Mixed feed system of variable-flow foam and fire fighting truck

A supply system and variable flow technology, applied in the field of variable flow foam mixing supply system and fire trucks, can solve the problems of unable to grasp the spray distance, unable to control the amount of foam, waste the environment, etc., to save fire extinguishing time, maximize the spray distance, The effect of reducing property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

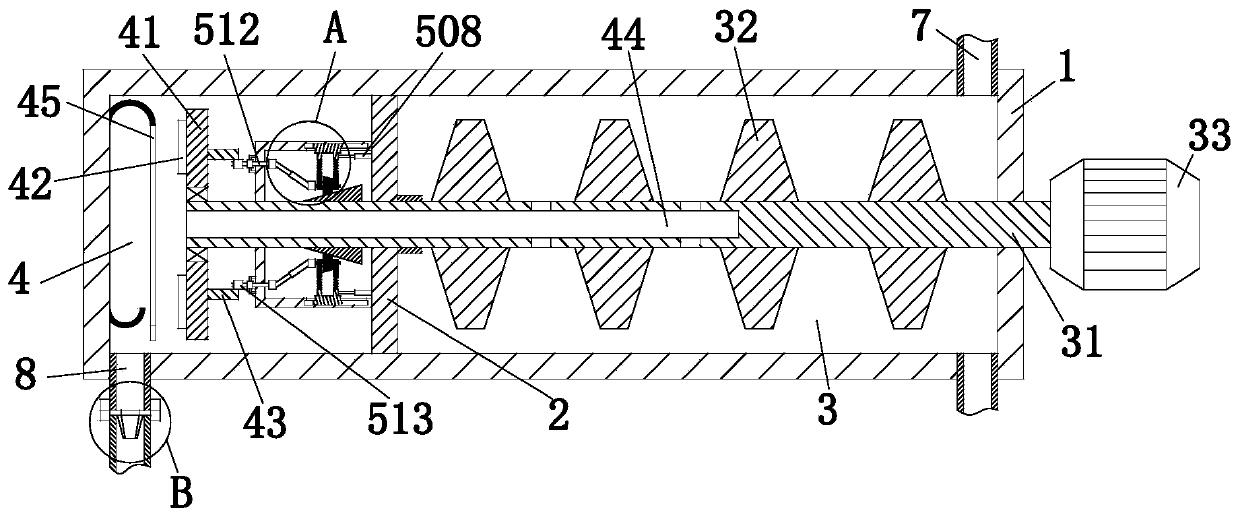

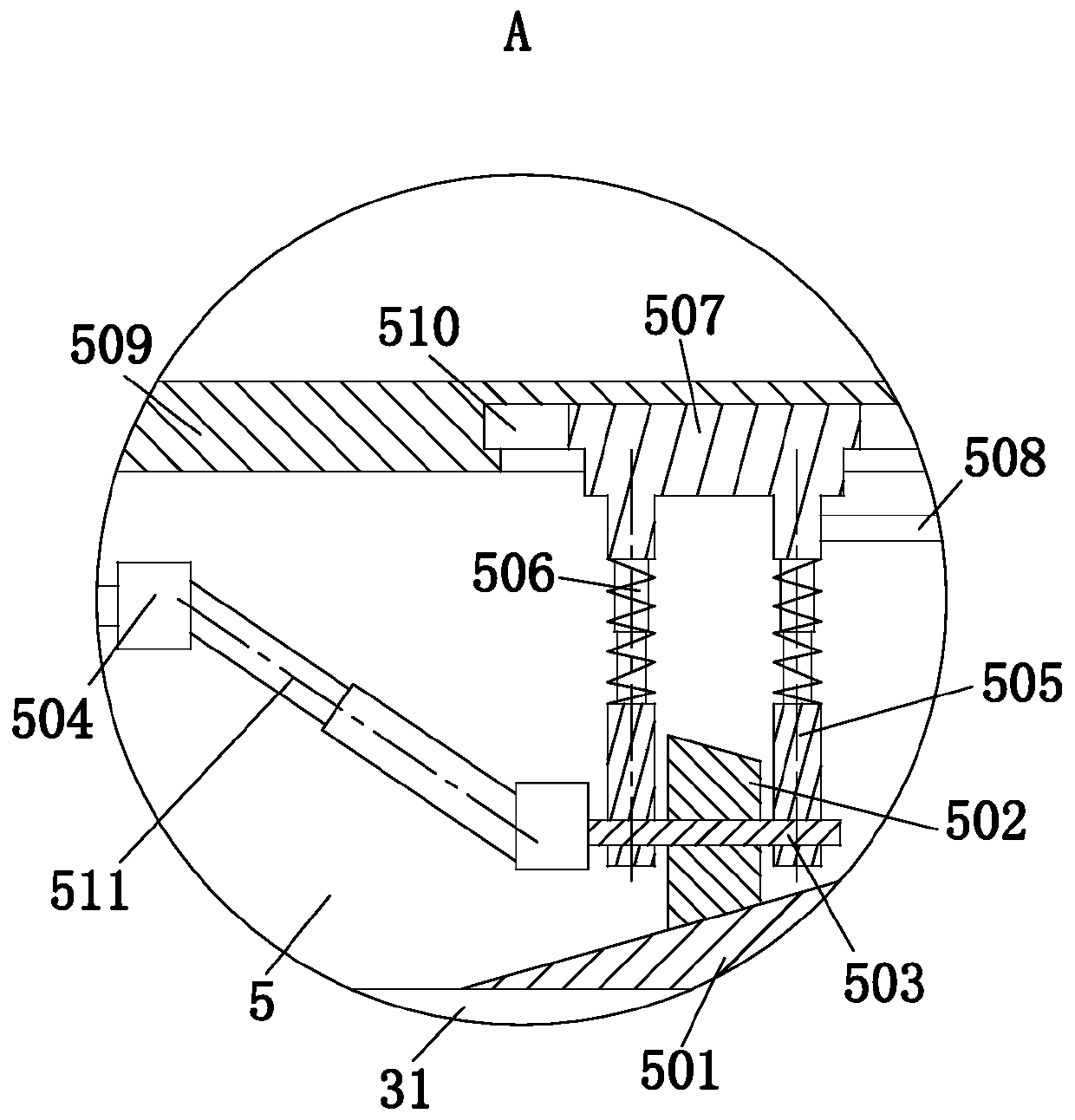

[0022] use Figure 1-Figure 6 A variable flow foam mixing supply system and a fire truck according to an embodiment of the present invention will be described as follows.

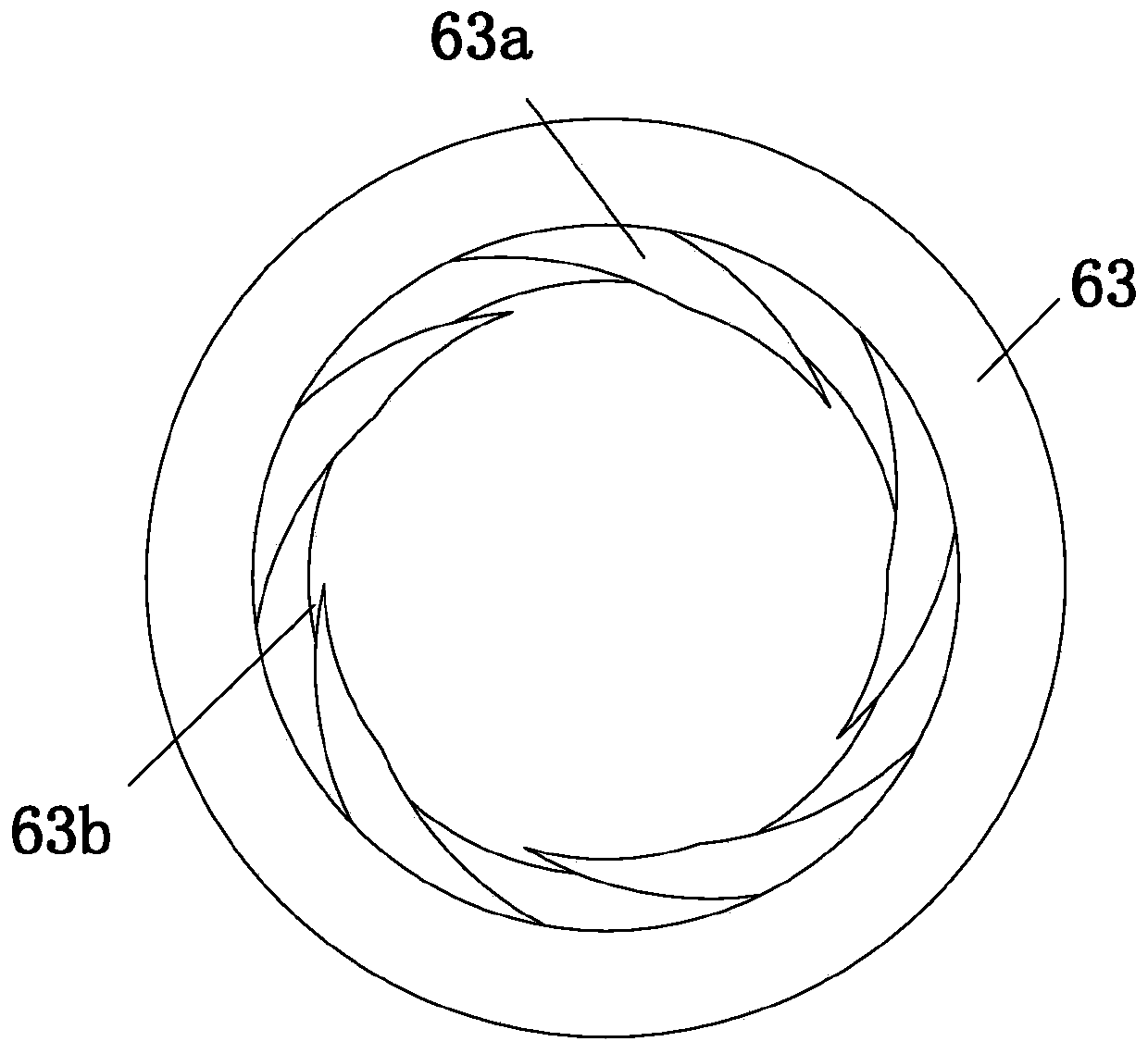

[0023] Such as Figure 1-Figure 6As shown, a variable flow foam mixing supply system according to the present invention includes a frame body 1, a separation plate 2, a mixing mechanism 3, a centrifugal mechanism 4, a power transmission mechanism 5 and a flow regulating mechanism 6; the frame body 1 It is in the shape of a cylinder, a liquid inlet pipe 7 is fixedly installed in the right end wall of the frame body 1, and a mixing and stirring mechanism 3 is provided at the right end inside the frame body 1; the mixing and stirring mechanism 3 is composed of a stirring rod 31, a stirring block 32 and a motor 33; The stirring rod 31 is inserted and rotated inside the frame body 1, the left side of the stirring rod 31 is rotated and connected to the middle part of the isolation plate 2, the right end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com