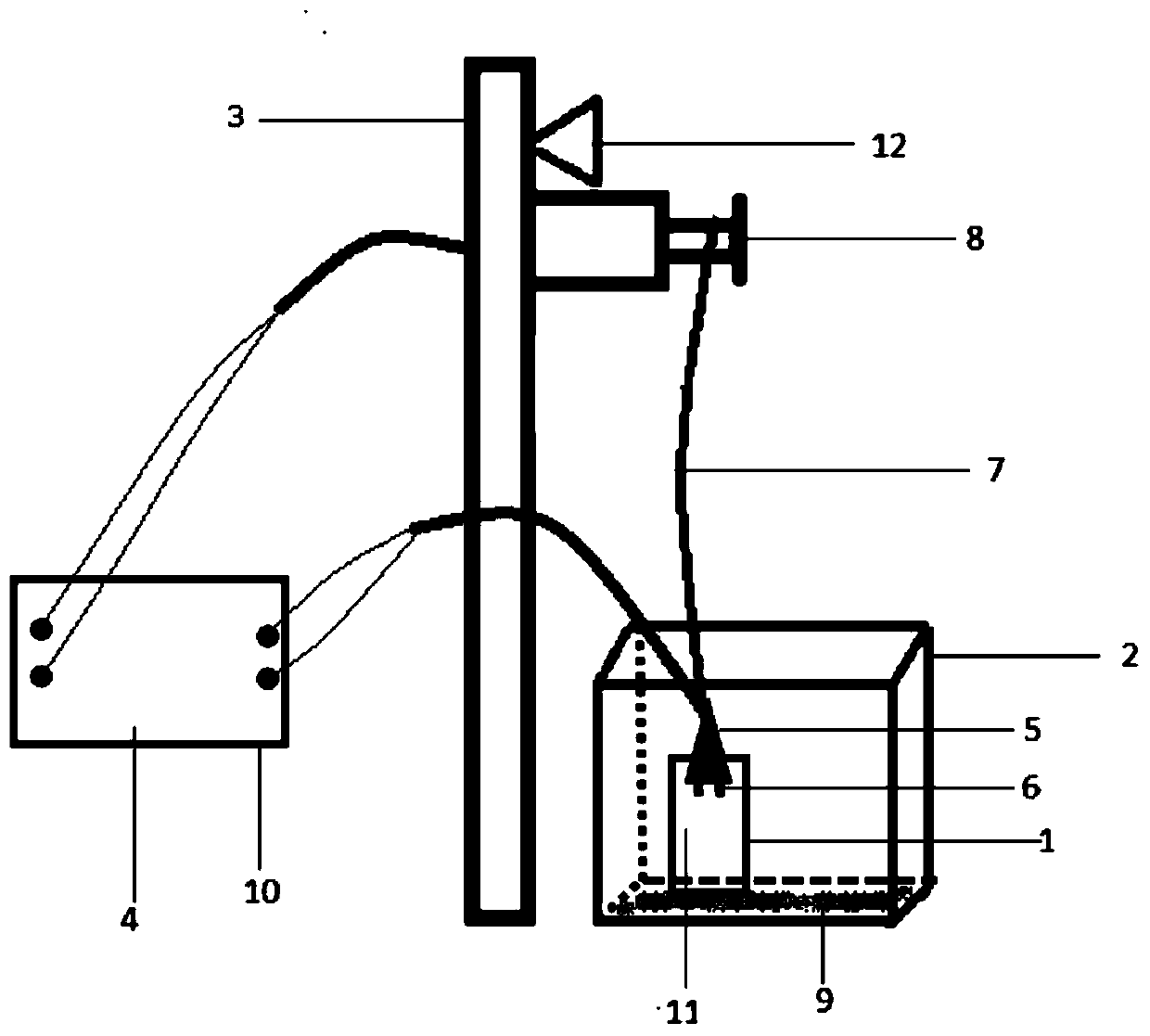

[0026] Such as figure 2 As shown, a preparative thin-layer chromatograph of the present invention includes a thin-layer chromatographic plate 1, an unfolding cylinder 2, and a support frame 3. The upper end of the thin-layer chromatographic plate is clamped with a plastic clip 5, and the clamping mouth of the plastic clip has Two separate electrodes 6, the plastic clip 5 is connected to the stepping motor shaft 8 through a flexible wire 7, the electrode 6 and the stepping motor are electrically connected to the circuit board 4; the thin layer chromatography plate 1 is A rectangular plate, one side of which is coated with a stationary phase layer, the stationary phase layer has a length of 10-30 cm, a width of 10-30 cm, and a thickness of 0.5-2.0 mm. Two separate electrodes with a plastic clip 6 is close to the upper end of the stationary phase layer; the thin-layer chromatography plate 1 is placed vertically in the unfolding cylinder 2. The stationary phase layer is a silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com