Composite stent material preparation method, product and application method thereof

A technology of composite scaffold and application method, which is applied in the field of preparation of composite scaffold materials, can solve problems such as limiting the application of hydroxyapatite powder, failing to meet the repair mechanical strength, and lacking controllability of drug sustained release, so as to facilitate large-scale promotion, Improve the mechanical properties and stability of aqueous solution, the effect of controllable degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

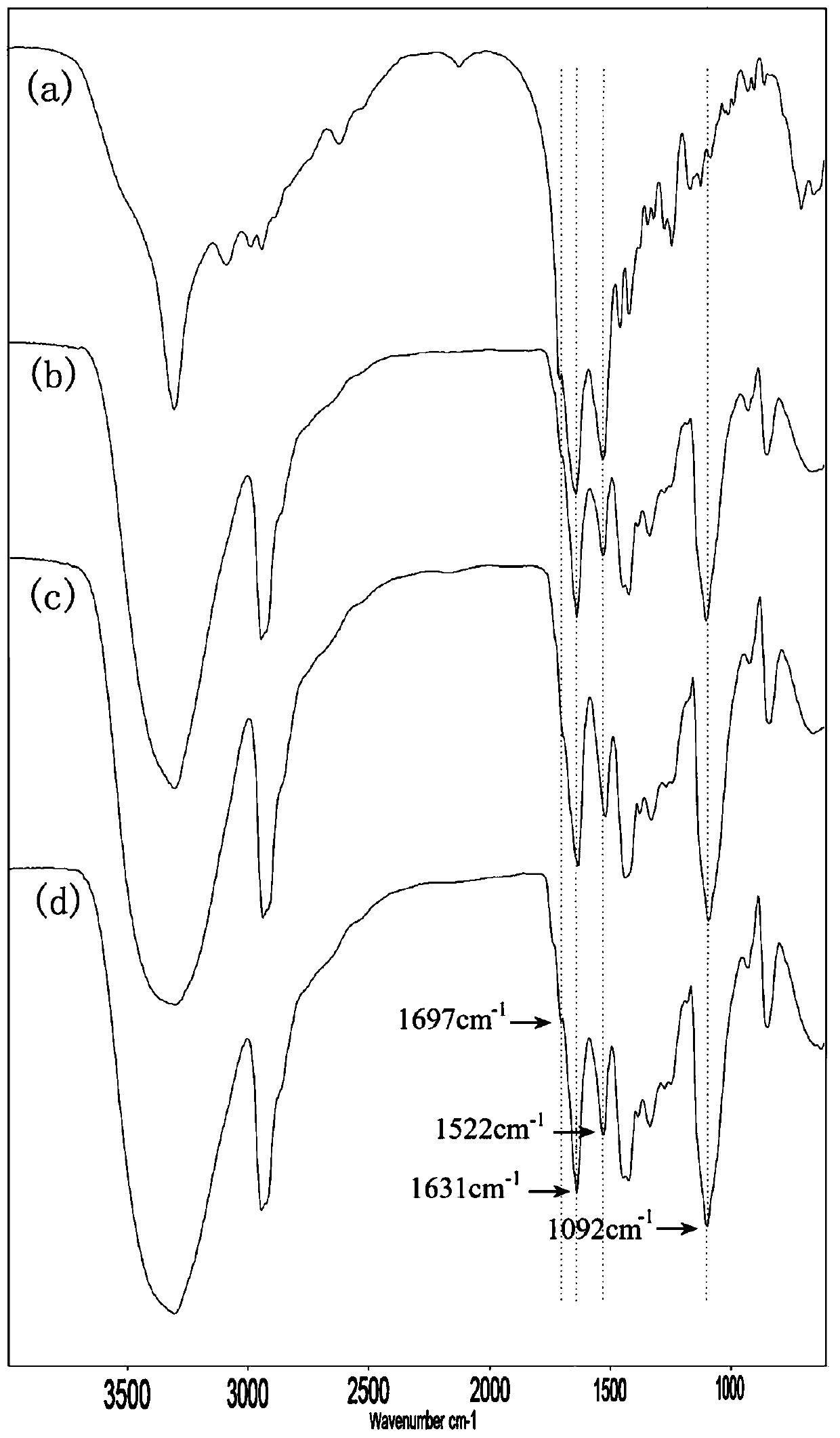

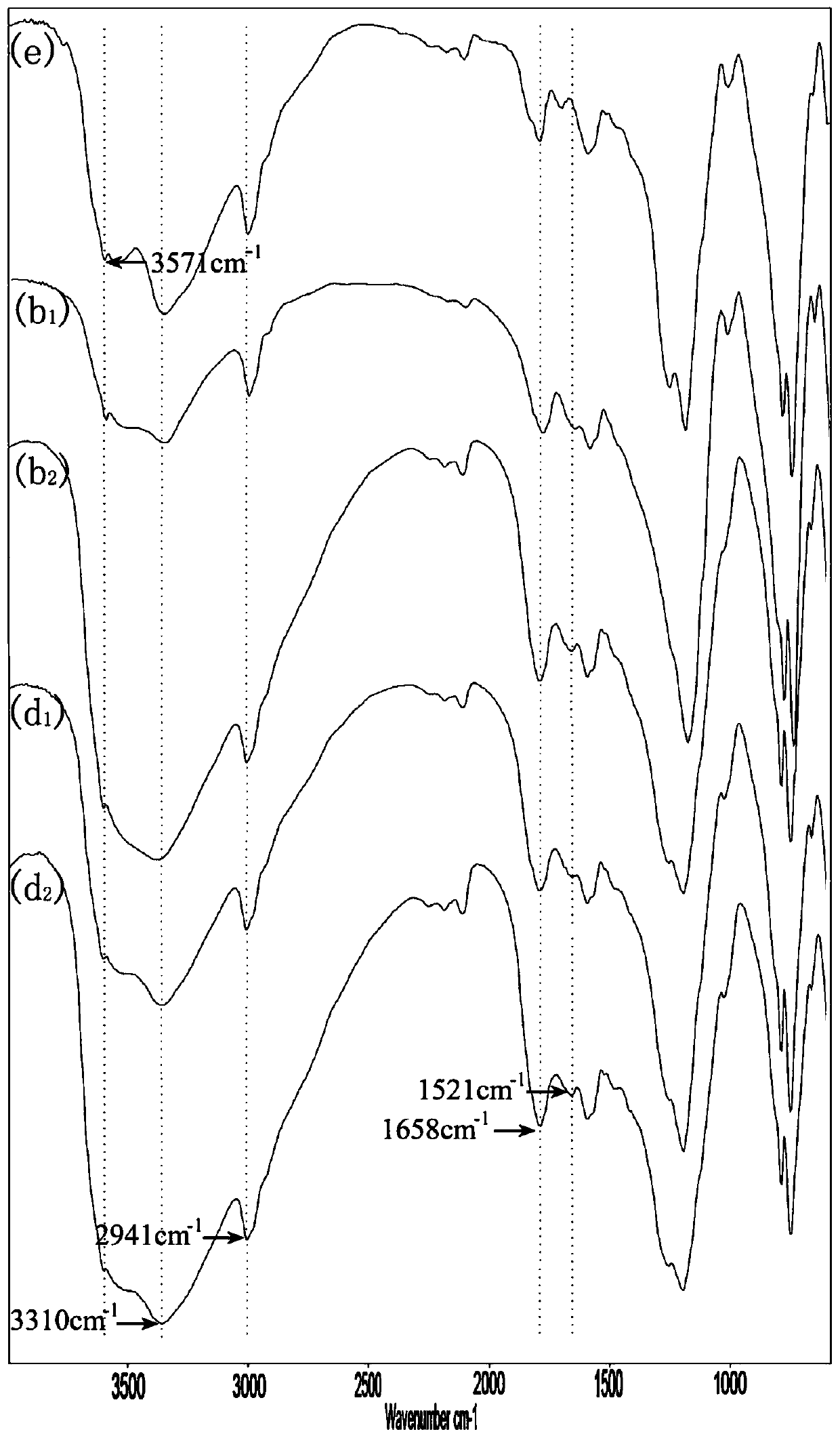

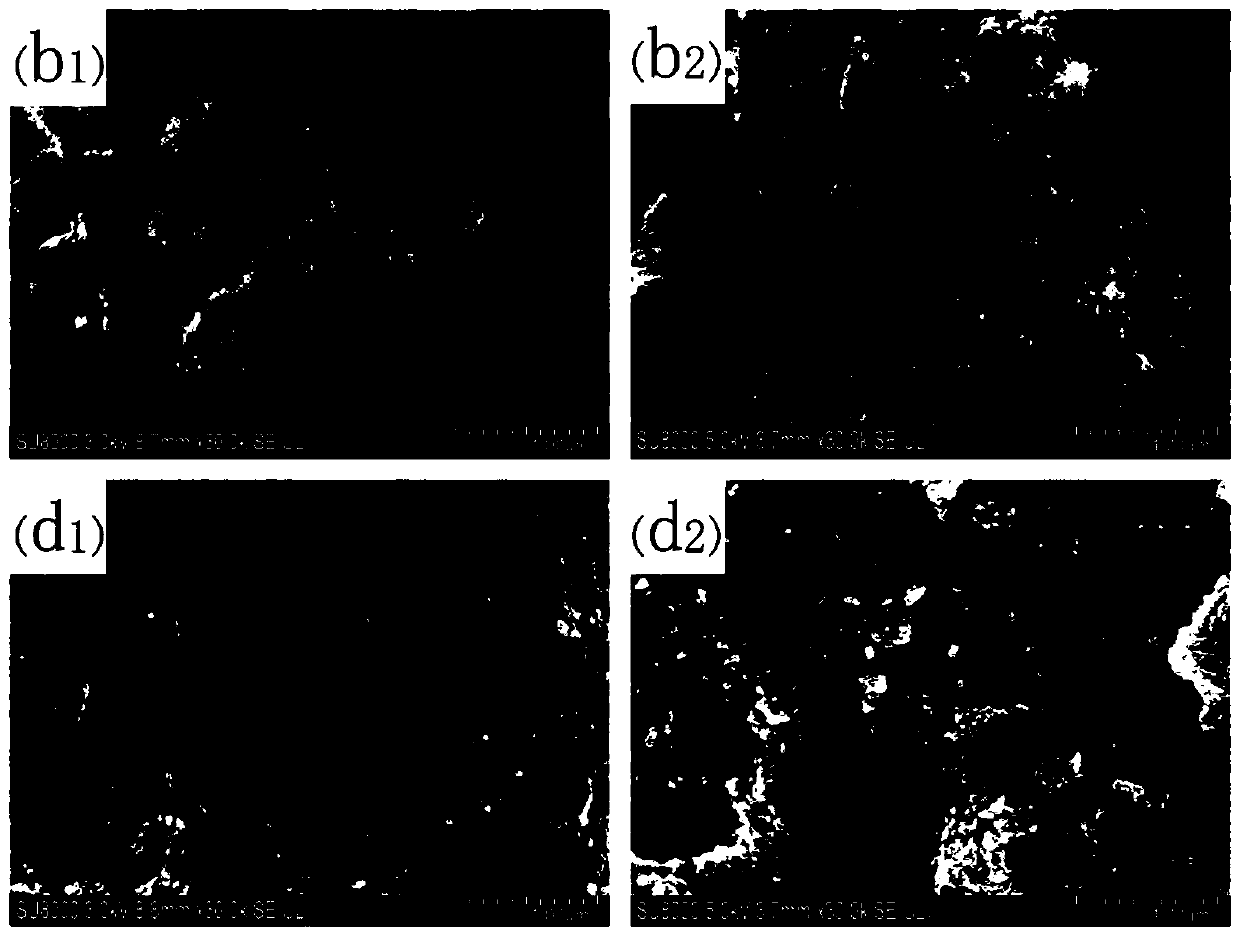

[0037] Example 1: Weigh 1 g of silk fibroin powder extracted by high-pressure degumming and 4 g of polyvinyl alcohol powder, blend the silk fibroin powder and polyvinyl alcohol powder with 35 g of distilled water, stir evenly, heat to 99 ° C in a water bath, and keep warm It was fully dissolved for 1 hour to prepare a composite hydrogel, that is, a silk fibroin / polyvinyl alcohol composite hydrogel with a concentration of 12%. The composite hydrogel was placed at -24°C for 8 hours, then placed at room temperature at 20°C for 4 hours to thaw, repeated freezing-thawing 3 times, and then placed in a water bath at 80°C for 0.5 hours. Weighing 1.8g of hydroxyapatite powder and 1g of composite hydrogel were fully stirred to make them uniformly mixed to obtain a composite scaffold material, that is, a silk fibroin / polyvinyl alcohol / hydroxyapatite composite material was obtained.

[0038] 3D printing equipment is used to quantitatively print the composite scaffold material. The specifi...

Embodiment 2

[0039]Example 2: Weigh 1 g of silk fibroin powder extracted by high-pressure degumming and 4 g of polyvinyl alcohol powder, blend the silk fibroin powder and polyvinyl alcohol powder with 35 g of distilled water, stir evenly, heat to 99 ° C in a water bath, and keep warm It was fully dissolved for 1 hour to prepare a composite hydrogel, that is, a silk fibroin / polyvinyl alcohol composite hydrogel with a concentration of 12%. The composite hydrogel was placed at -24°C for 8 hours, then placed at room temperature at 20°C for 4 hours to thaw, repeated freezing-thawing 3 times, and then placed in a water bath at 80°C for 0.5 hours. Weighing 1.8g of hydroxyapatite powder and 1g of composite hydrogel were fully stirred to make them uniformly mixed to obtain a composite scaffold material, that is, a silk fibroin / polyvinyl alcohol / hydroxyapatite composite material was obtained.

[0040] 3D printing equipment is used to quantitatively print the composite scaffold material. The specific...

Embodiment 3

[0041] Example 3: Weigh 1 g of silk fibroin powder extracted by high-pressure degumming and 4 g of polyvinyl alcohol powder, blend the silk fibroin powder and polyvinyl alcohol powder with 35 g of distilled water, stir evenly, heat to 99 ° C in a water bath, and keep warm It was fully dissolved for 1 hour to prepare a composite hydrogel, that is, a silk fibroin / polyvinyl alcohol composite hydrogel with a concentration of 12%. Put the composite hydrogel at room temperature of 20°C for 36 hours; then weigh 1.8g of hydroxyapatite powder and 1g of composite hydrogel and mix them well to make a composite scaffold material, that is, Silk fibroin / polyvinyl alcohol / hydroxyapatite composite.

[0042] 3D printing equipment is used to quantitatively print the composite scaffold material. The specification is 10×10×10mm 3 The three-dimensional porous structure scaffold, the three-dimensional porous structure scaffold was placed under the condition of -24 ℃ for 48 hours to freeze-dry, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap