Motorcycle carburetor

A carburetor and motorcycle technology, applied in the direction of machine/engine, etc., can solve the problems of accelerated engine wear, prolonged exhaust gas combustion, high temperature of engine and exhaust pipe, etc., to reduce body vibration, prolong power life, and reduce combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

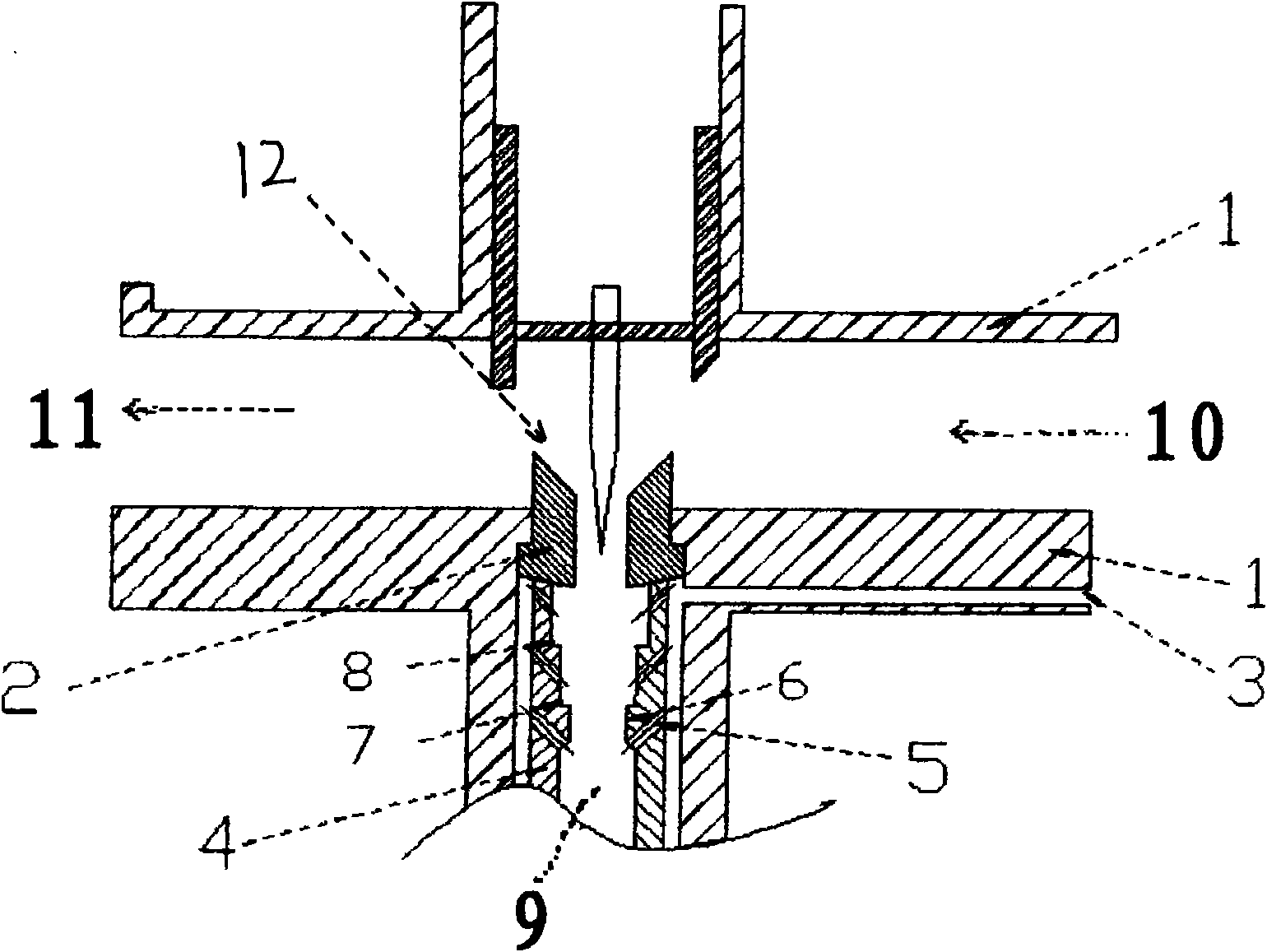

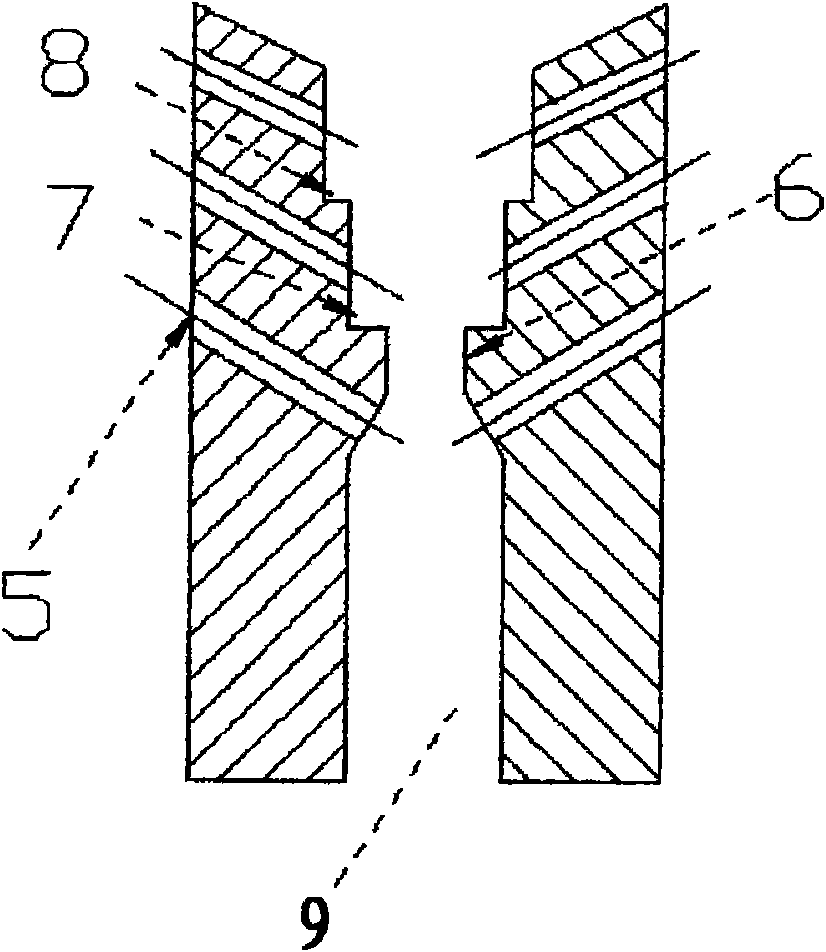

[0008] As can be seen from Figure (1), the present invention has a carburetor body 1, a main nozzle 2, a limited intake hole 3, an oil passage sleeve 4, an air 10, a mixed gas 11, and a mixing chamber 12. The through hole 5 on the oil channel sleeve 4 is inclined toward the fuel direction 9, and there are necks 6, steps 7 and 8 in the pipe. When the top of the casing sucks air, the air entering from the air intake hole 3 will reversely impact the oil when passing through the through hole 5 of the oil channel casing, and the oil is more likely to mix with the air when it is impacted. When the mixed gas passes through the neck 6, the flow velocity is accelerated and the mixing ratio quality is improved. When the mixed gas passes through the steps 7 and 8, the air strikes it in reverse again. After being impacted, the mixing is accelerated, the concentration of the mixing ratio in the first step is reduced, and favorable conditions are provided for the full mixing of the mixed ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com